40 percent productivity boost and increased safety

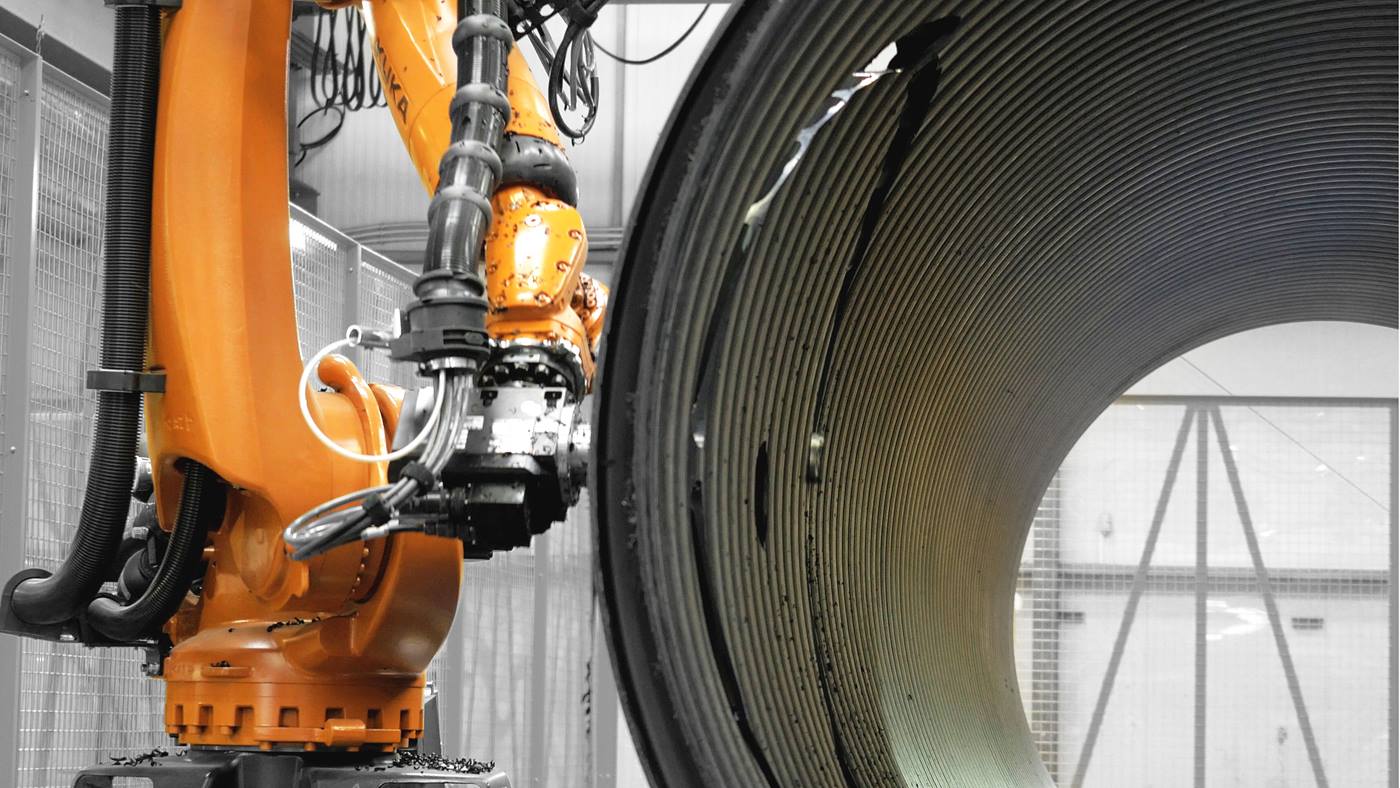

“Thanks to the KUKA 120 R2700 extra HA robot, our employees are relieved of very strenuous manual work involving strong vibrations,” says Graham Bennett. “The solution has enabled us to increased productivity by more than 40 percent,” says Asset’s Operation Manager with pleasure. “Shorter production times have allowed us to boost capacity by more than 50 percent. At the same time, there has been a significant improvement in quality and precision,” he emphasizes.

Thanks to its modular design tailored to the customer’s requirements, the system can be adapted to the needs of Asset International at any time. The integrator is also very pleased with the result. “We are very proud to have designed the first system worldwide that can process such large plastic parts with this precision and speed – all the while increasing occupational safety,” emphasizes Manuel Kratz, head of the project at Riexinger. For this reason, the Bad Liebenzell-based company is sure that robot-based automation in the plastics processing sector will be seeing further growth.

Find out more about the KUKA KR QUANTEC series