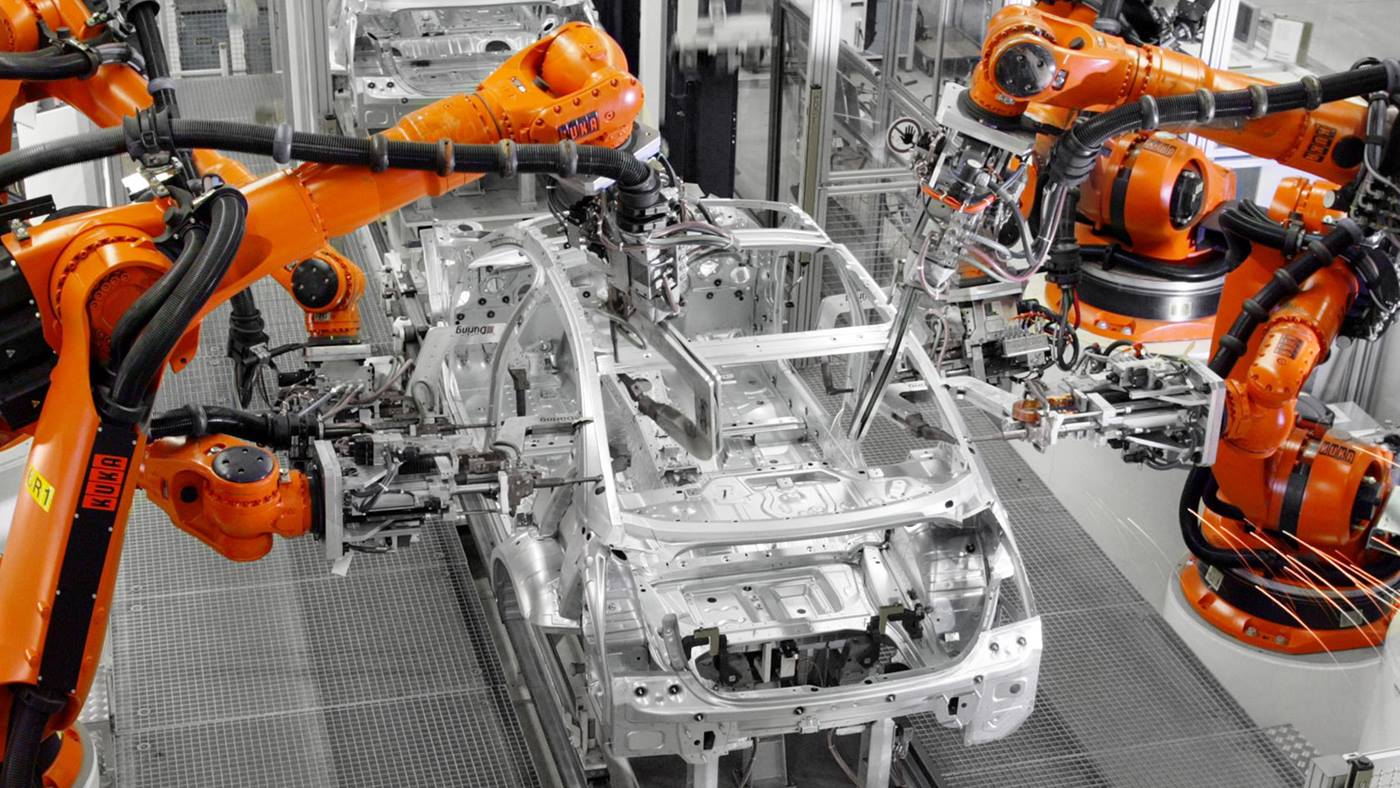

Engineering: experts for your automated production

As experts for production automation KUKA high-efficiency solutions based on our many years of experience in systems integration and comprehensive engineering services. KUKA stands for engineering on time, on budget and with short development periods.

Walk through your production shop of tomorrow, today. We create virtual three-dimensional models of your products and systems and develop the complete process chain. Virtual commissioning transfers part of the real commissioning procedure into the digital model world. KUKA thus lays the foundation for seamless integration of all system components.

Simple control of complex systems

Intelligent controllers allow KUKA to implement complex systems and achieve precise control over critical process parameters, thus delivering highly efficient solutions for production automation. Perfectly matched software of the system components – from the individual robot to the overall system – is a key element of KUKA’s engineering solutions. Our engineering makes it possible to manage and exchange data efficiently and facilitate the modular integration of data on a consistent, neutral platform. KUKA places great importance on simple programming and user-friendly operator control.

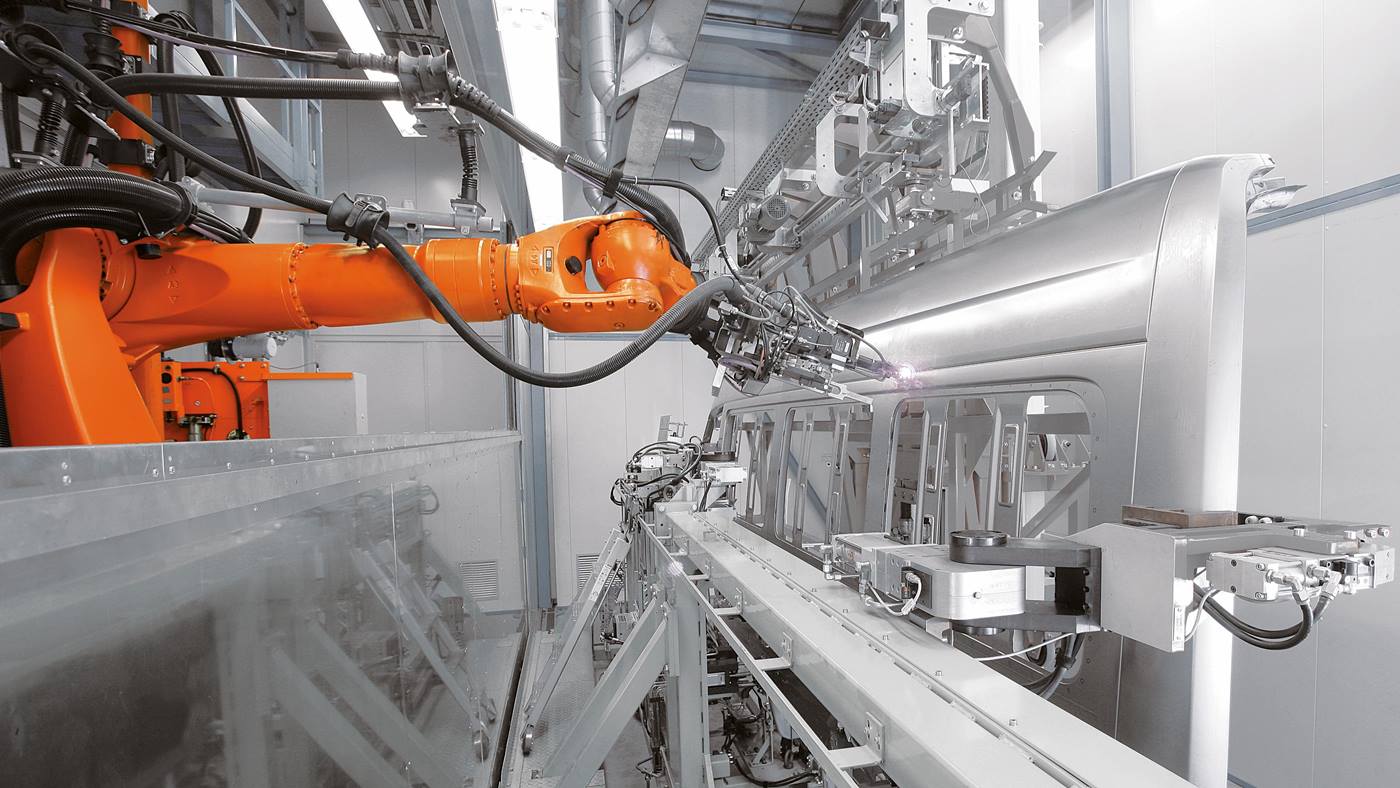

Fault-free production with intelligent sensor systems

Vision systems and sensor technologies monitor your manufacturing processes. This includes intelligent camera systems which check the positioning of your workpieces so that positional tolerances are resolved before further processing stages. As experts for your automated production we integrate the appropriate sensor solution and thus avoid production defects.

Efficient material flow through KUKA engineering

We focus on the material flow and the logistics, right from the initial conception of the individual system layout. We develop efficient logistics and personnel concepts based on your production shop layout. In addition we perform reachability and accessibility analyses, and integrate transport systems between the stations.

Impartial and process-neutral

KUKA process and technology consulting is impartial and neutral with regard to selection of the suitable process, because only one result matters to us: the right engineering solution for your production.

Safeguarding investments by virtual engineering

Virtual commissioning significantly reduces the time for your development processes and avoids downtime and production loss. First we create virtual three-dimensional models of your systems and products, taking account of your resources and production shop layout. Not only the production machinery but also cabling routes, electrical resources and potential obstructions are included in the model so as to ensure an optimum robot unloading and safety concept for your production.

Then we integrate them into an end-to-end process chain and simulate the flow of materials in real time. Virtual engineering allows us to control, test, verify and optimize the material flow in the virtual model.

Then we integrate them into an end-to-end process chain and simulate the flow of materials in real time. Virtual engineering allows us to control, test, verify and optimize the material flow in the virtual model.

The advantages of virtual commissioning

Virtual commissioning transfers a major part of the real commissioning procedure into the digital model world. The advantages of virtual commissioning become clear especially when new components are being integrated and must interact with existing systems: avoidance of prolonged downtime and production loss.

End-to-end process chain

A critical factor for seamless integration of system components from multiple different manufacturers is their optimum interaction. Through virtual commissioning and use of the KUKA TechCenter we set up near-reality trials and deliver risk-free and reliable data. Virtual commissioning lays the foundation for seamless integration and an end-to-end process chain.