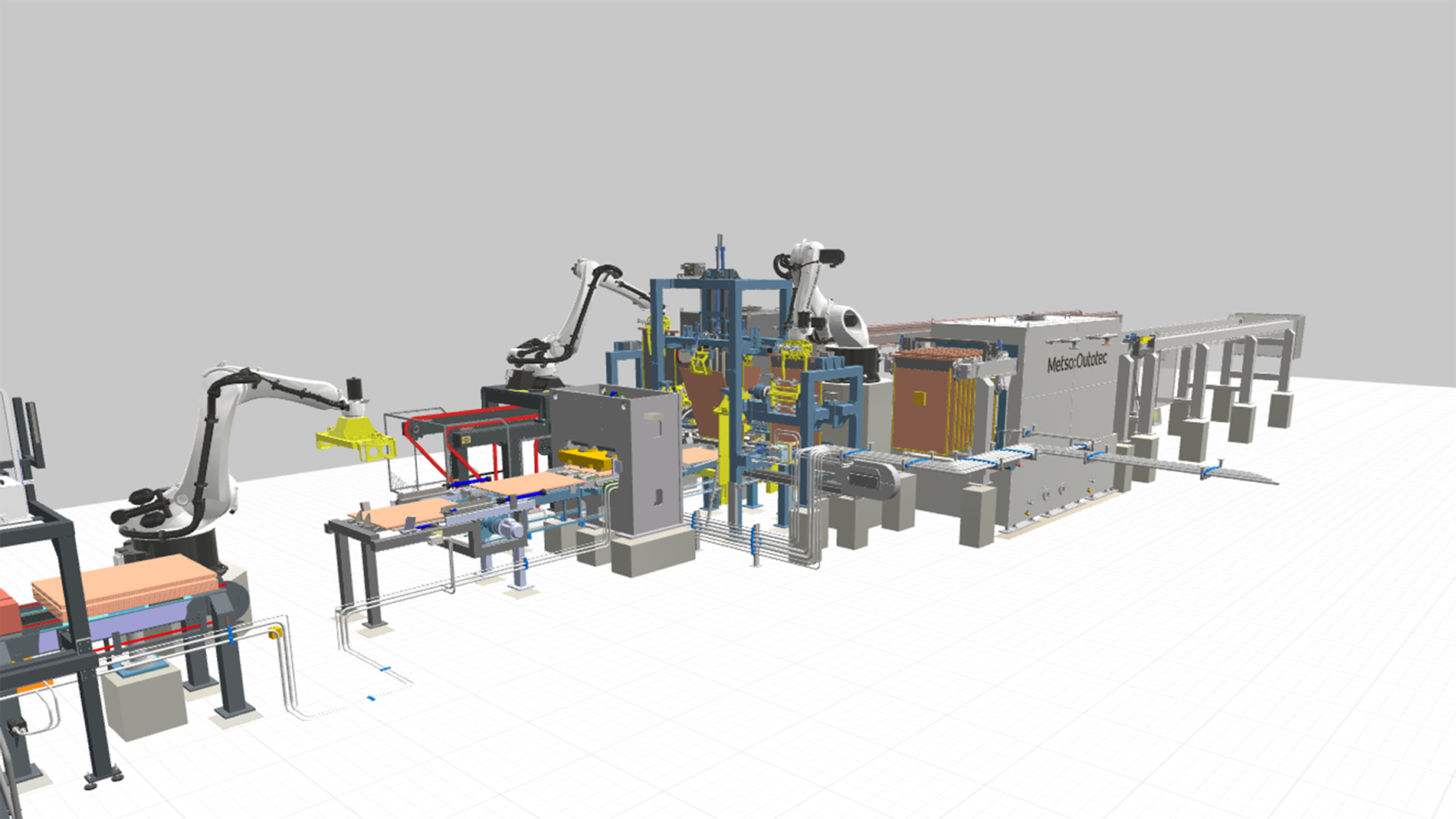

Create and test your industrial lines directly in the computer.

There has been a real shift in how to create and build production lines. What has traditionally been a hands-on job, where everything was planned in rough sketches designed in CAD systems, manufactured, assembled and finally tested on site, is starting to become more and more something that can be done in a regular laptop equipped with a simulation program. One who was early to invest in the technology is Henrik Jönsson, automation engineer at the system integrator Metso Outotec in Kil. For Henrik Jönsson, it is the simulation program KUKA.Sim that has opened up a completely new way of working. - At first we only used it to simulate robots, then I discovered that we had just scratched the surface, he says. In the program - developed by the robot manufacturer KUKA - it is possible to build and test industrial lines directly in the computer.