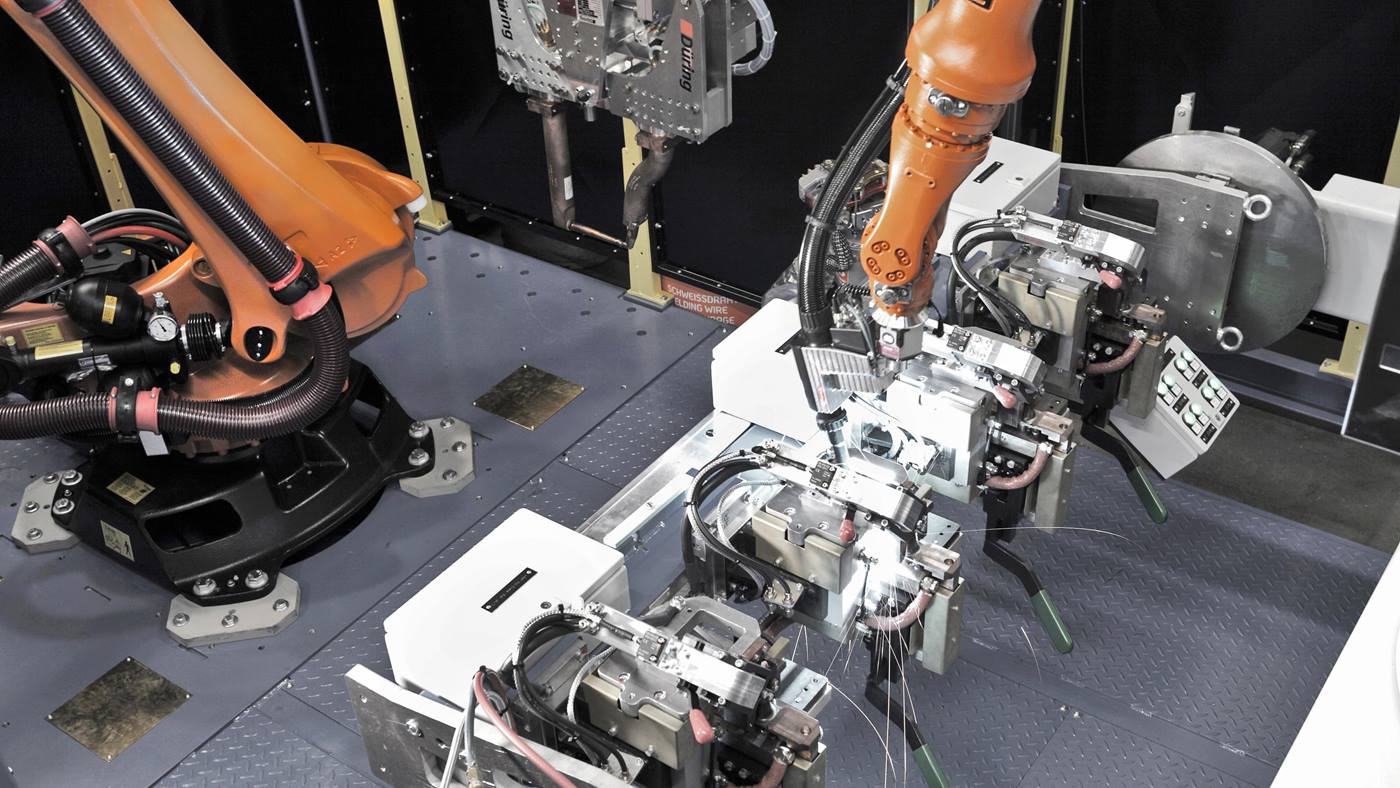

Innovative spot welding technology: from individual robots to complete systems

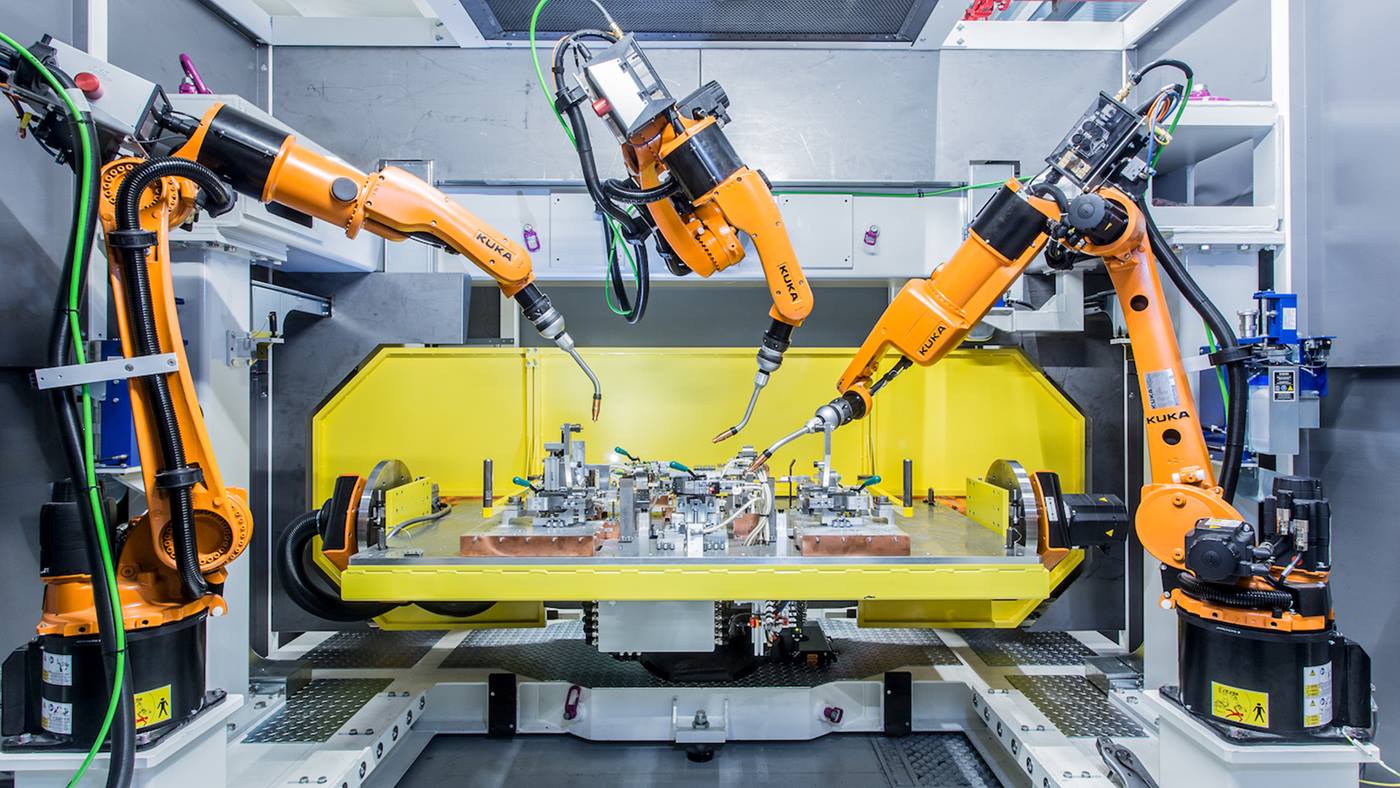

In spot or resistance welding, high mechanical pressure is applied to a relatively small area and a large amount of energy is applied in the form of an electric current. During the weld process, two electrodes press sheets of metal together and convert the welding current into heat at the metals contact surface, as a result of which a permanent fixed joint, or spot weld, is created between the two metal sheets.

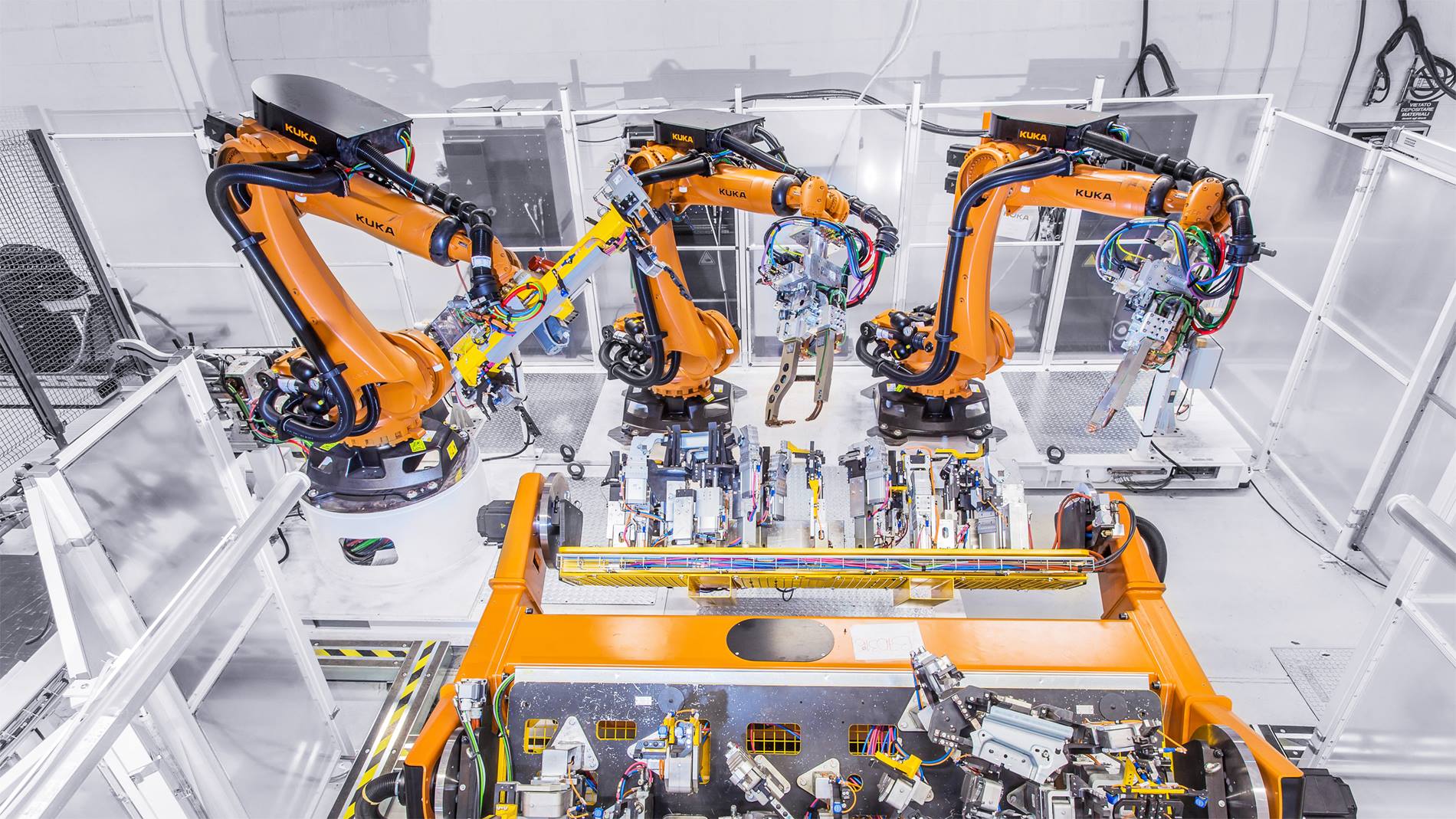

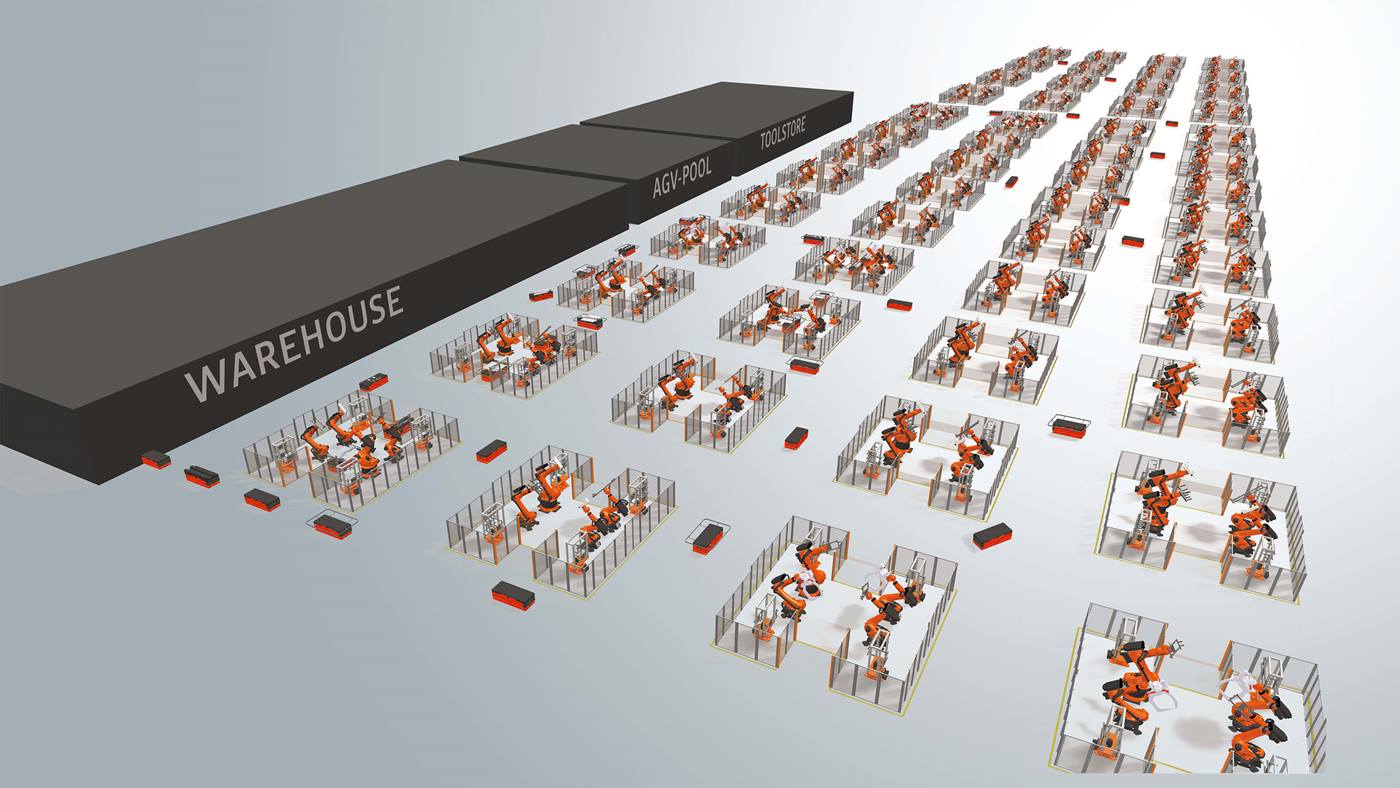

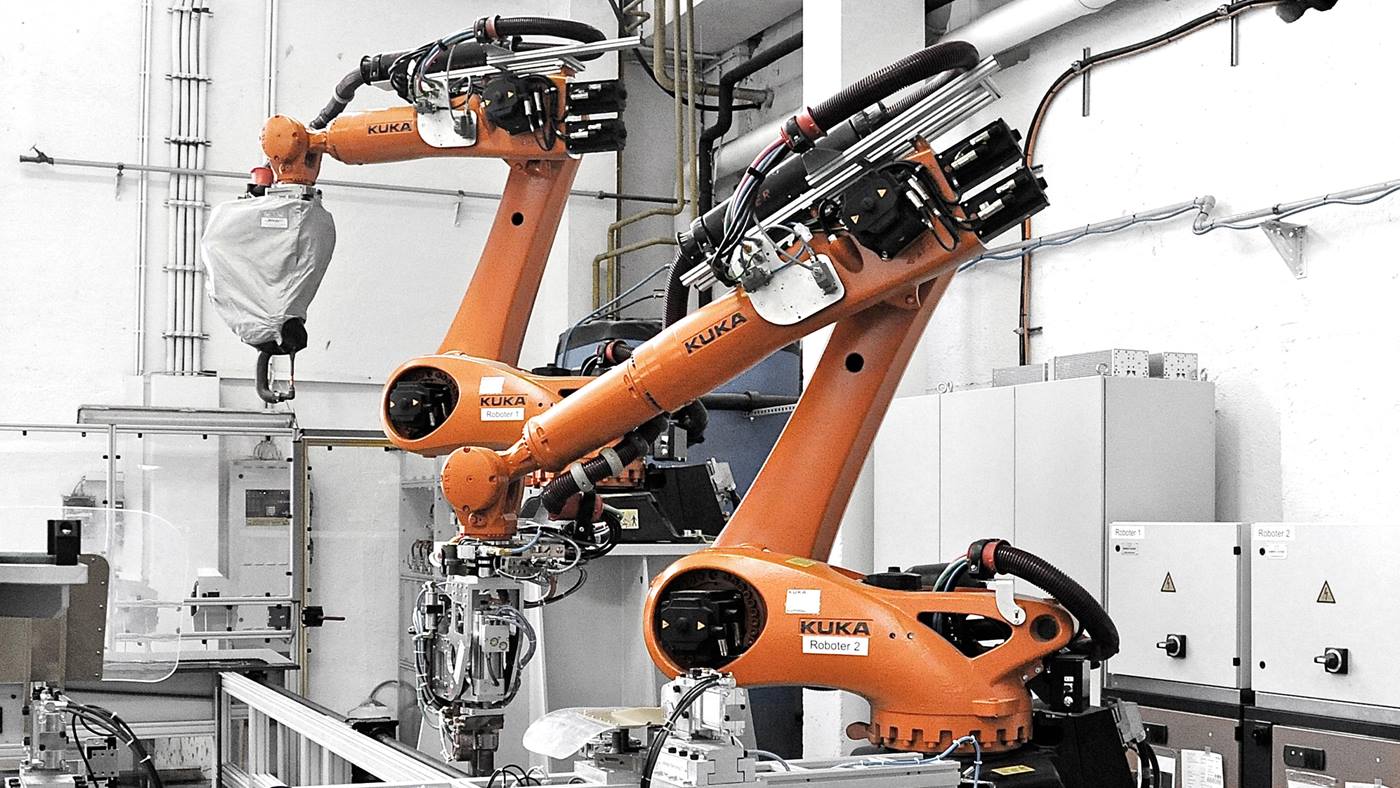

KUKA offers cost-effective and high-quality spot welding solutions for resistance spot welding, even for customer specific weld requirements. Our product's short delivery times enable individual solutions for the automation of spot welding - from welding robot arms with high payloads and optional additional axis to complete spot welding lines with perfectly matched components.