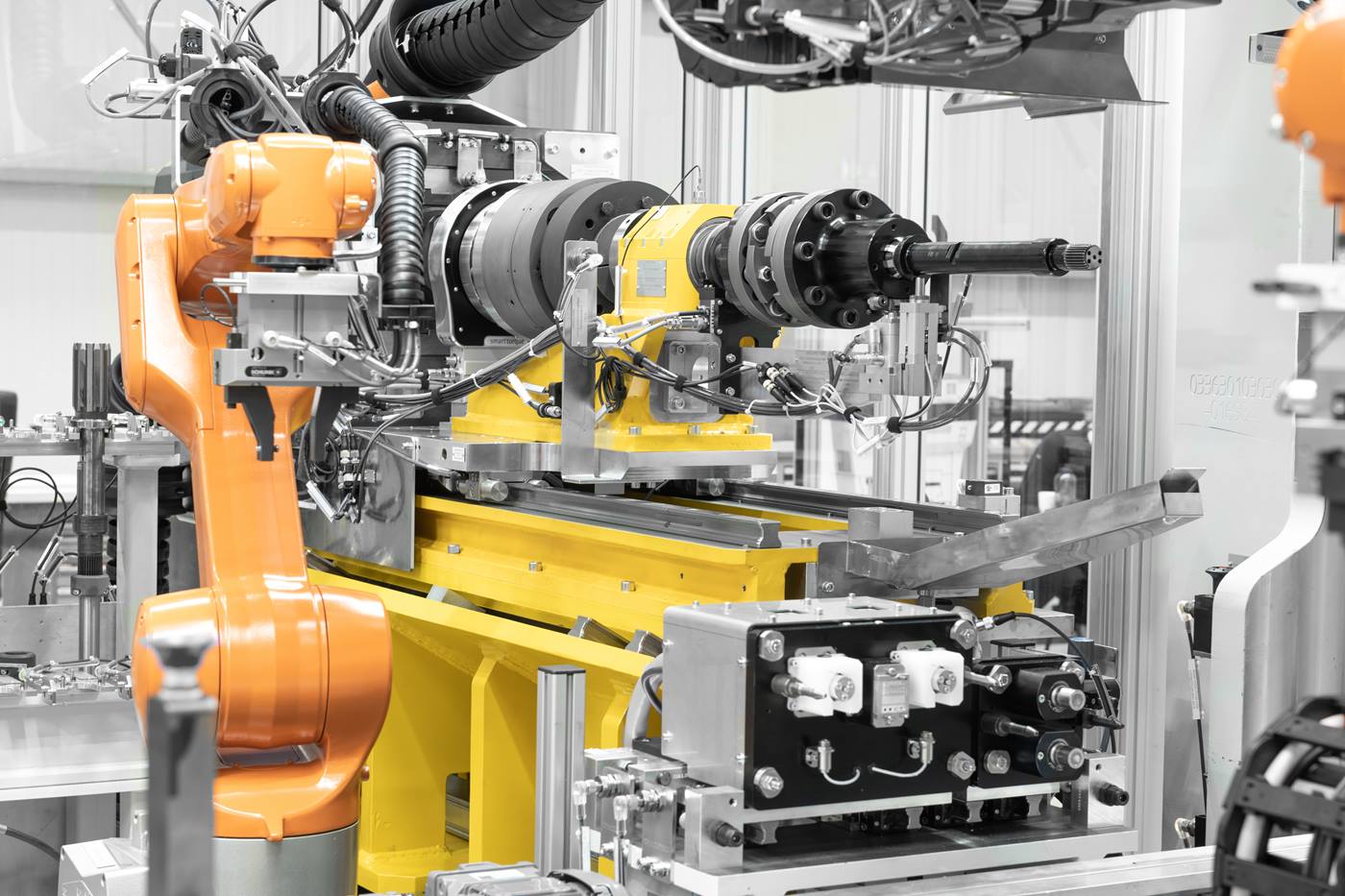

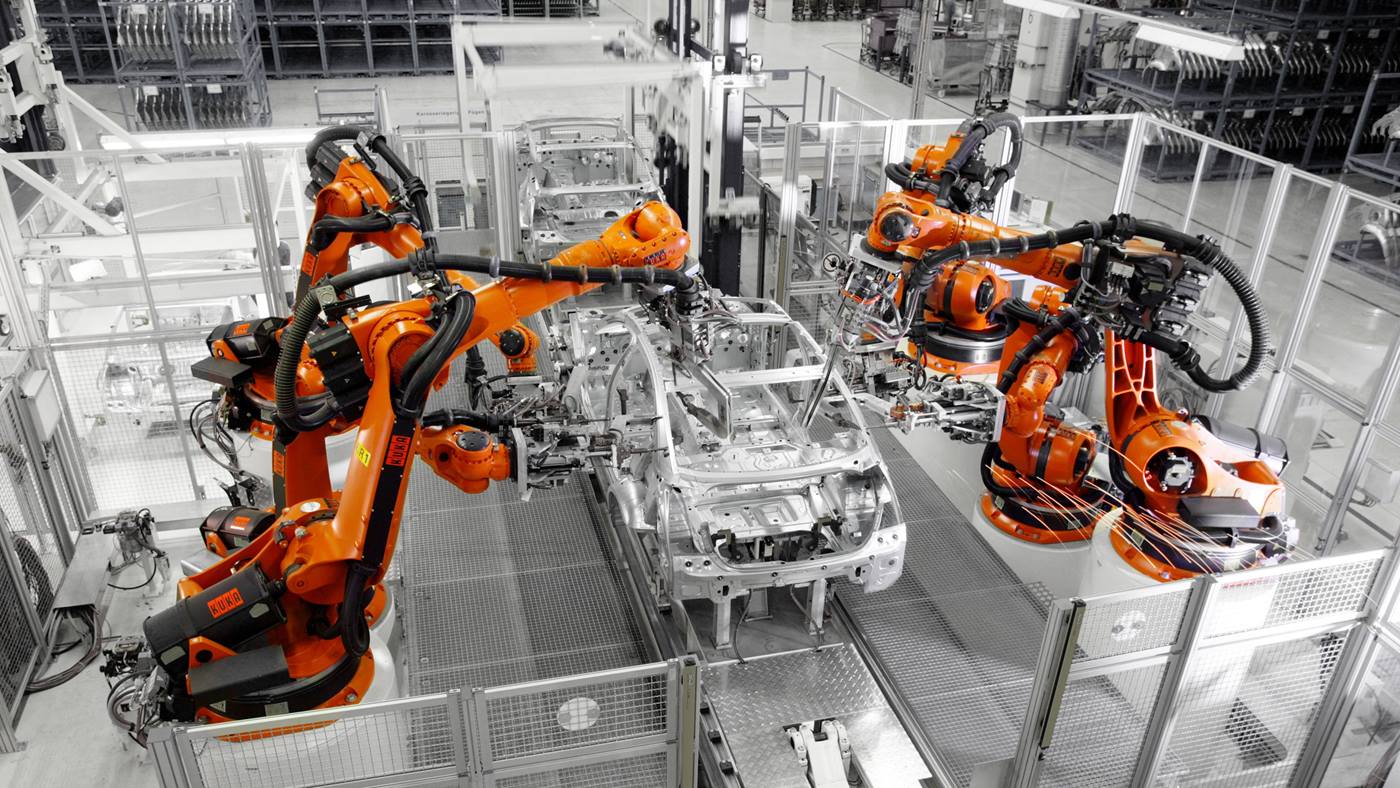

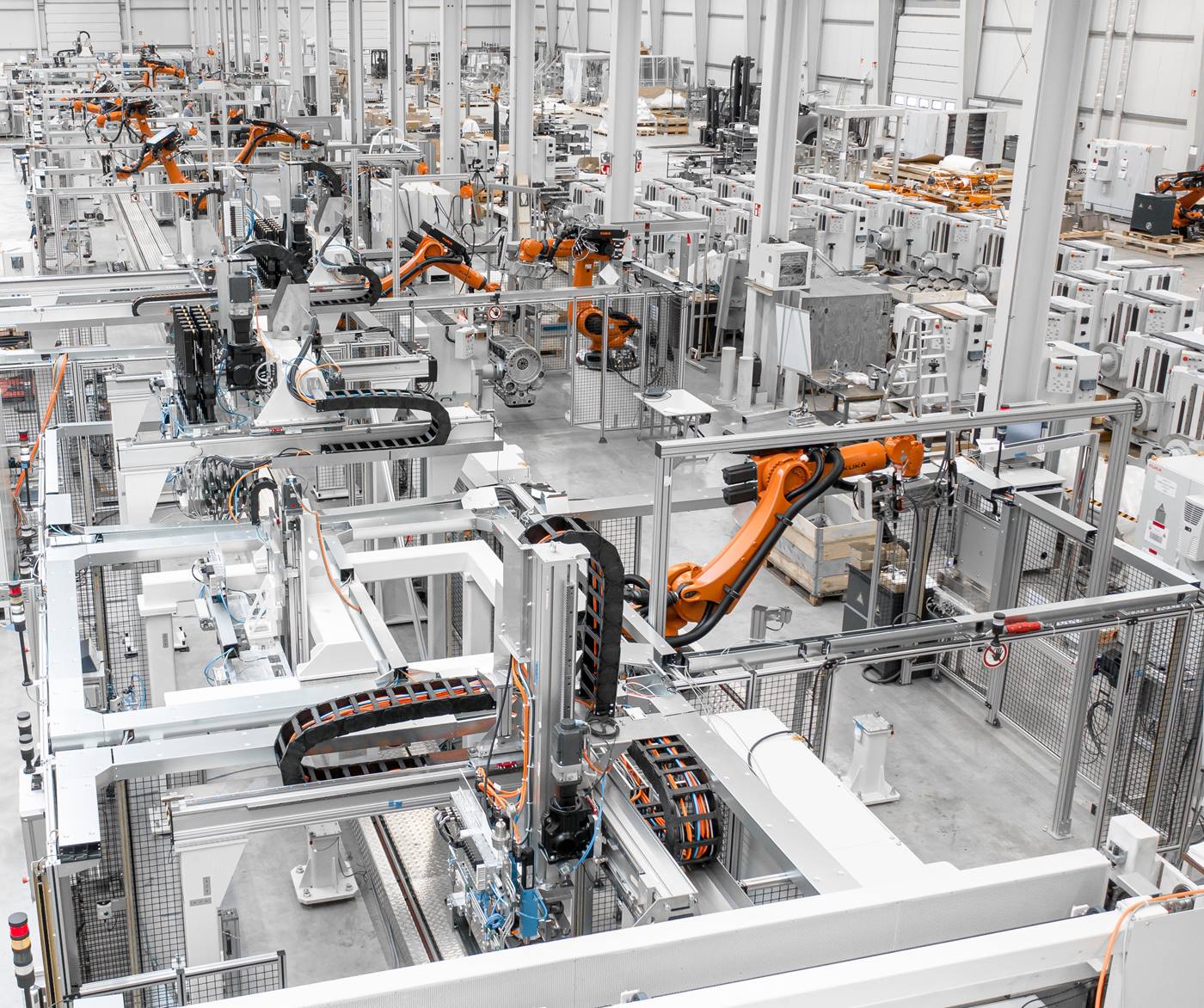

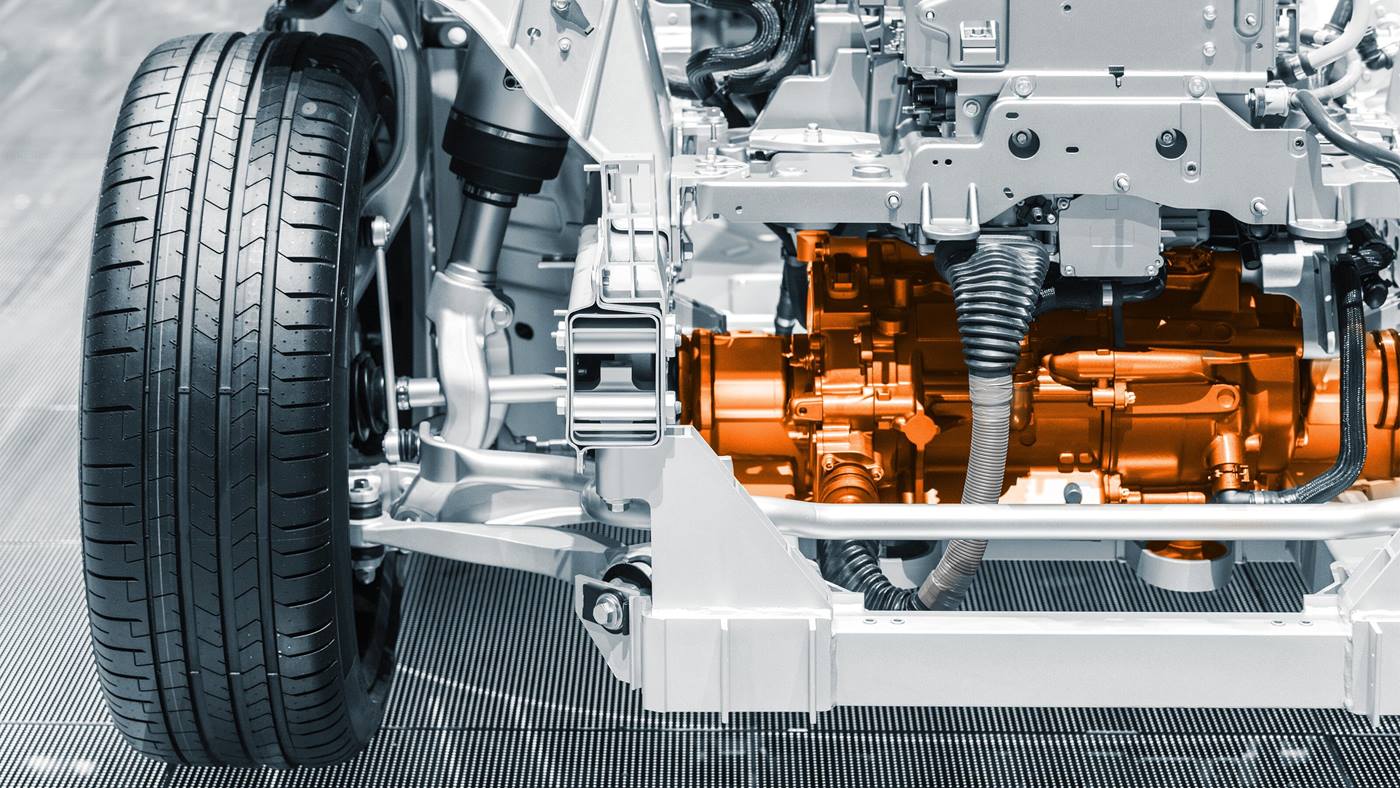

Electrified mobility: Automation solutions from KUKA

The transformation of the automotive industry is in full swing worldwide, and concepts for electrified and sustainable mobility are in demand. KUKA has also risen to the challenges in the production of electric vehicles and is perfectly positioned in the field of intelligent automation for electromobility.