The task: update on industry standard

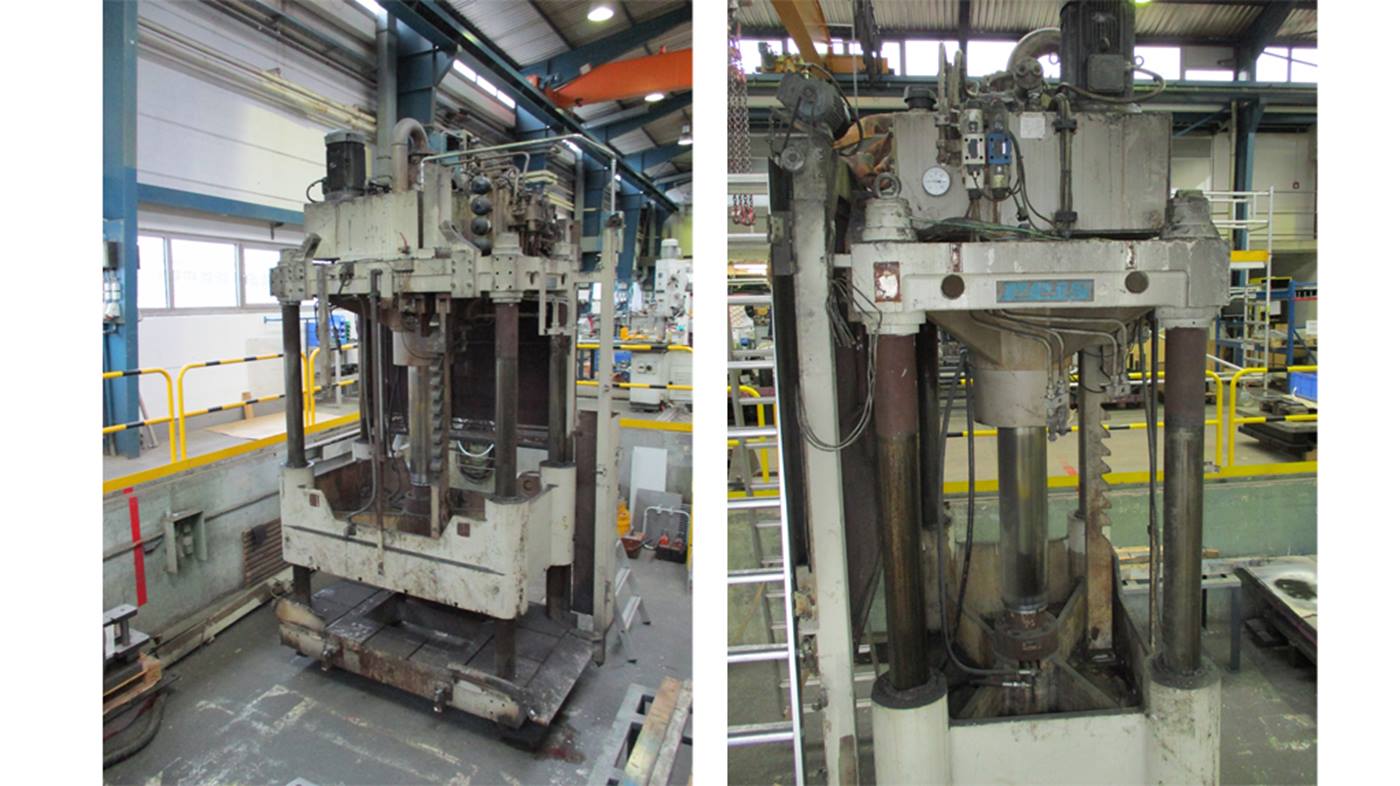

Before making the final decision, the customer once again called on the experts from KUKA, who had been there to advise on the original acquisition. After a rigorous evaluation of the mechanical, electrical, hydraulic and controller elements, the answer was clear: In this instance, investing in a general overhaul would be worth it. That is not always the case. “There are situations where – depending on the scope and level of the upgrade – an overhaul approaches the price of a new machine,” explains Eberhard Amrhein. “Nevertheless, certain parts remain old and it still costs about 80 or 90 percent of the new price tag to refurbish the machine. Depending on its size and functions, a new machine can also be built relatively quickly. You have to assess it case by case.”