KUKA rotary friction welding machines

KUKA friction welding machines are produced in Augsburg. Our broad product portfolio offers machines with forge forces between 1 and 10,000 kN. In addition to our standard machines for universal use, we also offer special machines customized to your product and process.

Customized special machines

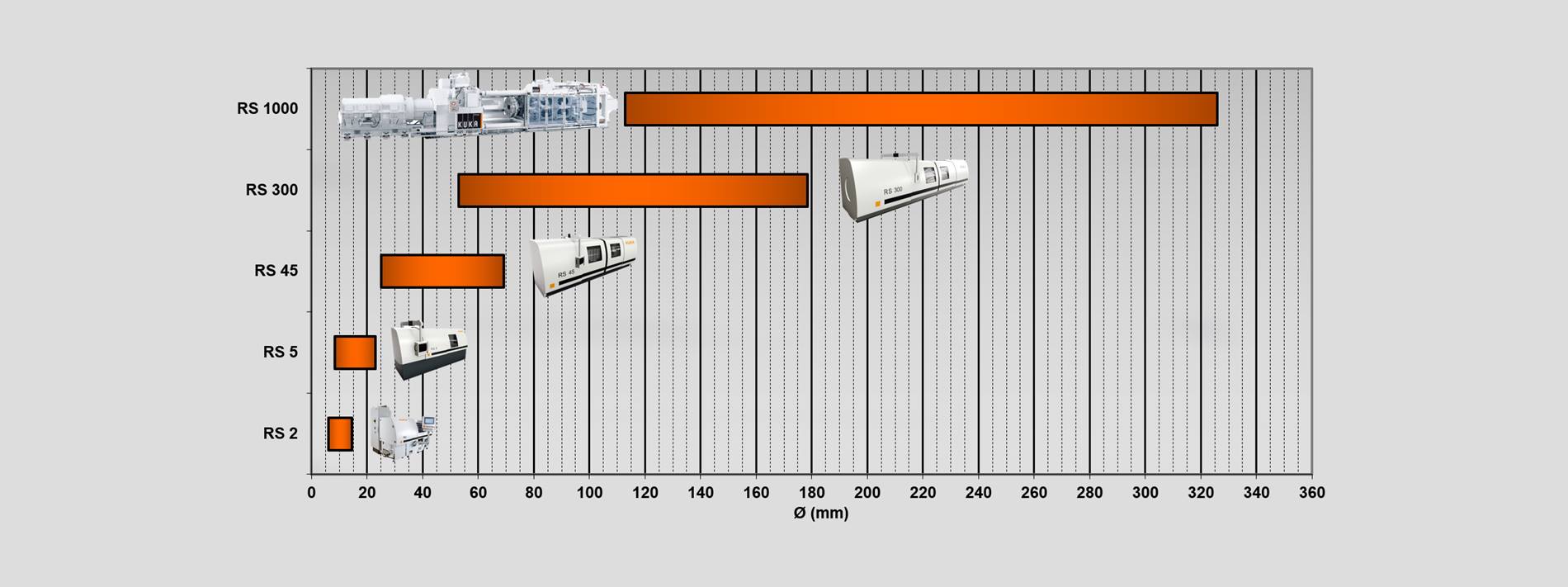

Do you have special components that can't be welded by our standard machines or would you like a special configuration? Then we at KUKA offer the right solution with our special machines from the RS-family. A selection is shown in the following graphic. Other configurations are possible on request.