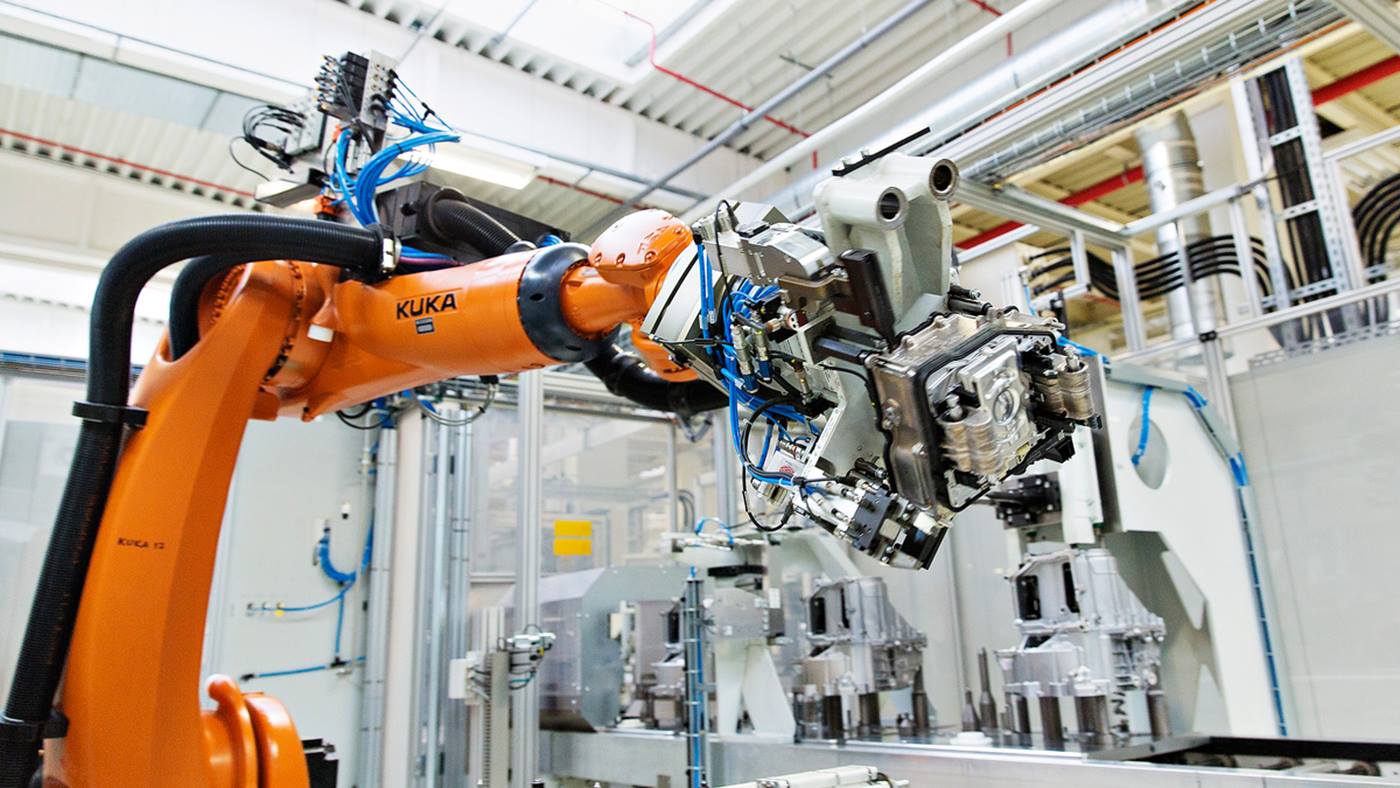

Application and robot programming

With the aid of our support services, applications and robots can be programmed without interruptions in production. We support you in preparing for product changeovers and commissioning offline as well as responding quickly and flexibly to changes in the production process.

Advice during the design phase

Benefit from the many years of wide-ranging experience of our application specialists when designing your production system and avoid planning errors at an early stage.

Feasibility study

Our experienced application specialists can evaluate in advance how you can implement your ideas perfectly with the help of our products.

Standardization

A uniform and structured robot program structure lowers maintenance costs and reduces downtimes during troubleshooting. Program adaptations or extensions can be carried out more quickly. We offer you ready-made program modules and flexible control concepts for robotics. We also supply the appropriate SPS interface.

Simulation and offline programming

The ideal combination for cycle time-optimized implementation of your application. Simulation is used to determine the optimum motion paths and pick-up points. The results are used in offline programming to ensure fast and cost-efficient implementation of the application on your system.

Safety Services

Safety is increasingly being realized via software products. We advise you on the design of your safety concept and subsequently on the configuration of the KUKA.SafeOperation technology packages. We can also offer you individual workshops on the Machinery Directive.

KRL (KUKA Robot Language) and Sunrise programming

We create the complete robot programming for your production system - be it for KUKA robots with KR C4 or the LBR iiwa with Sunrise controller. We work closely with you to optimize the process flow and support you in integrating robotics into your production system.

SPS programming

Our range of services also includes programming your system control via the Totally Integrated Portal (TIA Portal) from Siemens. In this way, robots are integrated into your plant control system in the shortest possible time.

Support with robot programming

Do you need temporary support with programming your application? Would you like to expand your existing range of components? Our specialists will convert your specifications into structured and logical robot programs. Depending on your requirements, you can request us on a daily or weekly basis.

Configuration of KUKA.SafeOperation

We configure the KUKA.SafeOperation technology packages according to your specifications. We then check and document the configuration, starting with the cell area, work and safety areas, through to the various tools and reduced speeds. On request, we can test the spatial limits including the robot's overtravel paths.

Function extension

Would you like to expand your production process with new functions? Would you like to adapt the communication signals to the robot because your new processing machine offers more possibilities?

Function expansions are another element in our range of services so that you can adapt your existing system to new requirements.

Function expansions are another element in our range of services so that you can adapt your existing system to new requirements.

Individual workshops

We offer tailor-made workshops on the topics of programming, program standardization, machine safety and SafeOperation. The workshops can be held either at KUKA or at your premises. The focus of the workshop is based on your individual requirements.

Retrofit

Would you like to modernize your production system and replace your existing robot with an up-to-date and modern product? We will be happy to support you in the replacement process with a service package tailored to your requirements. Starting with the removal and installation of the robots, through adaptation designs and program conversion, to commissioning, start-up support and instruction of your system operators.