More than 80,000 door panels leave the plant of Meiller Aufzugtüren in Munich every year – and the trend is rising. What makes this statistic special is that hardly any door panel is identical to another. Passenger and goods elevators are always tailor-made, customer-specific solutions that are precisely adapted to the technical requirements of the building they are in. Meiller delivers door panels in infinitely variable dimensions.

Ultra-small batch sizes and countless variants

Small to ultra-small batch sizes and an endless procession of different variants have to be dealt with. These factors call for production systems that can rise to the challenge of the requirements involved, without problems.

KR C4 copes with the limitless variety

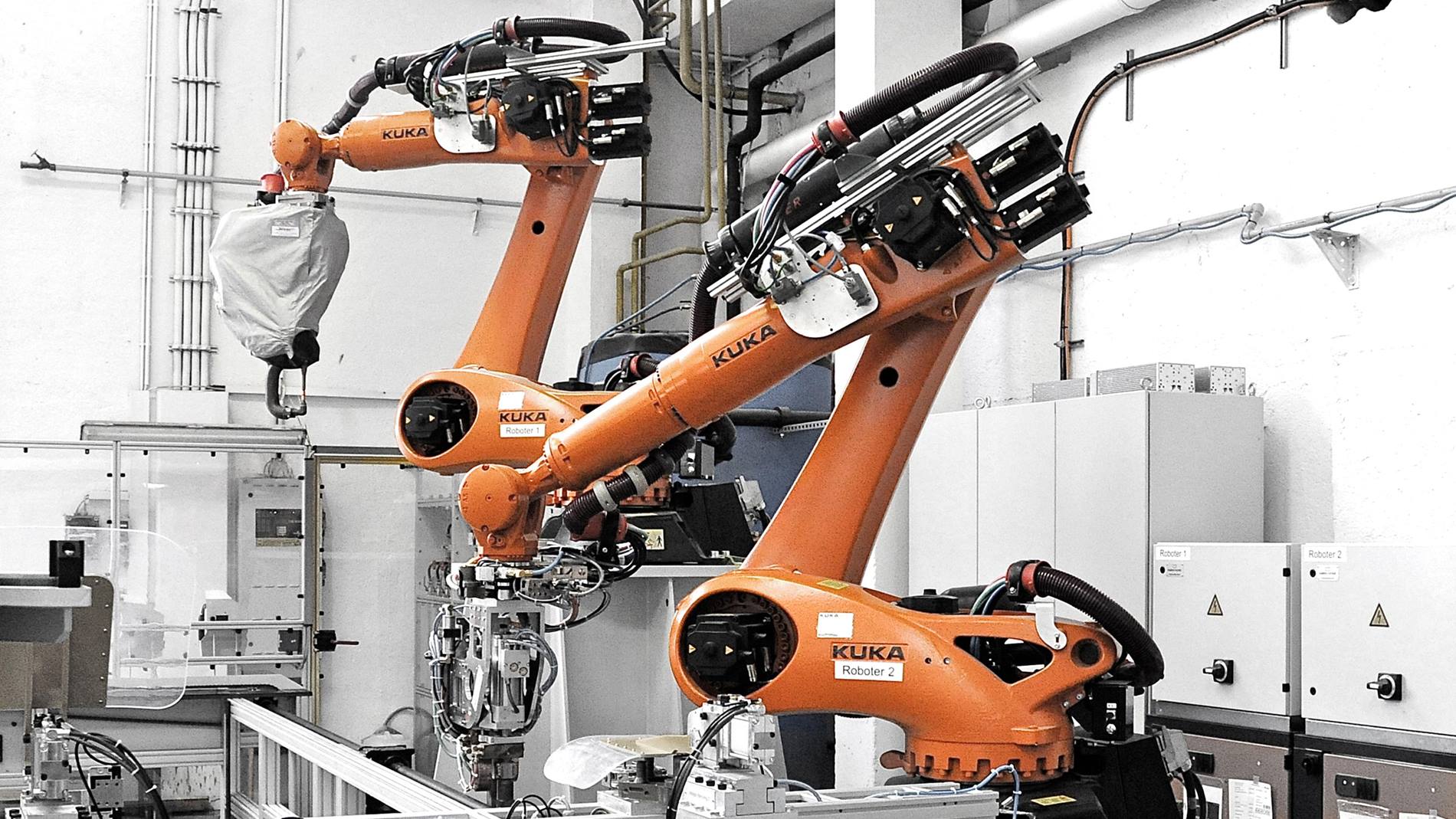

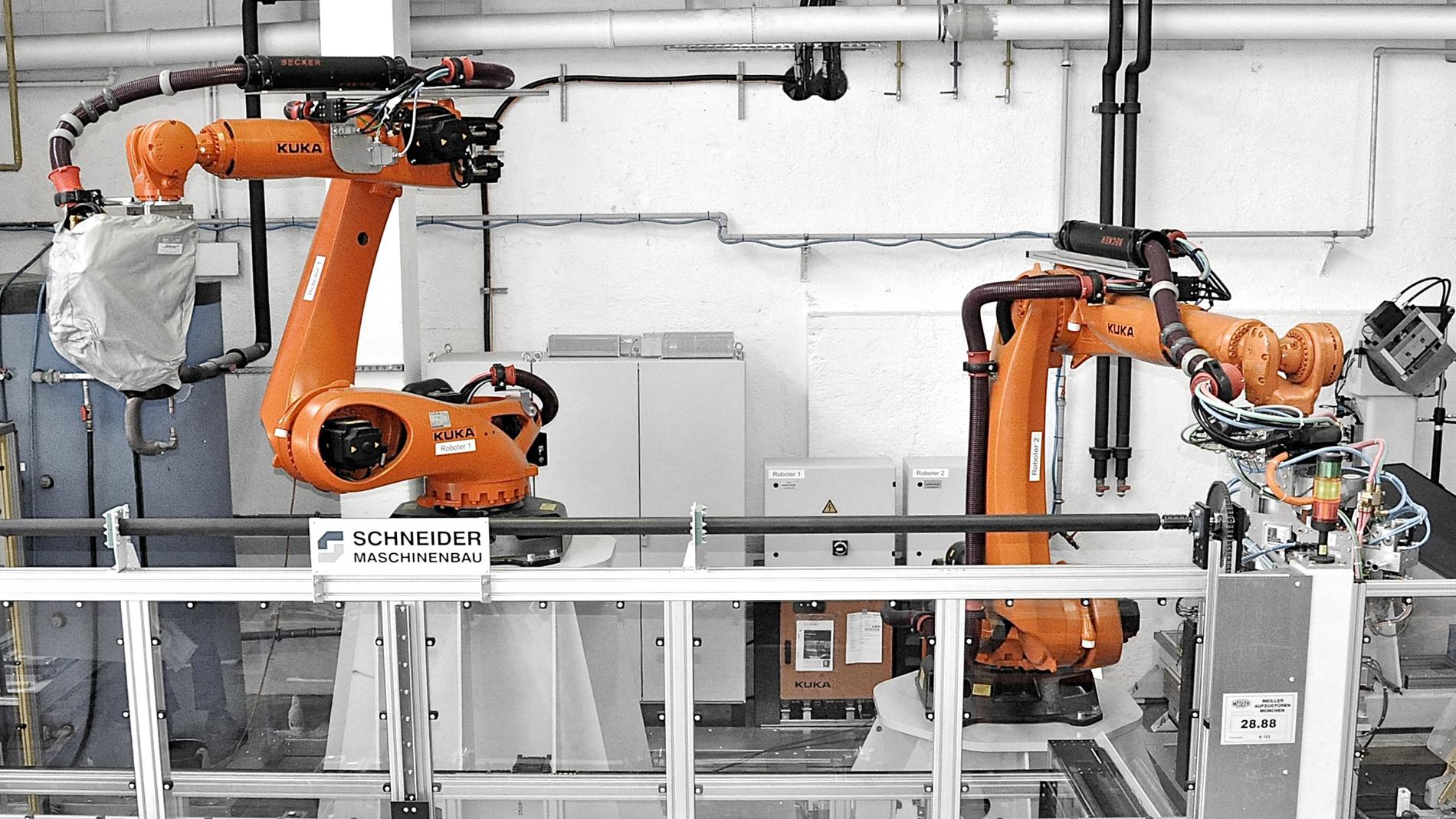

While the operator on one side of the changing table is busy loading and clamping, the other side is already getting down to business: in the first step, both KR QUANTECs make a start on the welds that are required. Robot 1, mounted on a pedestal for maximum reach and equipped with a special welding gun, carries out the projection welding. As a result, the KR QUANTEC can connect the top and bottom of the outer shell with the outer rail simultaneously. Robot 2, also pedestal-mounted, simultaneously spot-welds the open U-rail to the underside of the door panel.

This procedure takes less time than the projection welding, so while robot 1 is still welding, robot 2 quickly swaps over its welding gun for a vacuum gripper using an automatic tool change system from Stäubli Connectors, thereby mutating into a handling specialist. Once all the projection welds have been completed, robot 2 picks up the door panel and moves it to the stamping station where various rows of holes are punched into it. Following stamping, the robot moves the door panel to a press which lightly compresses the projecting sheets of metal in one corner, in order to rule out the potential of injury.

The robot's job ends when the door panel is placed on a pallet, at which stage the panel is ready to install without requiring further reworking. In order to cope with the limitless variety in terms of production engineering, Meiller Aufzugtüren makes consistent use of machining programs with parameter settings. When the system starts, the operator merely selects the material – stainless steel, galvanized steel or hot-dip galvanized steel – as well as the length and width of the door panel. The situation with the robot controller is quite different. The KR C4 not only calculates the robot movements including monitoring for collisions, but also works out the parameters and position of every single spot weld, the number and position of the punching operations that are required as well as the position of the clamping fixtures.

KUKA KR QUANTEC with power and reach

Two KUKA QUANTEC robots of type KR 150 R 3300 prime K carry out all the requisite production stages: projection welding, spot welding, handling, stamping, forming and finally placing the ready-to install door panel. Handling such oversize door panels is no problem for the KR QUANTEC thanks to its carrying capacity of up to 150 kilograms with a reach of 3301 millimeters. The KUKA KR C4 robot controller impresses in this task with superior performance. The high-performance controller can take in its stride the enormous variety of programs and the resulting complexity of the control task. As a result, none of the parameters are stored in the PLC, but rather in the robot controller.

Maximum flexibility and quality

The new system not only achieves maximum flexibility, but is also able to set benchmarks with regard to the quality of production. The KR QUANTEC welding robots and the welding engineering that is used ensure perfect welds and a precisely defined energy input. The panels only become hand warm during welding. There is hardly any more thermal distortion, and deformation or rotational offset no longer occur.

More than 80,000 door panels leave the plant of Meiller Aufzugtüren in Munich every year – and the trend is rising. What makes this statistic special is that hardly any door panel is identical to another. Passenger and goods elevators are always tailor-made, customer-specific solutions that are precisely adapted to the technical requirements of the building they are in. Meiller delivers door panels in infinitely variable dimensions.

Ultra-small batch sizes and countless variants

Small to ultra-small batch sizes and an endless procession of different variants have to be dealt with. These factors call for production systems that can rise to the challenge of the requirements involved, without problems.

KR C4 copes with the limitless variety

While the operator on one side of the changing table is busy loading and clamping, the other side is already getting down to business: in the first step, both KR QUANTECs make a start on the welds that are required. Robot 1, mounted on a pedestal for maximum reach and equipped with a special welding gun, carries out the projection welding. As a result, the KR QUANTEC can connect the top and bottom of the outer shell with the outer rail simultaneously. Robot 2, also pedestal-mounted, simultaneously spot-welds the open U-rail to the underside of the door panel.

This procedure takes less time than the projection welding, so while robot 1 is still welding, robot 2 quickly swaps over its welding gun for a vacuum gripper using an automatic tool change system from Stäubli Connectors, thereby mutating into a handling specialist. Once all the projection welds have been completed, robot 2 picks up the door panel and moves it to the stamping station where various rows of holes are punched into it. Following stamping, the robot moves the door panel to a press which lightly compresses the projecting sheets of metal in one corner, in order to rule out the potential of injury.

The robot's job ends when the door panel is placed on a pallet, at which stage the panel is ready to install without requiring further reworking. In order to cope with the limitless variety in terms of production engineering, Meiller Aufzugtüren makes consistent use of machining programs with parameter settings. When the system starts, the operator merely selects the material – stainless steel, galvanized steel or hot-dip galvanized steel – as well as the length and width of the door panel. The situation with the robot controller is quite different. The KR C4 not only calculates the robot movements including monitoring for collisions, but also works out the parameters and position of every single spot weld, the number and position of the punching operations that are required as well as the position of the clamping fixtures.

KUKA KR QUANTEC with power and reach

Two KUKA QUANTEC robots of type KR 150 R 3300 prime K carry out all the requisite production stages: projection welding, spot welding, handling, stamping, forming and finally placing the ready-to install door panel. Handling such oversize door panels is no problem for the KR QUANTEC thanks to its carrying capacity of up to 150 kilograms with a reach of 3301 millimeters. The KUKA KR C4 robot controller impresses in this task with superior performance. The high-performance controller can take in its stride the enormous variety of programs and the resulting complexity of the control task. As a result, none of the parameters are stored in the PLC, but rather in the robot controller.

Maximum flexibility and quality

The new system not only achieves maximum flexibility, but is also able to set benchmarks with regard to the quality of production. The KR QUANTEC welding robots and the welding engineering that is used ensure perfect welds and a precisely defined energy input. The panels only become hand warm during welding. There is hardly any more thermal distortion, and deformation or rotational offset no longer occur.