Let's first take a look at the automotive industry: What challenges are carmakers currently facing, and what role does 5G play in this?

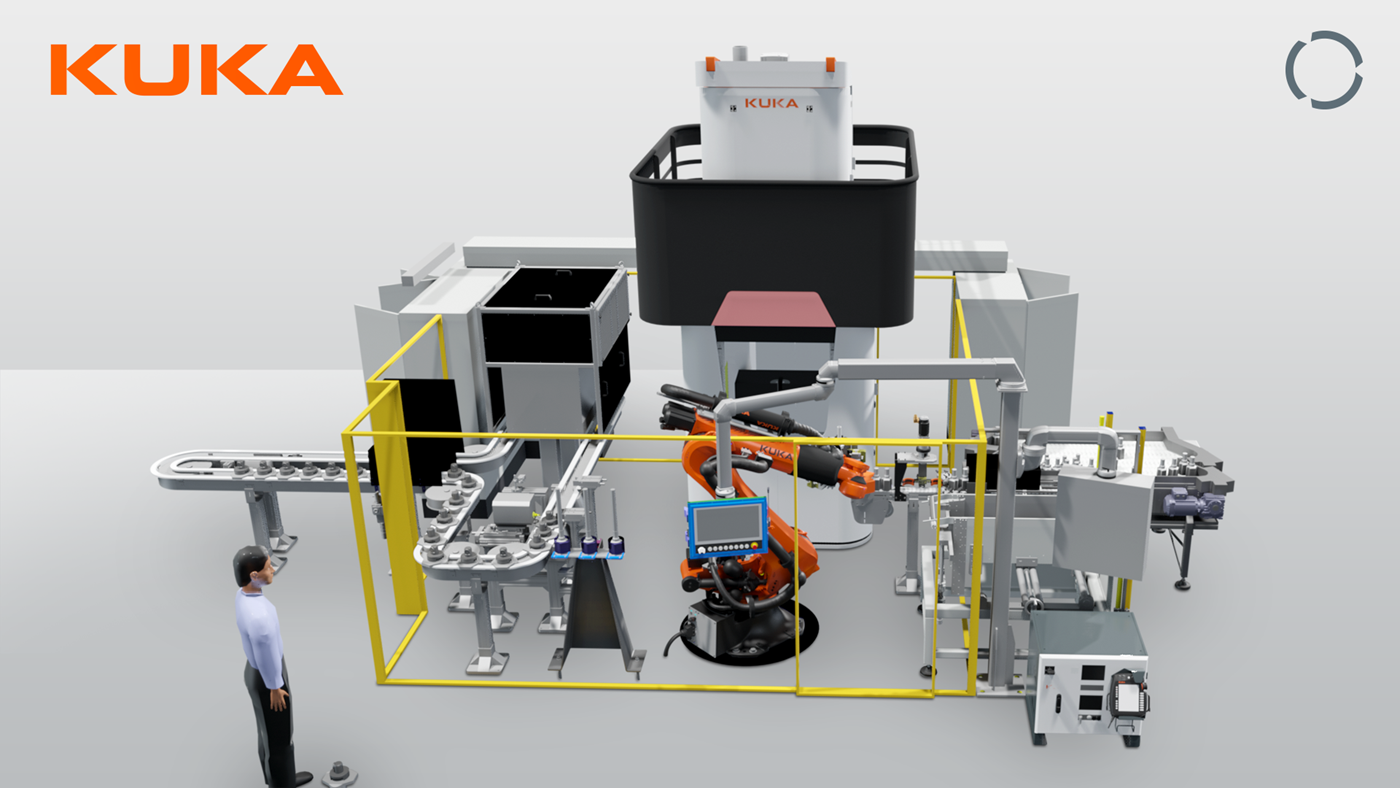

Matthias Paukner: Type diversity is increasing, models change frequently and batch sizes fluctuate greatly. The ability to plan the automotive market has become much more complex. Current trends require maximum flexibility and reaction speed for both the automotive manufacturer and the supplier. In this context, 5G promises: high bandwidth paired with high reliability, which is essential especially in production, as any downtime has a direct economic impact. This offers our customers the opportunity to network their production with a single radio technology. In the next few years, however, 5G will initially still be a complementary technology. Nevertheless, it is our goal to already include this technology in both product development and plant planning.

How is 5G currently developing?

Matthias Paukner: At the time of the introduction of the 5G mobile communications standard, the focus with Release 15 was initially on classic mobile communications with the desire for high data rates. With Releases 16 and 17, the focus is shifting to realtime capabilities, reliability and energy consumption - in other words, precisely those topics that are relevant for industry. In the industrial environment, this will gradually increase the range of functions in the coming years. Currently, however, the technology is still in a development status.