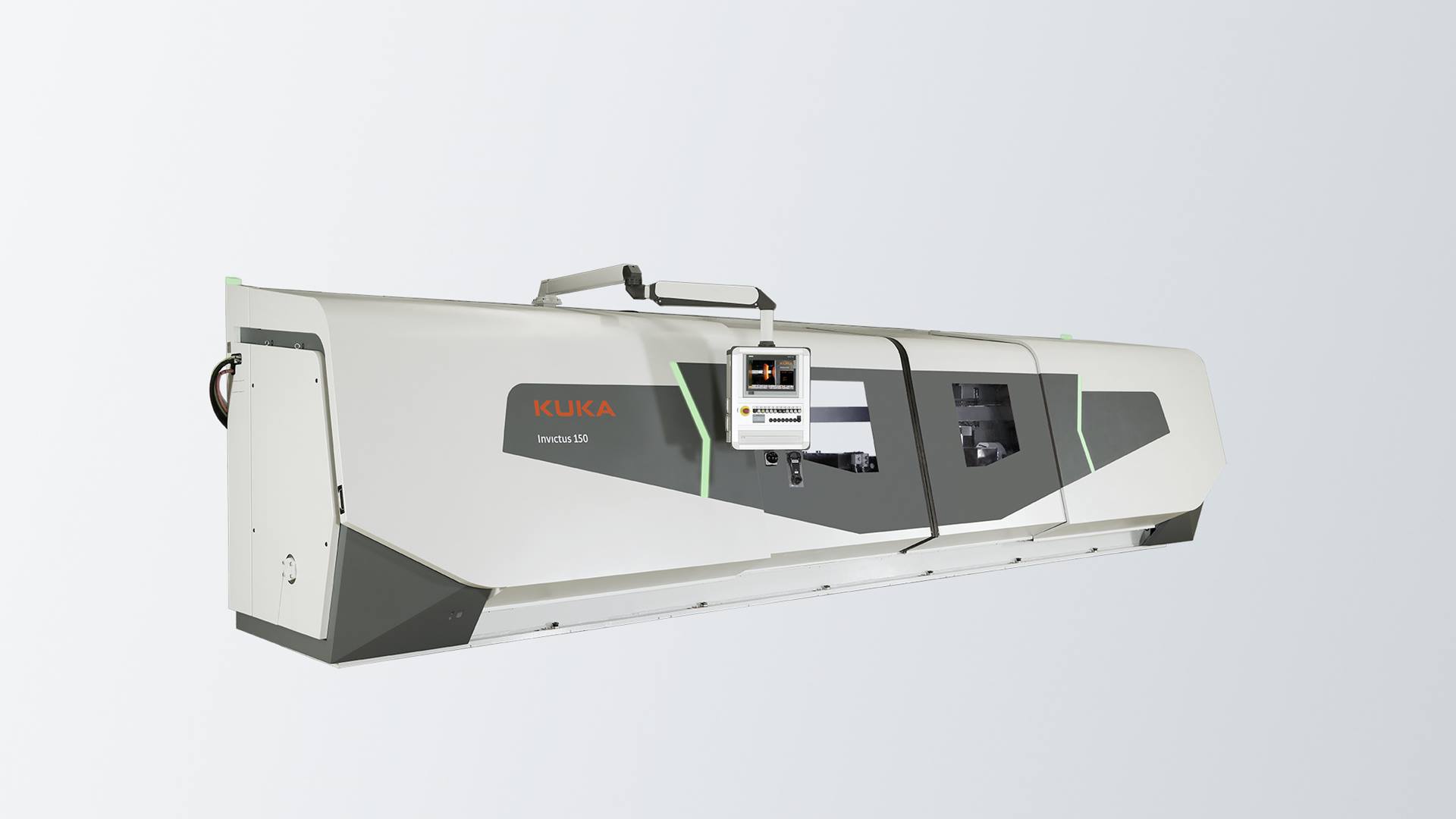

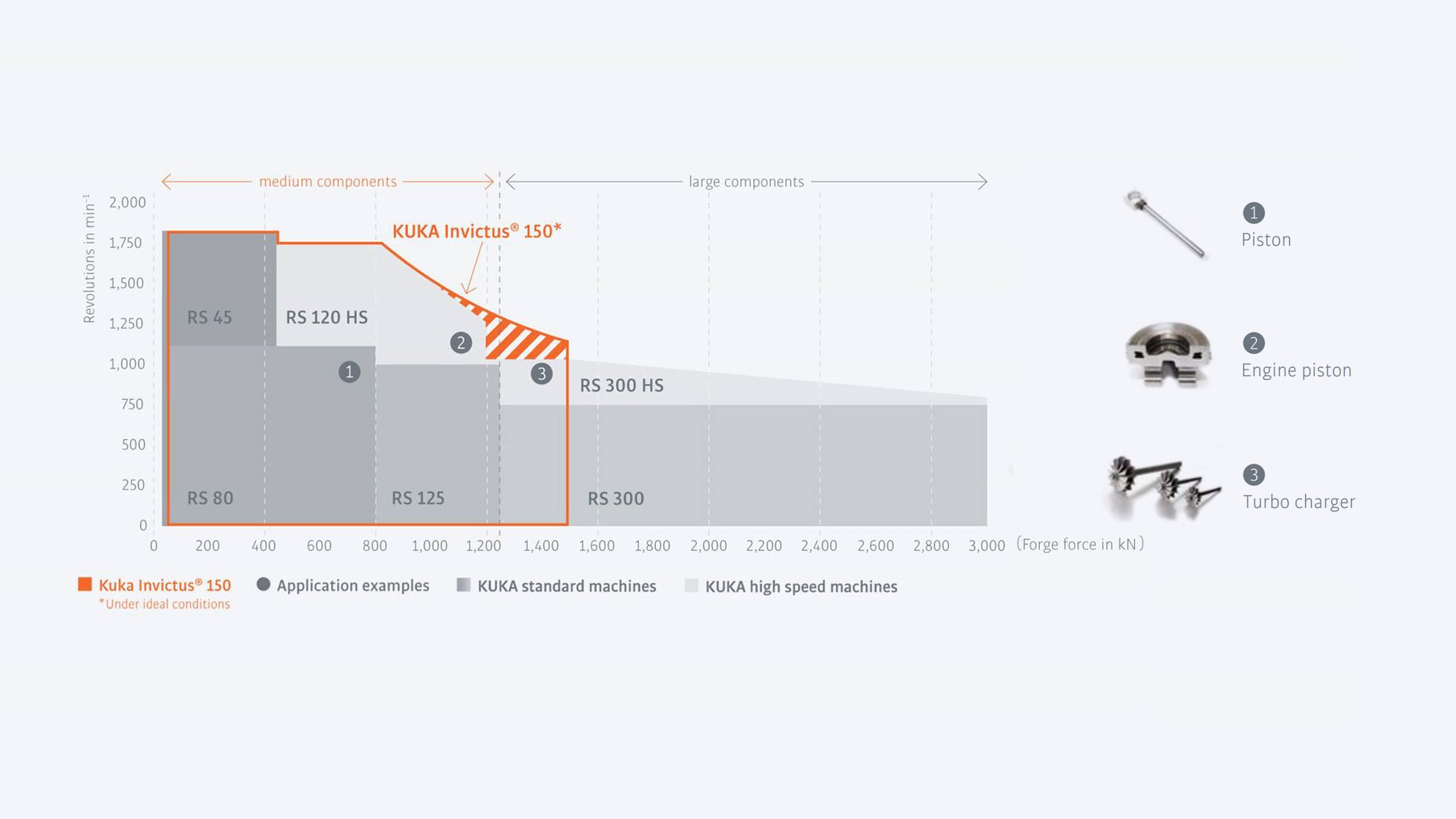

KUKA Invictus

强大、快速和精确:适合中大型工件的摩擦焊接机凭借高达 1500 kN 的顶锻力及其广泛的用途而备受青睐。

KUKA Genius in detail

-

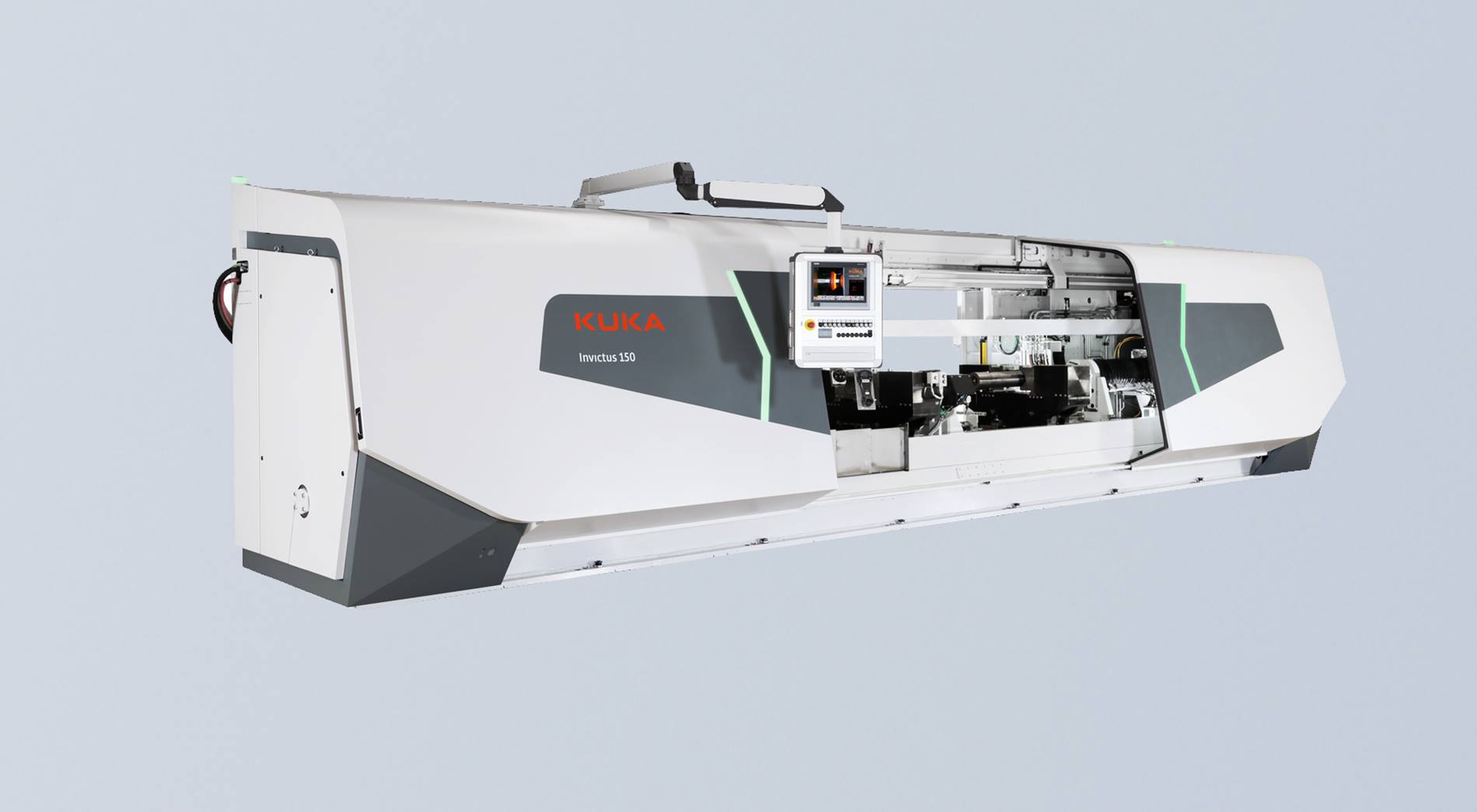

Generously dimensioned work doors

![]() Easy access - Generously dimensioned operator and maintenance doors enable optimal access from above and at the front of the machine.

Easy access - Generously dimensioned operator and maintenance doors enable optimal access from above and at the front of the machine. -

Transport-optimized design

![]() Plug & Play - Integration of hydraulic and electrical equipment reduces the floor space requirement and simplifies transportation

Plug & Play - Integration of hydraulic and electrical equipment reduces the floor space requirement and simplifies transportation -

Variable doors

![]() Safety and ergonomics - The weight-optimized operator door of variable size makes extremely short cycle times possible. The user-friendly layout of the working area ensures optimal ergonomic operation.

Safety and ergonomics - The weight-optimized operator door of variable size makes extremely short cycle times possible. The user-friendly layout of the working area ensures optimal ergonomic operation. -

Integrated light curtain

![]() Short cycle times and utmost safety - Integrated light curtain for cycle time optimization with the highest safety level

Short cycle times and utmost safety - Integrated light curtain for cycle time optimization with the highest safety level -

Swarf removal

![]() Thanks to the optimized design, a fixture for swarf removal can now, for the first time, be optionally positioned on the side or rear of the machine.

Thanks to the optimized design, a fixture for swarf removal can now, for the first time, be optionally positioned on the side or rear of the machine.

With the KUKA Genius you can work with customers to configure the machine to their requirements using a multitude of technology modules – just as the prospective user’s component, production planning and manufacturing strategies require.