Hemming: the technology

In hemming, the sheet-metal parts are bent in a forming process and then positively joined by welding or brazing. Firstly, the edge of the sheet metal is bent over. The component is stiffened and can subsequently be joined.

Hemming is also capable of joining different components. The automotive industry makes use of this benefit to make joints between sheet metal and plastic.

Automated hemming

The product and the process determine what the ideal hemming technique is. Depending on the component in question, there are two different hemming systems:

- Tabletop hemming is an automatic, electro-mechanical system for hemming a wide range of materials with a high level of process reliability. This technique is particularly suitable for high-volume production.

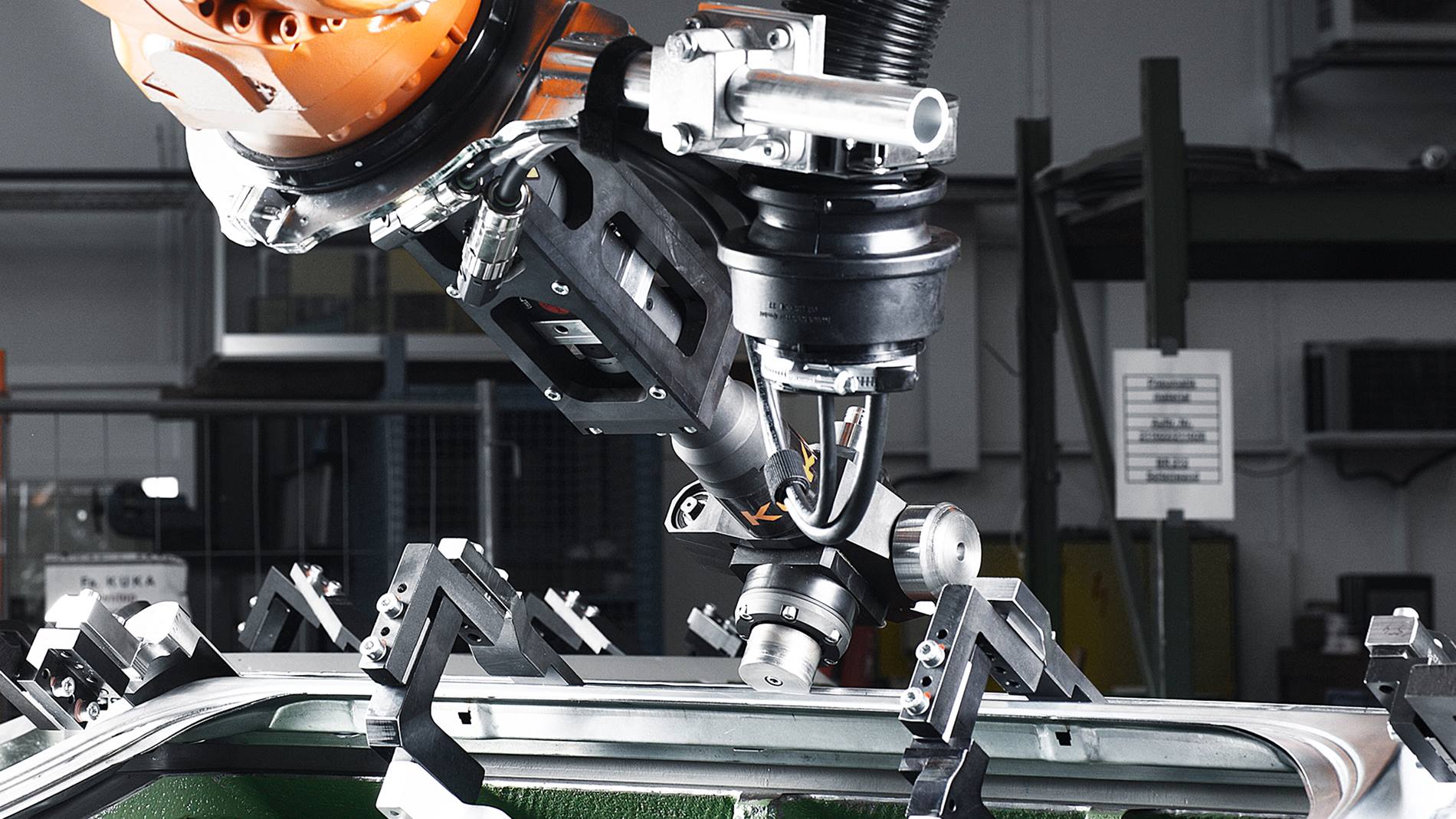

- In roller hemming, an industrial robot joins the components with the aid of a roller hemming head. The procedure stands out primarily for its flexibility. In line with the Industrie 4.0 philosophy, the robot can hem different components. By using a robot, it is possible to exchange the rollers or introduce a different technology quickly.

Furthermore, it is also feasible to use a hybrid solution incorporating both systems.

Hemming: the advantages

Hemming increases the strength of thin components. This technology also offers the following advantages:

- You can join a wide range of materials – from aluminum and steel right through to plastics

- You achieve shorter cycle times: The motion of the flange-mounted hemming roller is closely synchronized with the robot motion over the component. As a result, it is possible to cut production time by 50 percent.

- As the hemming process can be executed precisely, you will increase product quality.

We work with you to ensure that the ideal hemming solution is used in your production process. Give us a call and we can discuss your specific production requirements.