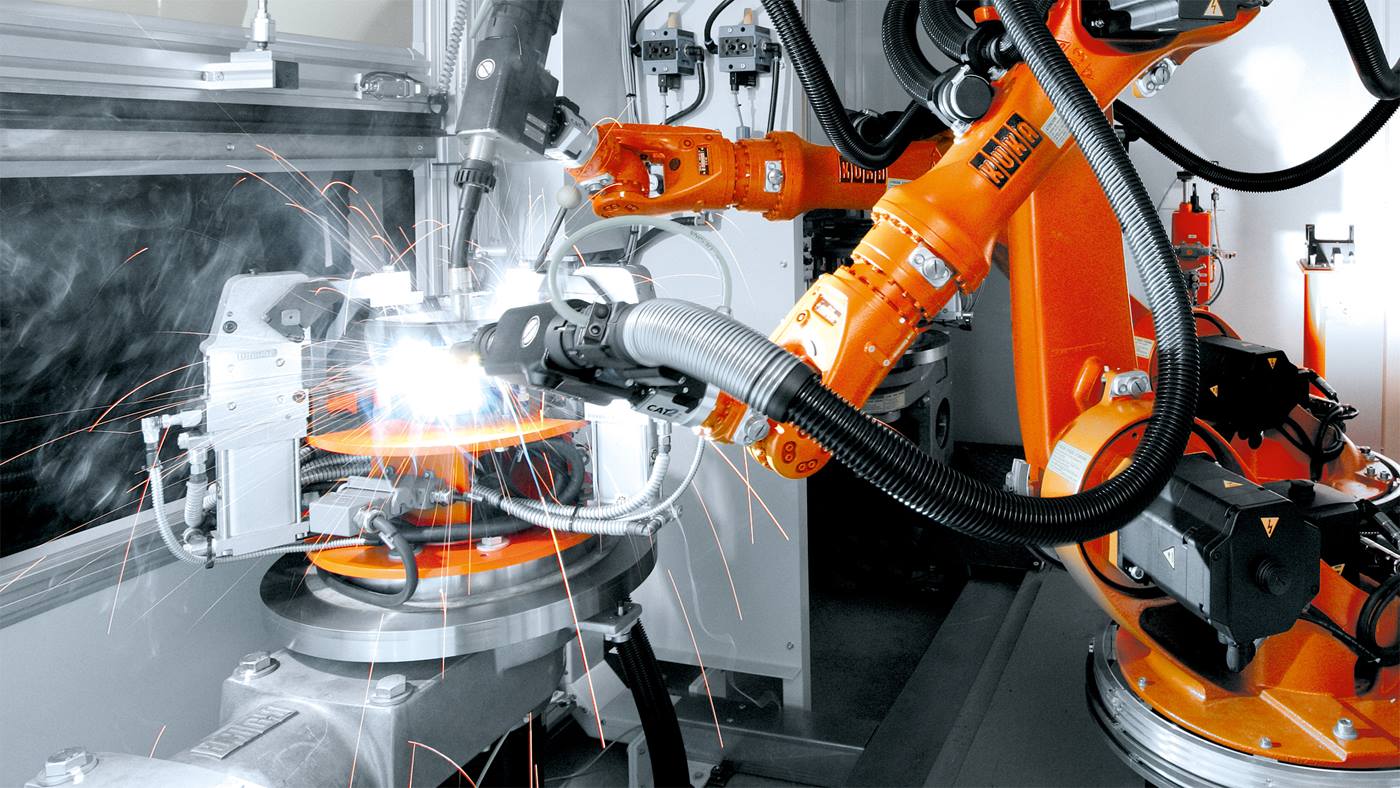

Laser hybrid welding: the technology

The perfect combination: laser hybrid welding combines the advantages of laser welding with those of arc welding.

In this welding process, an advancing laser beam initially heats the surface of the workpiece to vaporization point. This results in deep and narrow penetration. The subsequent arc forms a wide focal spot.

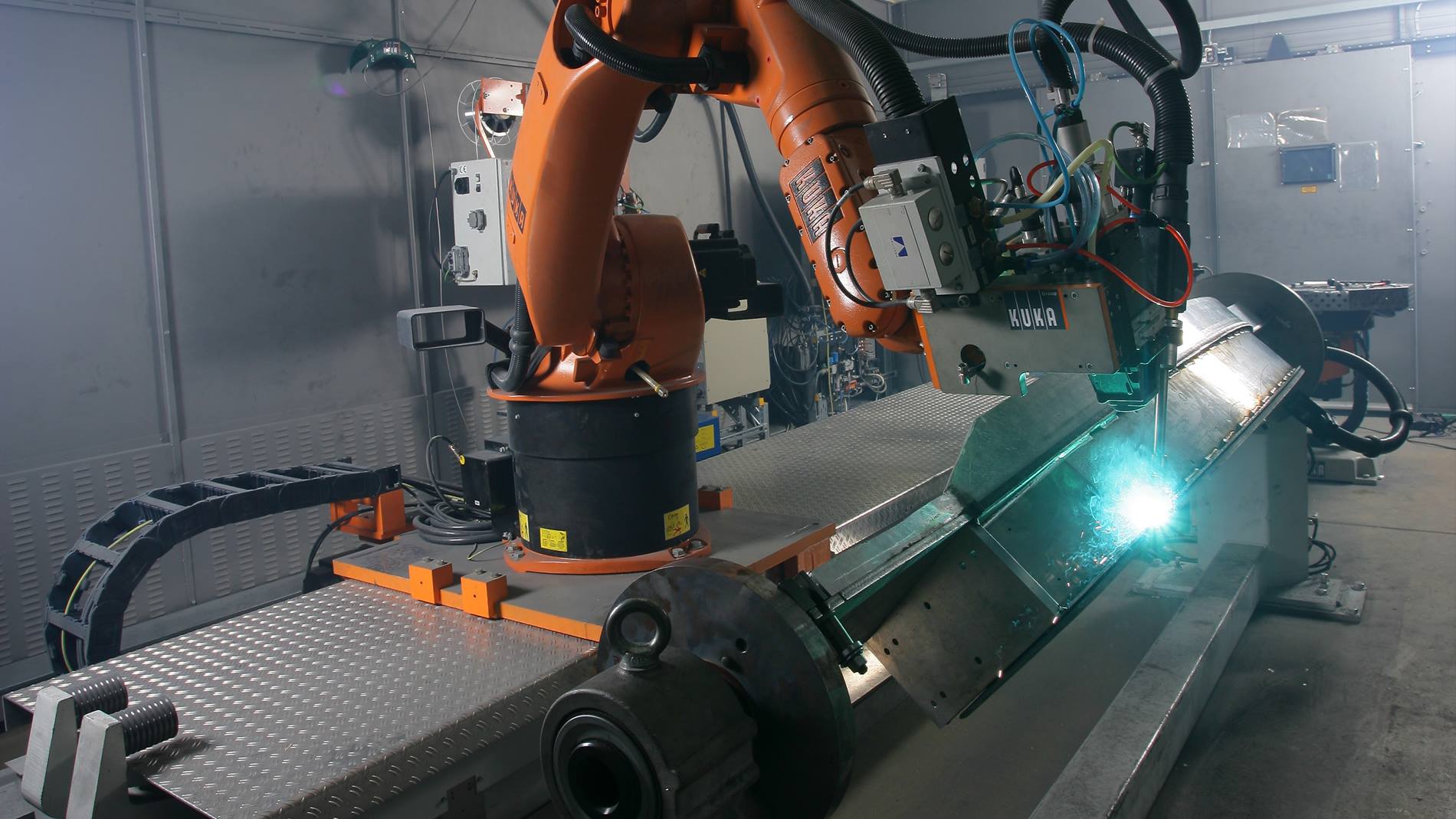

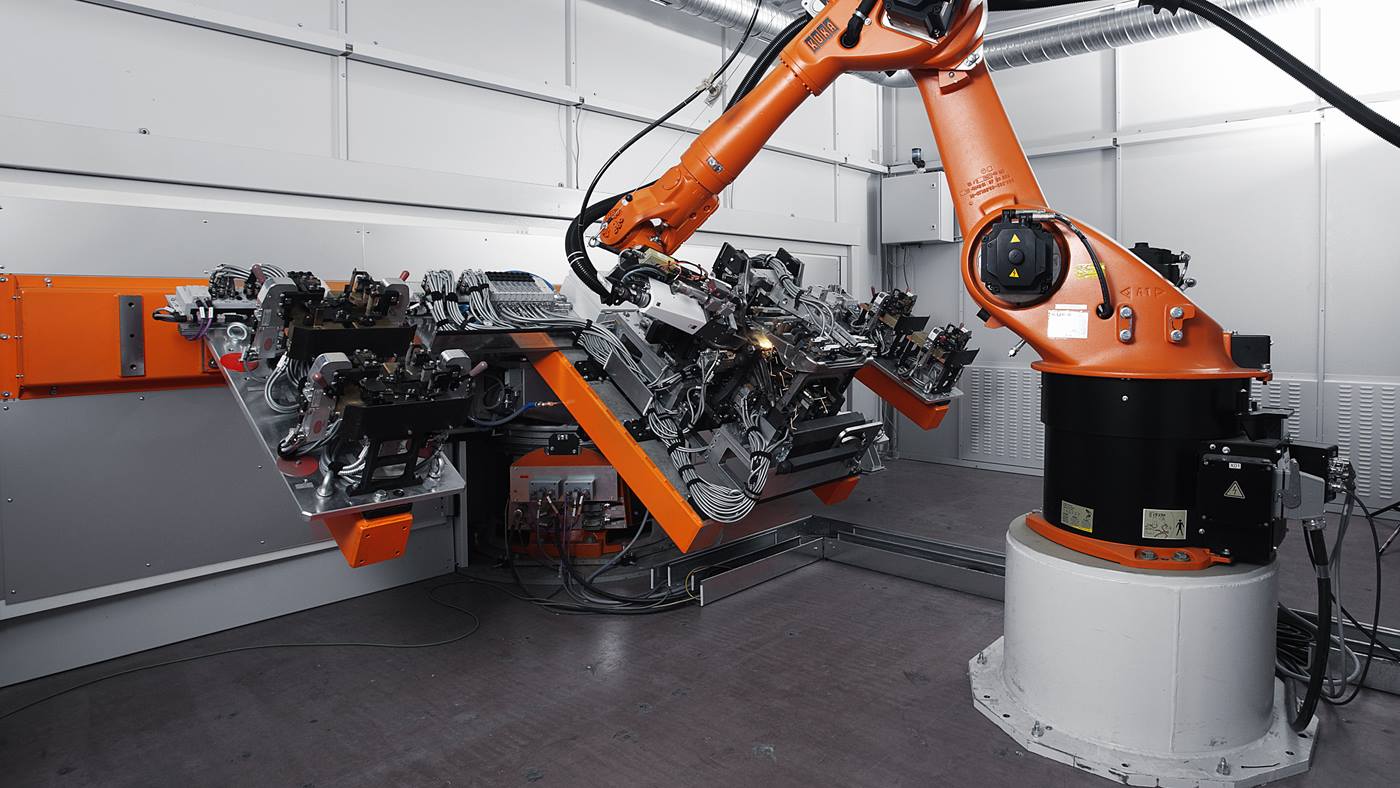

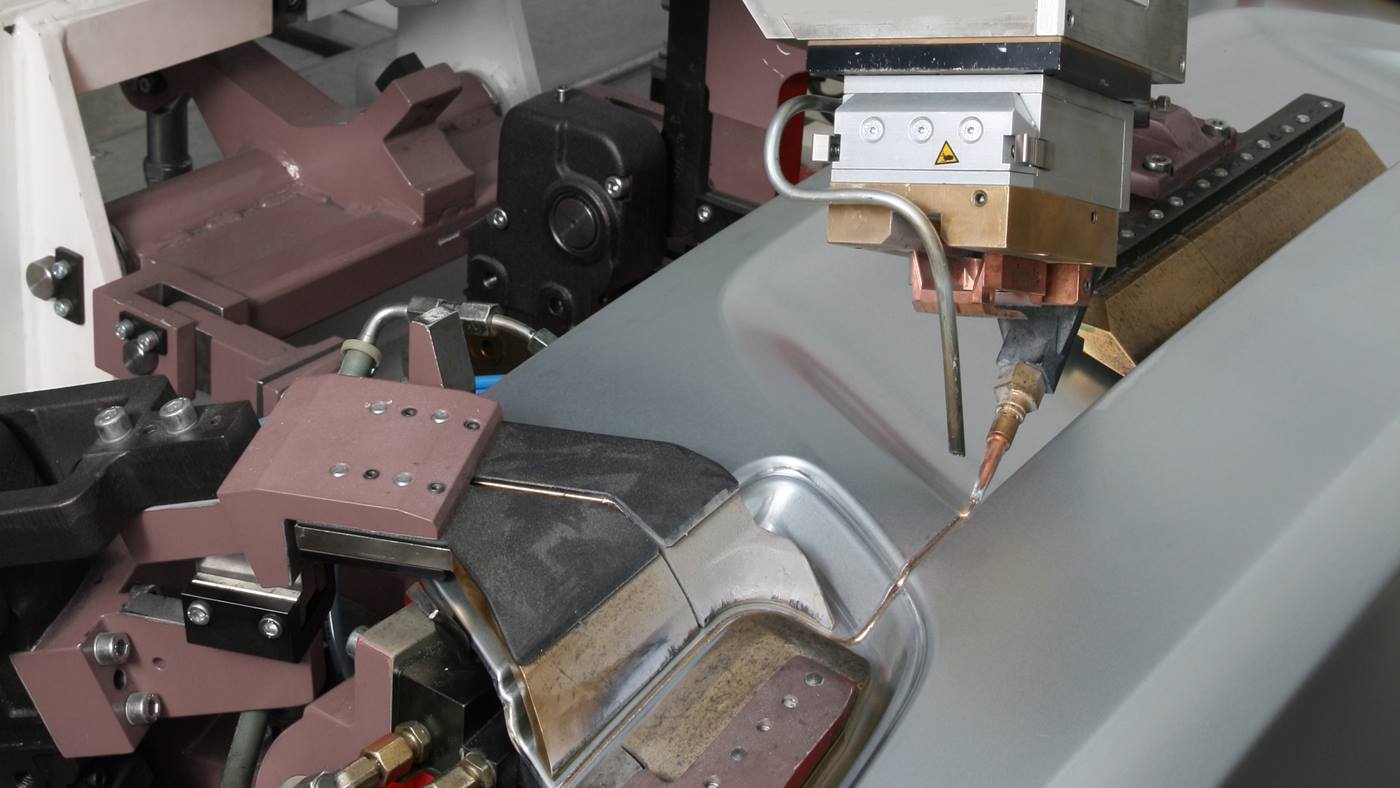

Automated laser hybrid welding

You have a thick-walled component and wish to automate your production? If so, laser hybrid welding with the KUKA KS HybridTec end effector is the perfect choice. The innovative design enables optimal adaptation to the specific application – particularly due to its high flexibility and the integrated sensors.

Laser hybrid welding: the advantages

By combining the advantages, the hybrid technology avoids the disadvantages that the individual processes entail. Laser hybrid welding offers you:

- Higher welding speeds

- Improved seam quality

- More stable processes

- Lower thermal distortion or the component

Give us a call and benefit from the advantages of the combined process for your production operations. We are happy to advise you.