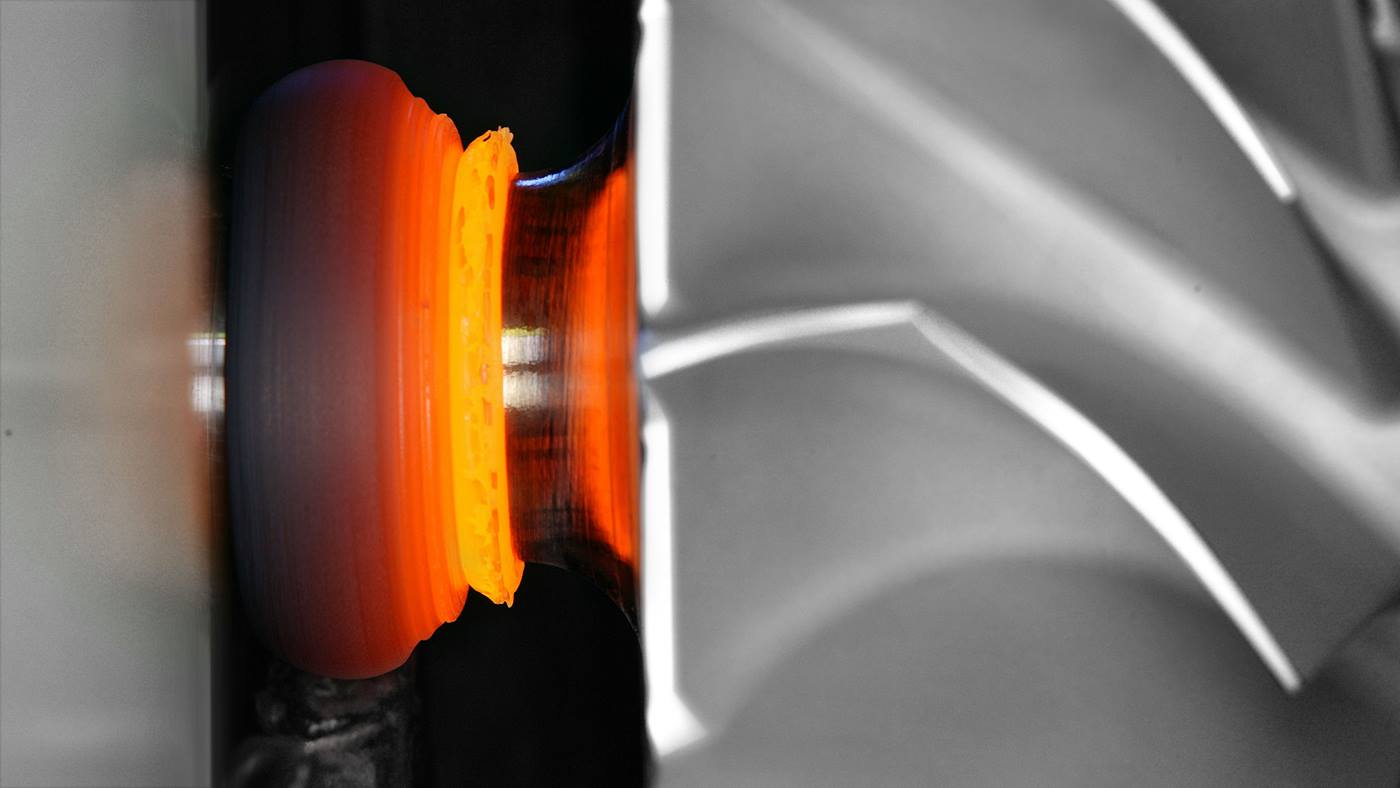

Contract welding to high industrial standard

With more than 50 years of experience in

rotary friction welding and two certified friction welding centers in Augsburg (Germany and Halesowen (UK), KUKA has a large and diverse machine pool with a working range of 2-300 t (forge force 20-3000 kN) for the welding of cross-sections from 10 to 30,000 square millimeters (steel).

Our company is supported by an in-house metallurgical laboratory, heat treatment capabilities before and after welding as well as solutions for preparing parts for the welding process. We carry out the friction welding of metallic materials in accordance with DIN EN ISO 15620:2019.

Contract manufacturing of individualized components in any size, including bimetallic material combinations

The possibilities of friction welding cover many steel materials and a wide range of material combinations, including the joining of parts of the same or different materials. Possible combinations include copper and aluminum, copper and stainless steel, aluminum and stainless steel, structural steel and stainless steel, titanium and aluminum, nickel alloys and titanium, and many more. Besides this, there is a selection of geometries such as rod to rod, tube to rod, rod to plate, tube to plate and tube to tube. The KUKA and Thompson rotary friction welding machines make this diverse range of material combinations possible, ensuring successful metalworking for a wide variety of applications and industries.

Additional services in the area of rotational welding

- Machining – Machining processes required before or after friction welding

- Removal of welding flash – With certain machines and applications, the resulting welding flash can be removed automatically.

- Heat treatment – Before and after welding

- Pre-washing – Pre-washing of certain components in our industrial cleaning machine in order to remove grease/oils and other possible impurities (Halesowen site).