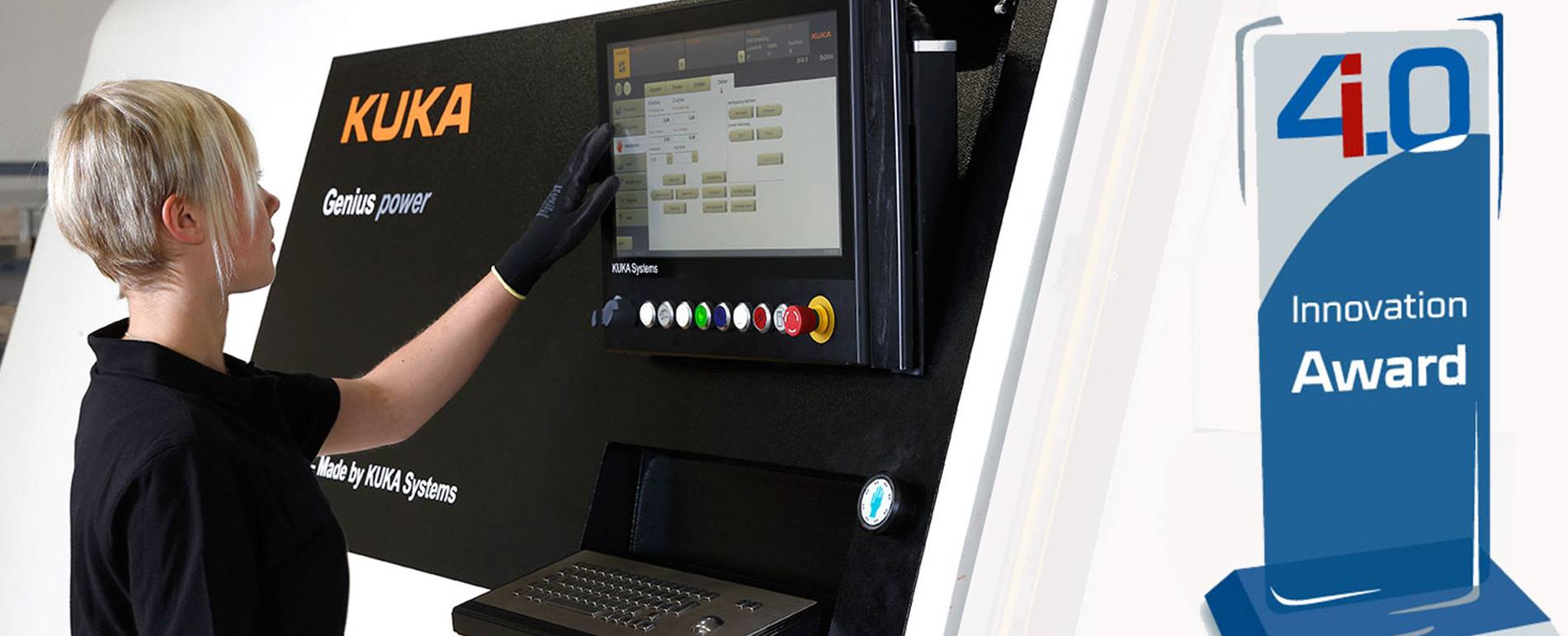

Vote for KUKA now in the Industrie 4.0 Innovation Award!

With the Industrie 4.0 solution KUKA SmartConnect.frictionwelding, the networked Genius friction welding machine learns to communicate in the cloud. For the jury of VDE VERLAG, this was worth a nomination for this year’s “Industrie 4.0 Innovation Award”. Now it’s over to the readers: they can cast their online vote for the KUKA solution as the best Industrie 4.0 product.

2017年9月20日

KUKA SmartConnect.frictionwelding

Into the cloud with KUKA SmartConnect.frictionwelding

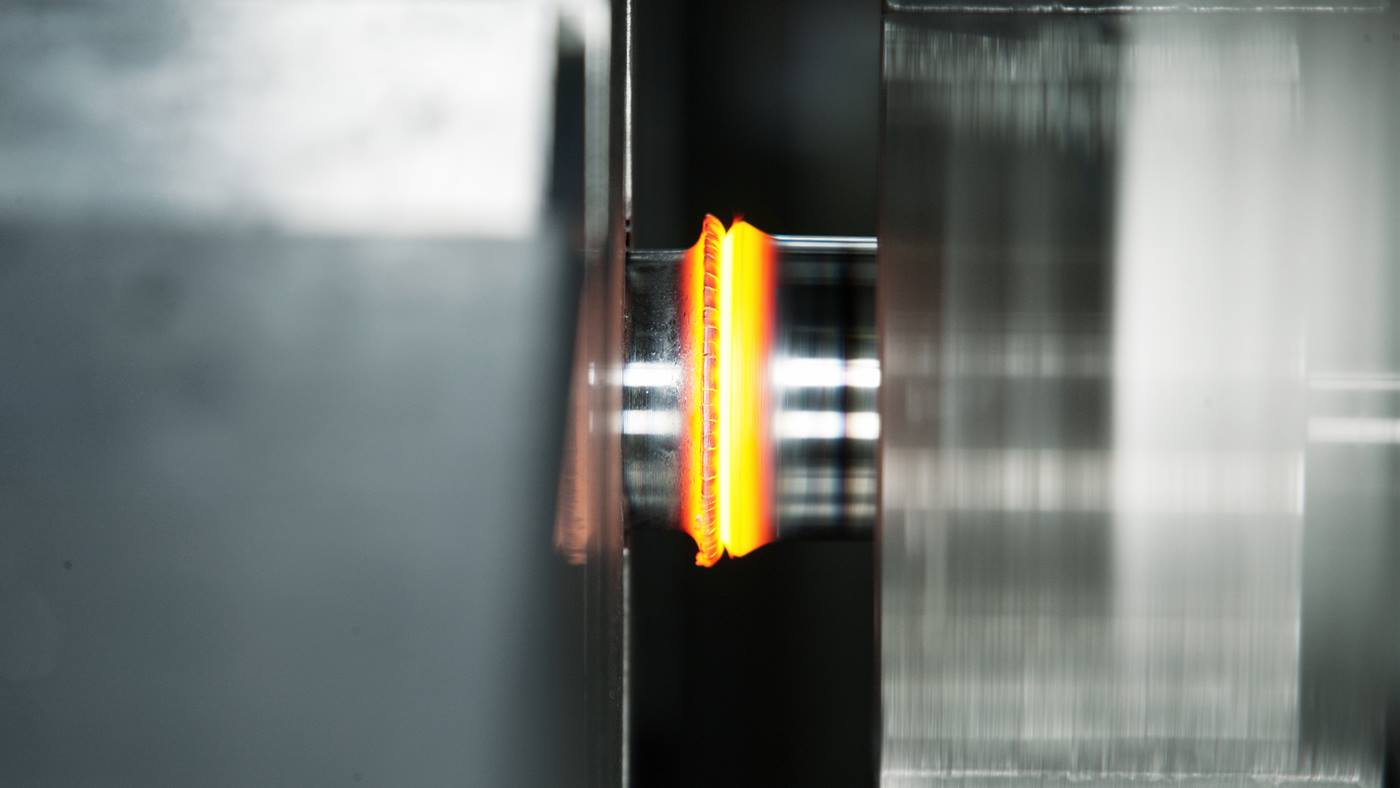

KUKA SmartConnect.frictionwelding is a cloud-based software application used by the Genius friction welding machine from KUKA Industries to integrate itself into KUKA SmartProduction alongside other cloud solutions already implemented by connyun. All machine, production and process data can be retrieved via a secure Internet connection and automatically analyzed – worldwide – via PC, laptop, tablet or smartphone. The friction welding machine communicates with the cloud via the Industrie 4.0 standard OPC UA and the KUKA Remote Service Client, a local edge gateway that handles the control functions and data communication with the cloud. In this way, important status data can be viewed from anywhere, welding processes can be monitored live, and problems can be detected and eliminated in good time.

“With the condition-based maintenance feature, the actual condition of machine components is factored into the calculation of maintenance intervals for the first time using sensor data. In this way, maintenance expenditure can be reduced by up to 75%. It is also possible to link and analyze important process variables with Expert Analytics and send messages, e.g. to the maintenance technician’s smartphone, for rapid troubleshooting. This all ultimately leads to increased uptime and even greater productivity of the friction welding machines,” says Product Manager Till Maier, summarizing the advantages.

KUKA solution among the ten best Industrie 4.0 products and innovations

It ensures that rationalization potential is leveraged and resources are saved. It is innovative. It also conforms to the reference architecture for Industrie 4.0 (RAMI 4.0).