What is the technology behind the soldering process?

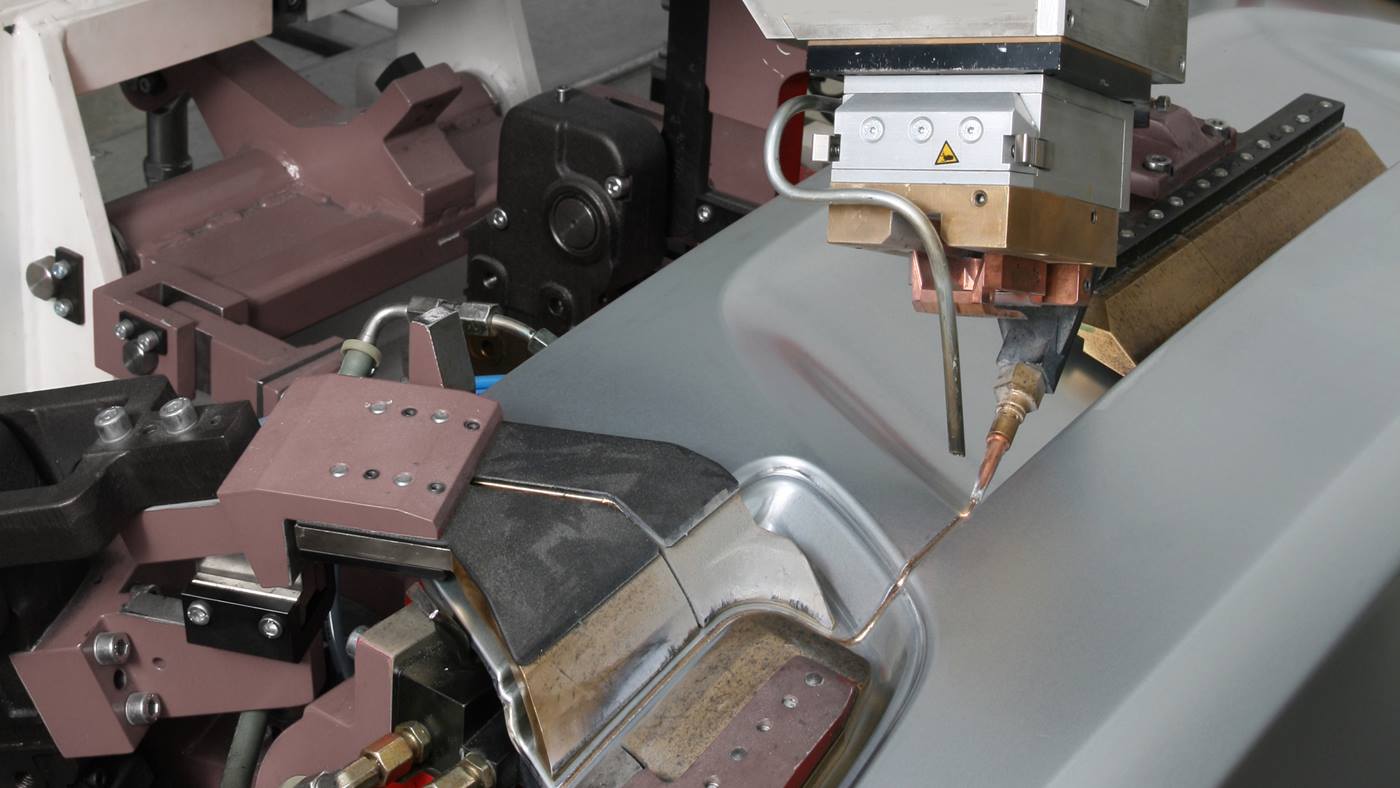

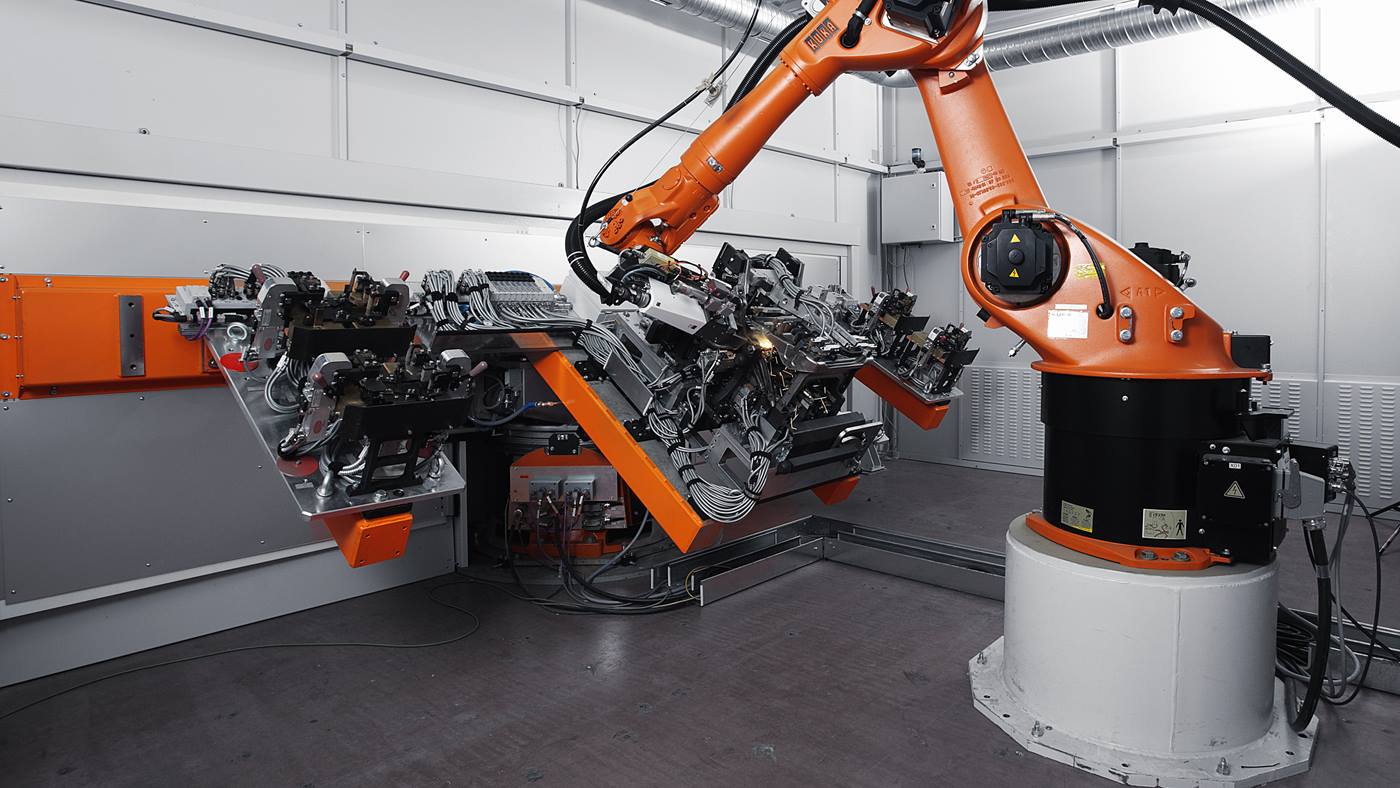

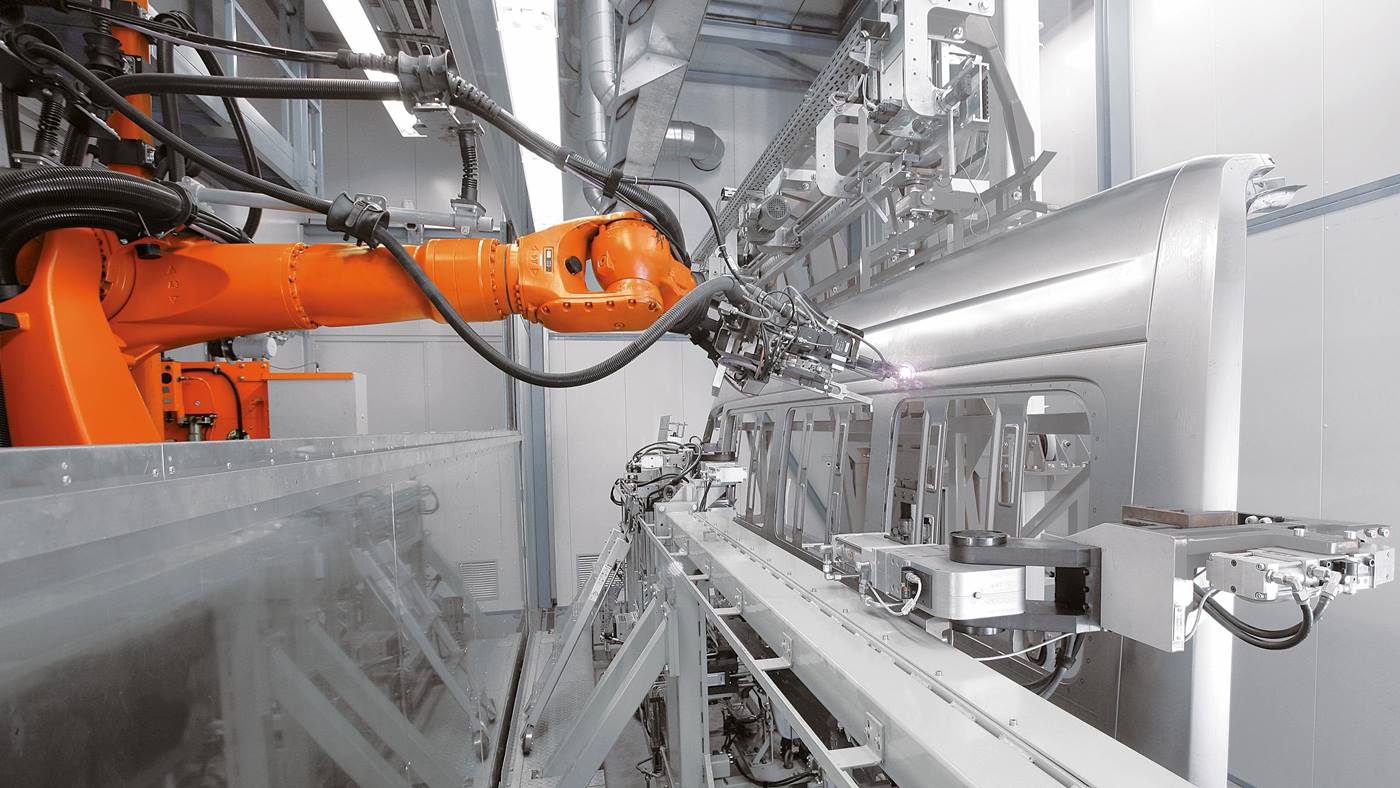

Soldering is a thermal process for the bonded joining of materials. With the help of a soldering iron or laser, the required heat is provided for solid soldered joints and for melting the solder. This allows various components and materials – such as those made of nickel, copper, metal, steel, iron and aluminum – to be bonded together. A metal alloy that melts easily (called the solder) serves as the bonding material for the soldered joint. Soldering process equipment includes an automatic, programmable solder feeder and a variety of sensors for process monitoring. One special application is soldering in a vacuum or shielding gas. These processes are used to ensure that stringent cleanliness requirements are met, e.g. for semiconductor assembly or in the production of high vacuum systems or electron tubes.

Distinction between two different soldering technologies:

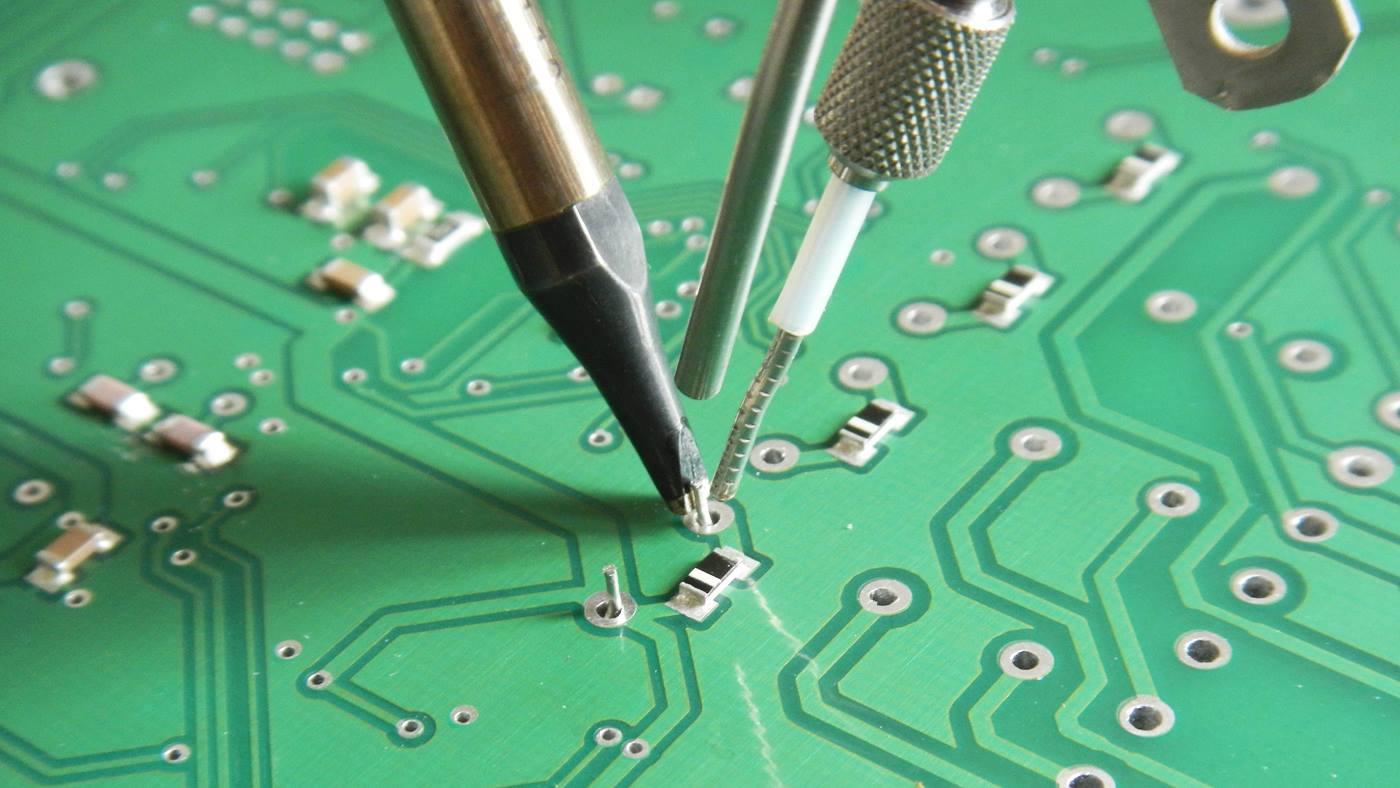

- In soft-soldering, the melting point of the solder is below a temperature of 450 °C – for example, in the electronics industry.

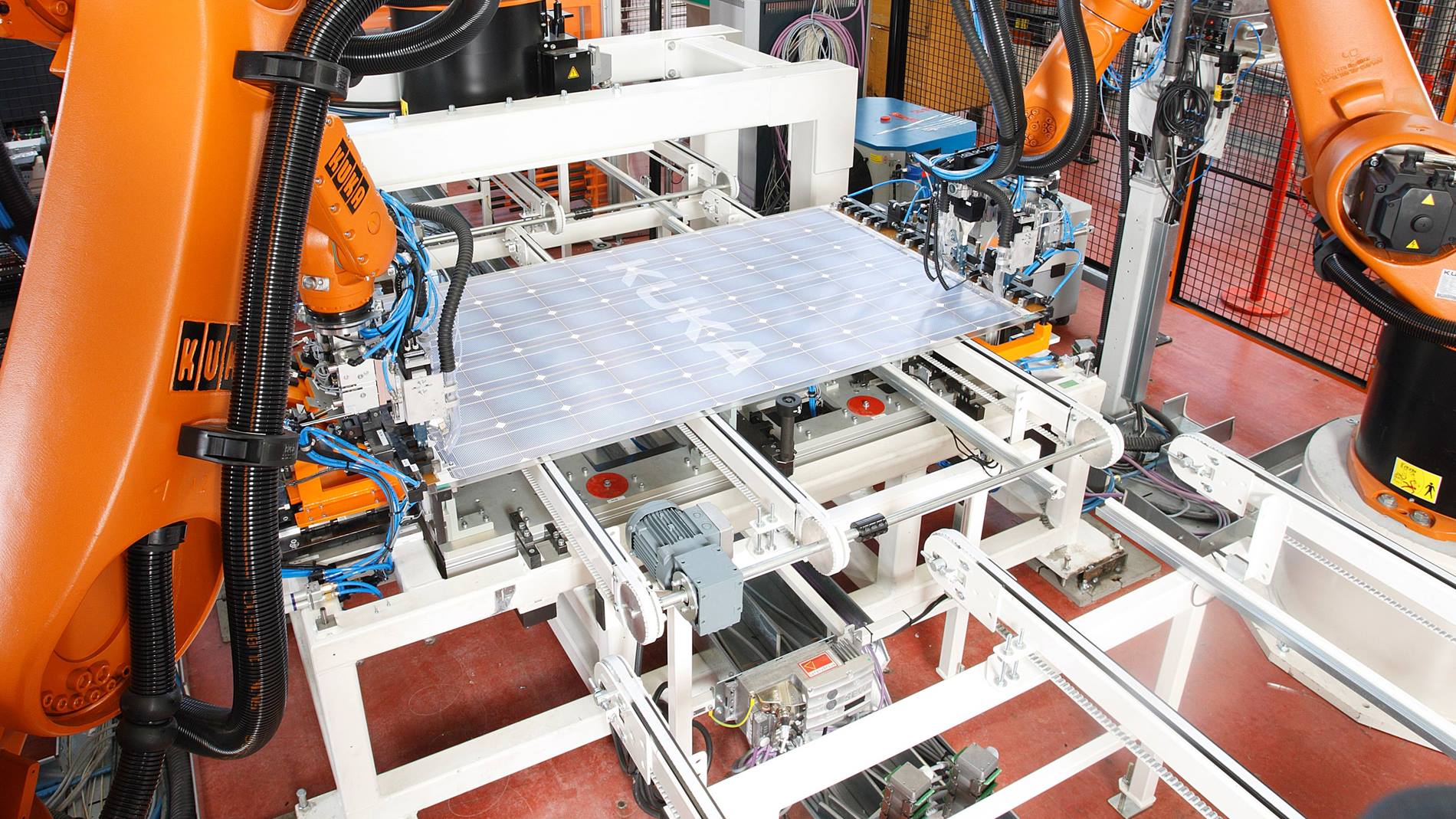

- In hard-soldering, or brazing, the melting point of the solder is above a temperature of 450 °C – for example, for particularly strong joints in the automotive industry or in the photovoltaic and battery sectors.