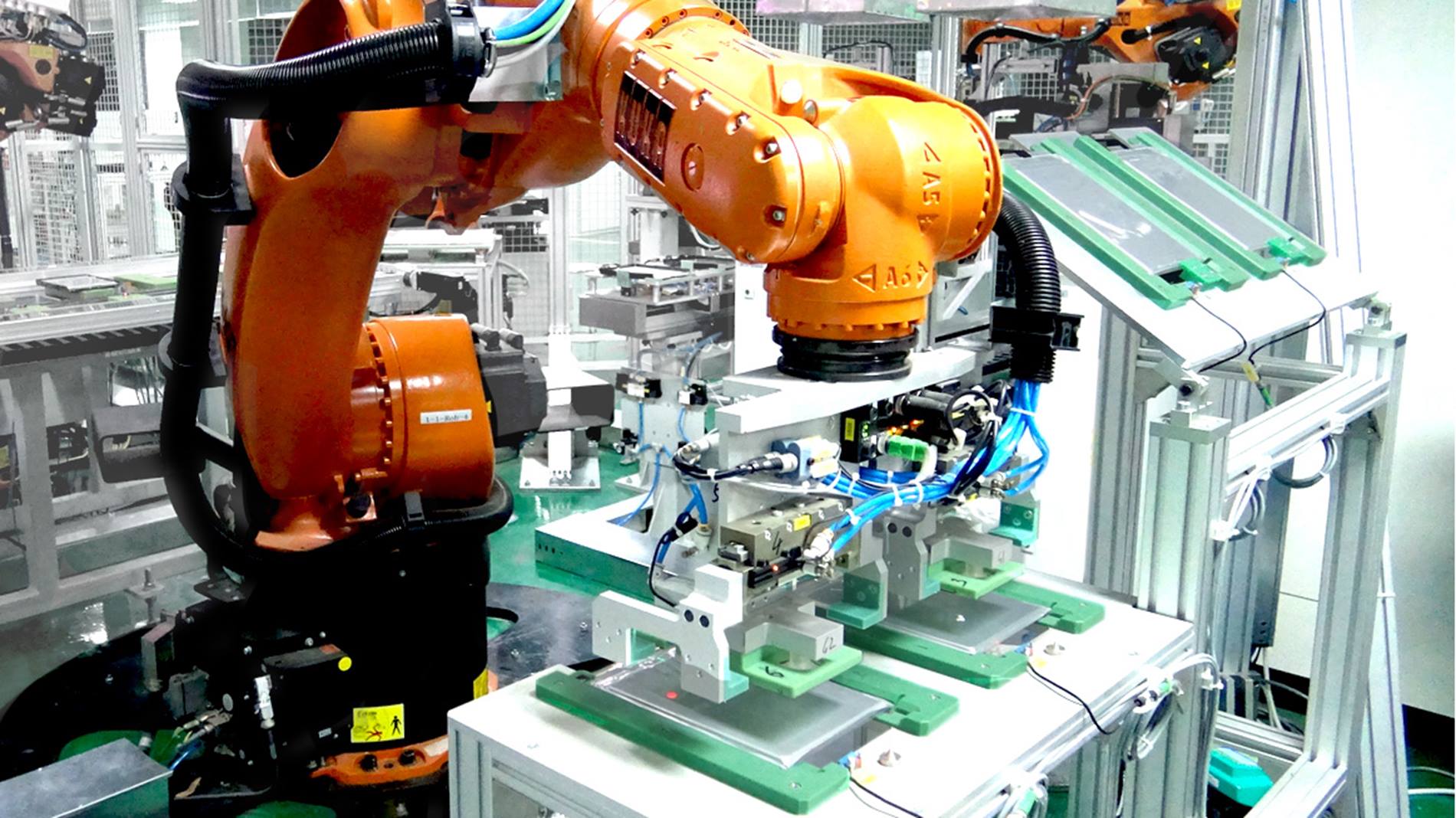

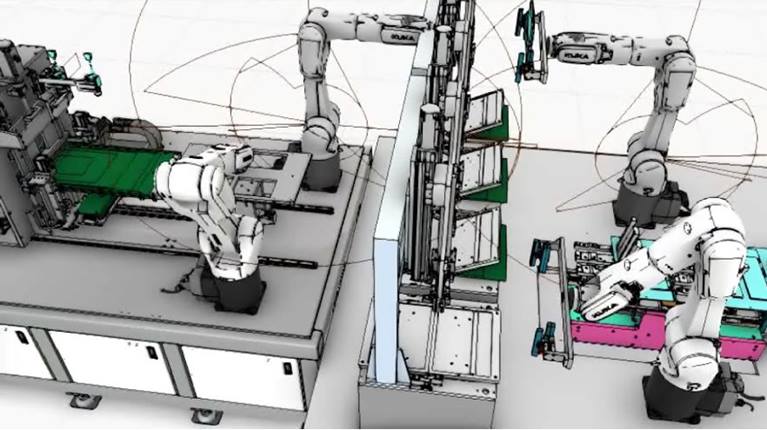

KUKA as an innovative automation partner for the production of all kinds of lithium-ion battery cells

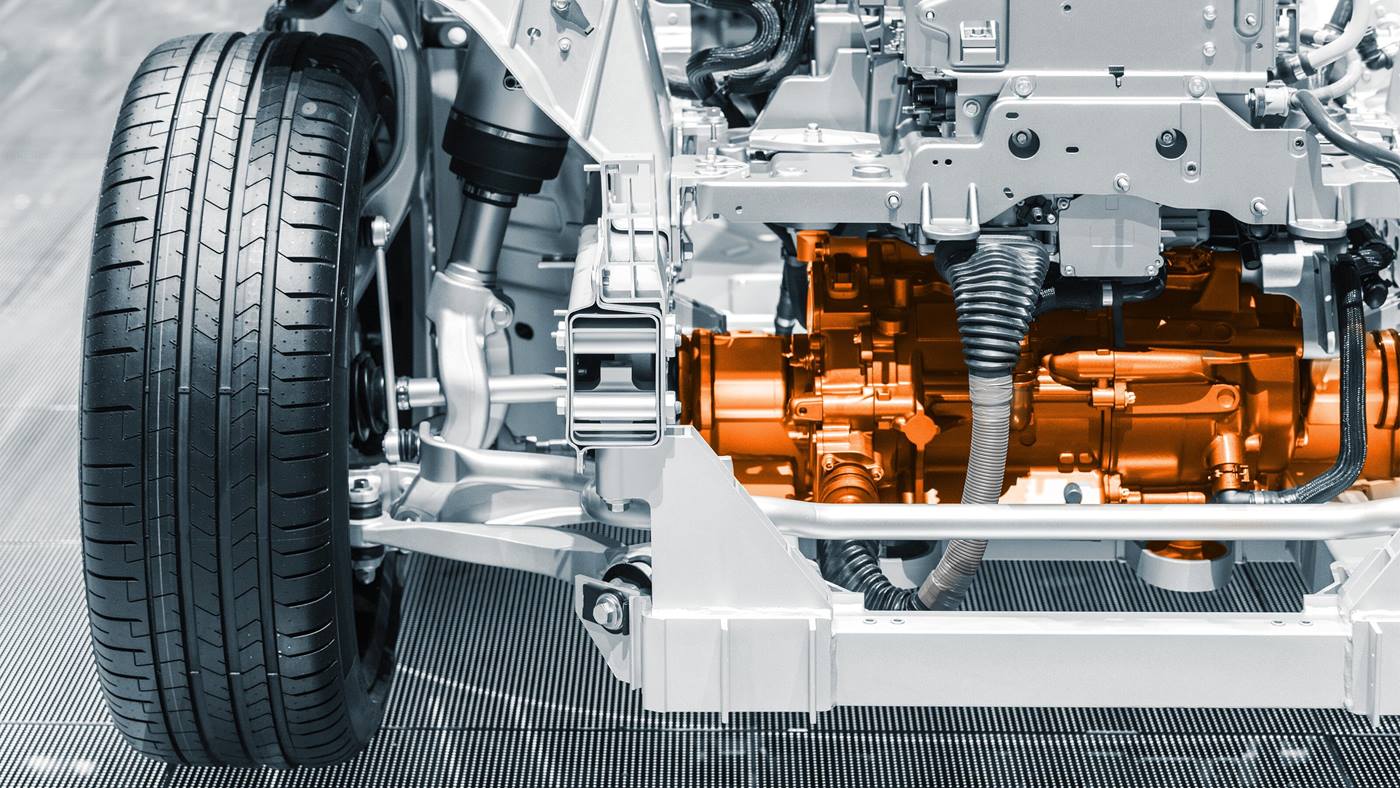

From electromobility to entertainment electronics

The use of lithium-ion batteries has become increasingly important due to their high energy density. Demand is continuously increasing, which can pose challenges for your company. KUKA offers you support as a reliable and experienced partner with certified and specific products as well as customized services – in Europe, the U.S., China and anywhere else around the globe. Thanks to our technological knowledge and innovative robotics, we meet all requirements of electric car manufacturers and producers of portable electronics.