LVD lauchnes new robotic electric press brake cell

LVD Company nv introduces Dyna-Cell, a robotic bending cell featuring a high-speed electric press brake. The press brake and robot function as a compact, integrated unit to automate the bending of small- to medium-sized parts in varying batch sizes at bending speeds up to 25 mm per second. Dyna-Cell made its debut at EuroBLECH

Productive and Reliable: The KUKA CYBERTECH robot in Dyna-cell

Dyna-Cell incorporates a stacking area with space to load and unload several pallets. Finished parts are offloaded by the KUKA robot on to the appropriate pallet. When bending a large volume of small parts, no operator intervention is required for up to eight hours of automated production. Dyna-Cell’s design concept also allows for unmanned or manned operation offering a perfect bending solution for small / medium and large batch sizes.

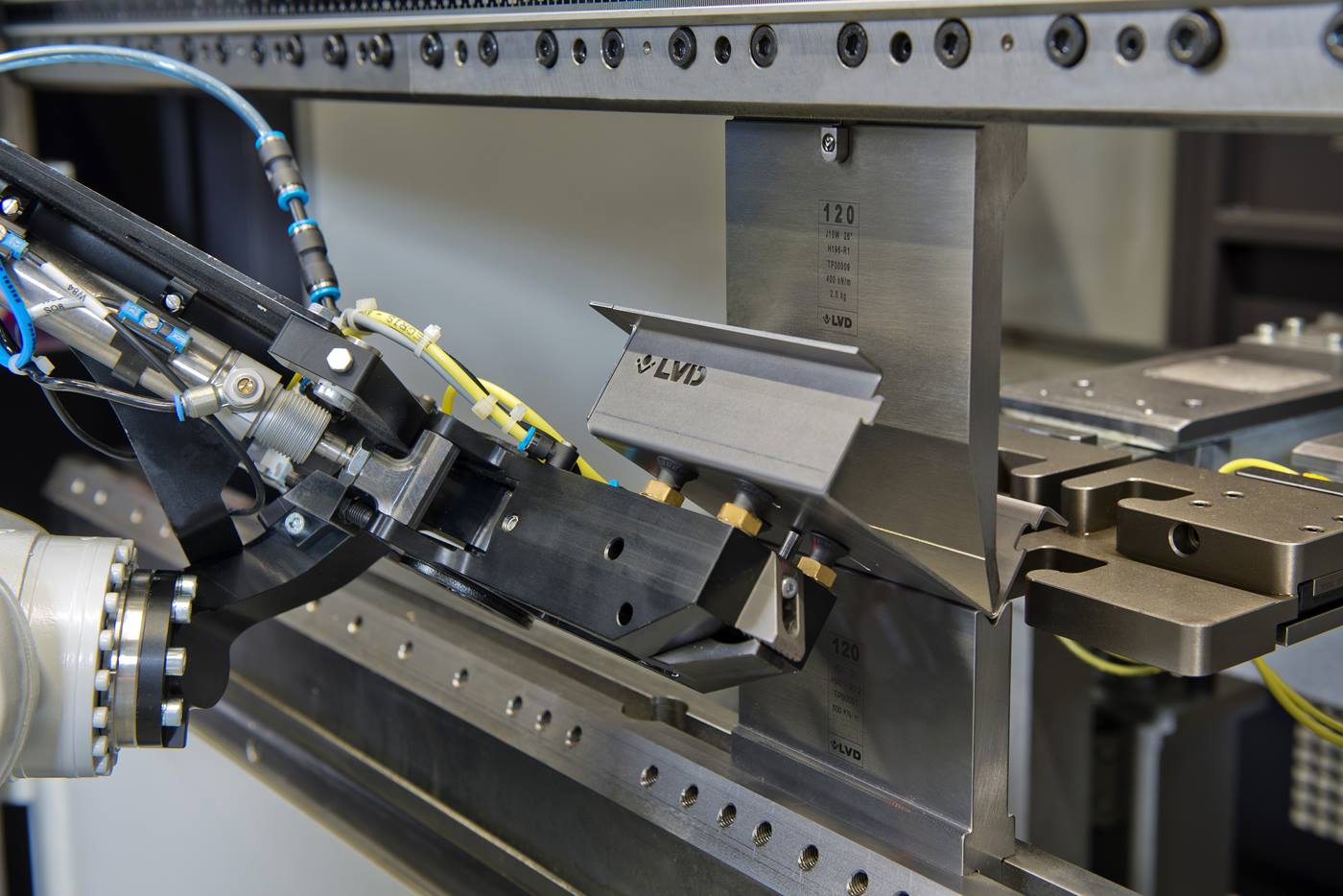

Universal Gripper: All sizes possible with only 1 gripper

Fast programming: 10 Minutes CAM - 10 Minutes set-up

Dyna-Cell is equipped with the latest generation LVD Touch-B 15” touch screen control, which is fully integrated with the LVD CADMAN® software suite