Hậu cần nội bộ được tối ưu hóa trong các công ty truyền thống của Bavaria

Truyền thống Bavaria ở tầm cao. Công ty TNHH Xưởng thịt E. Zimmermann đã có từ khoảng năm 1894. Kể từ khi thành lập, công ty chỉ hoàn toàn sản xuất thực phẩm chất lượng cao theo công thức gia truyền. Khi nói đến xúc xích trắng với nhiều dạng đóng gói khác nhau, thì xưởng thịt Zimmermann là một trong những nhà sản xuất hàng đầu tại Đức. Yêu cầu về chất lượng cũng áp dụng cho việc xếp hàng lên tấm nâng trong môi trường sản xuất.

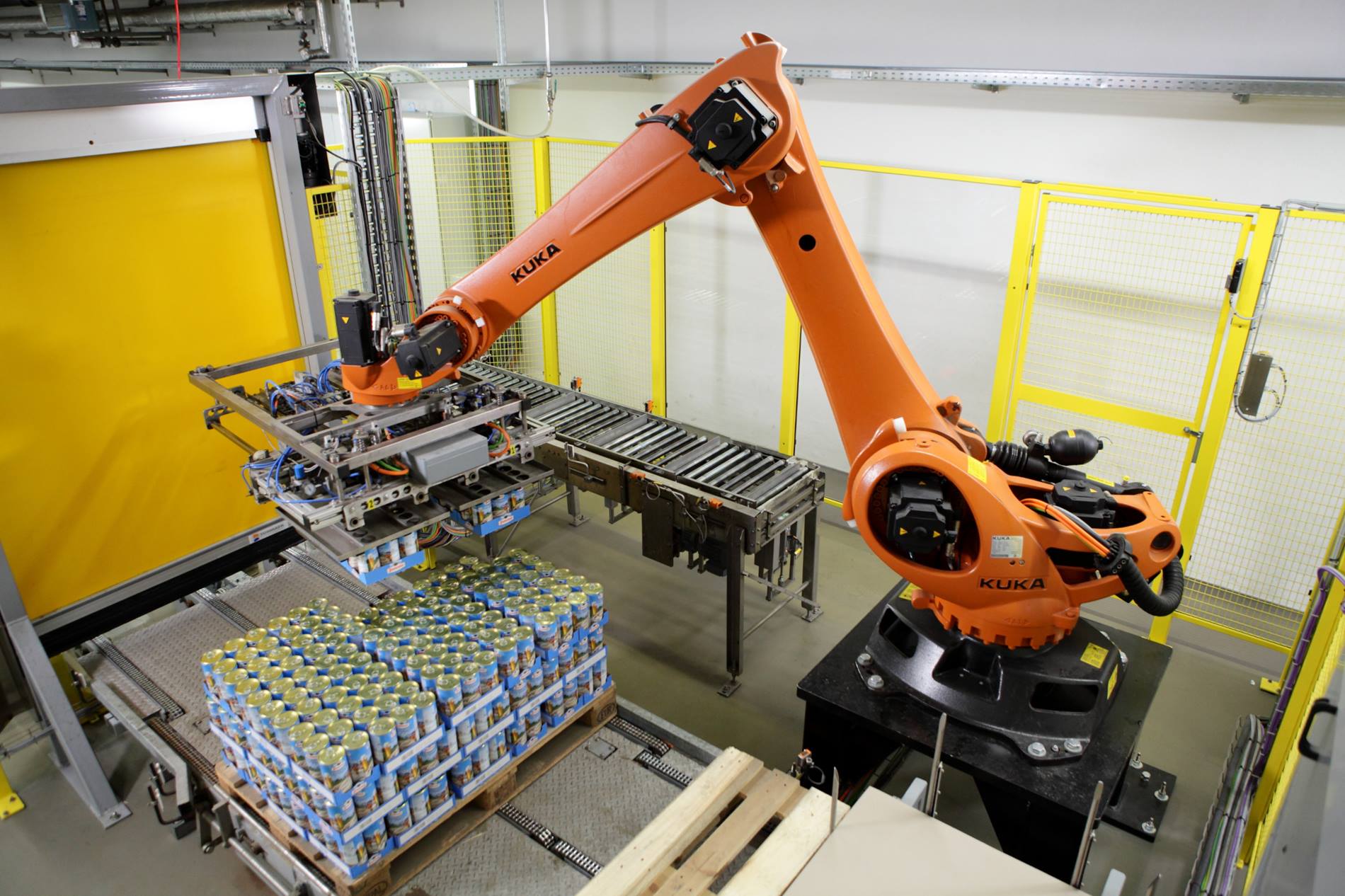

“Cho đến nay, việc xếp dỡ hàng hóa được thực hiện theo cách thủ công và không còn hợp lý về mặt công thái học đối với nhân viên. Đó là lý do tại sao chúng tôi quyết định tự động hóa quy trình”, Christian Lauer, Giám đốc Công nghệ tại xưởng thịt E. Zimmermann, giải thích. Để tối ưu hóa hậu cần nội bộ, một rô-bốt xếp hàng lên tấm nâng KUKA thuộc loại KR 12 R3200 PA được tích hợp vào quy trình.