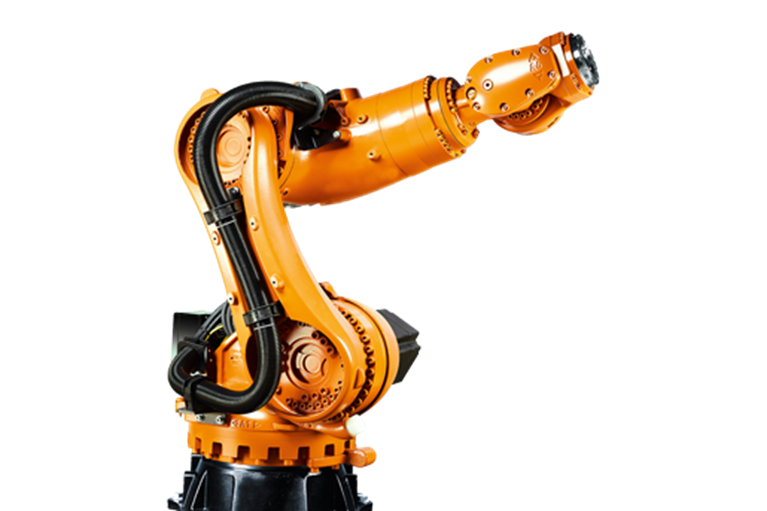

KR QUANTEC nano

The KR QUANTEC nano is the lightest and most compact robot in our KR QUANTEC series. It is particularly suitable for spot welding tasks and delivers outstanding process results at low investment costs.

The KR QUANTEC nano is the smallest and lightest robot in its class. Axis 3, which can swing over to the rear, makes for a large work envelope, with very good accessibility even in confined spaces. This is, for example, extremely helpful for tip dressing.

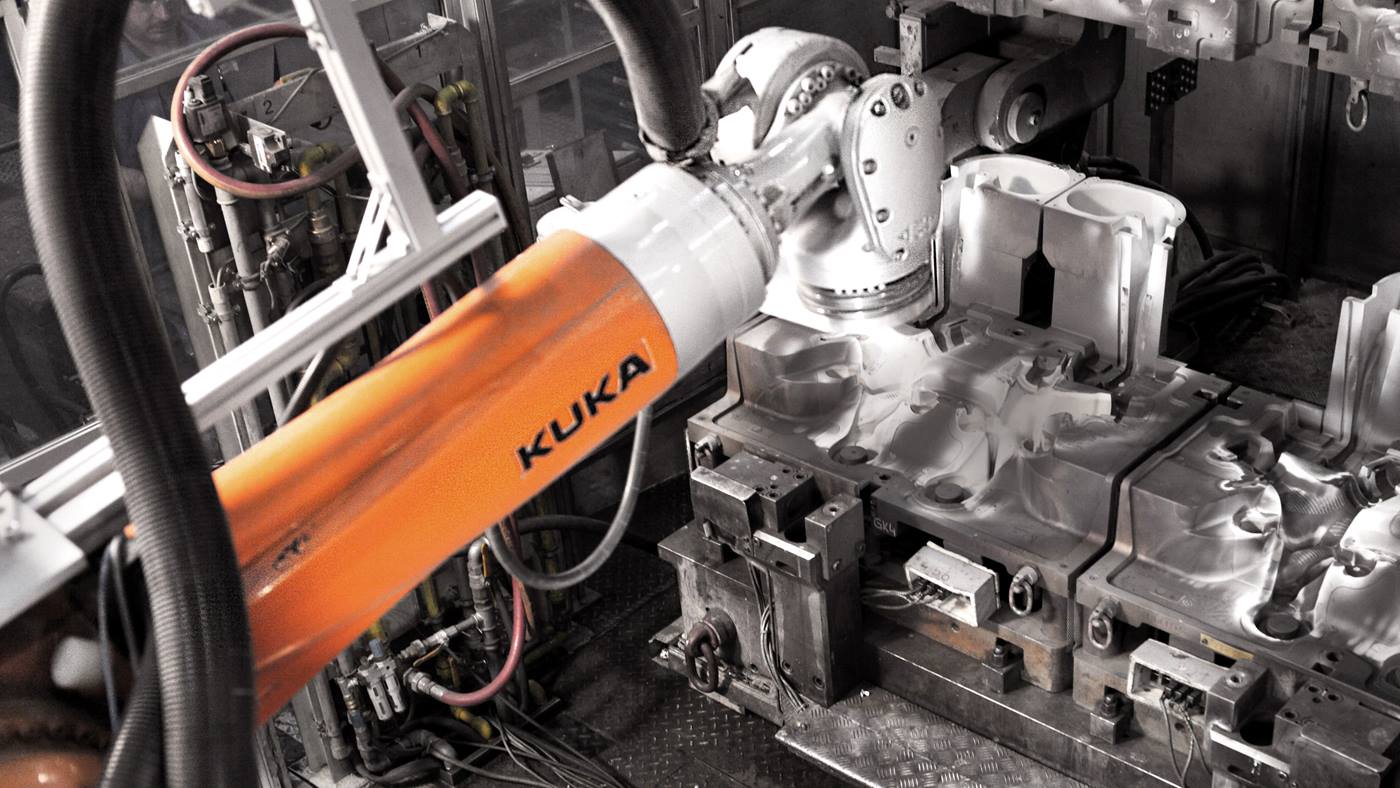

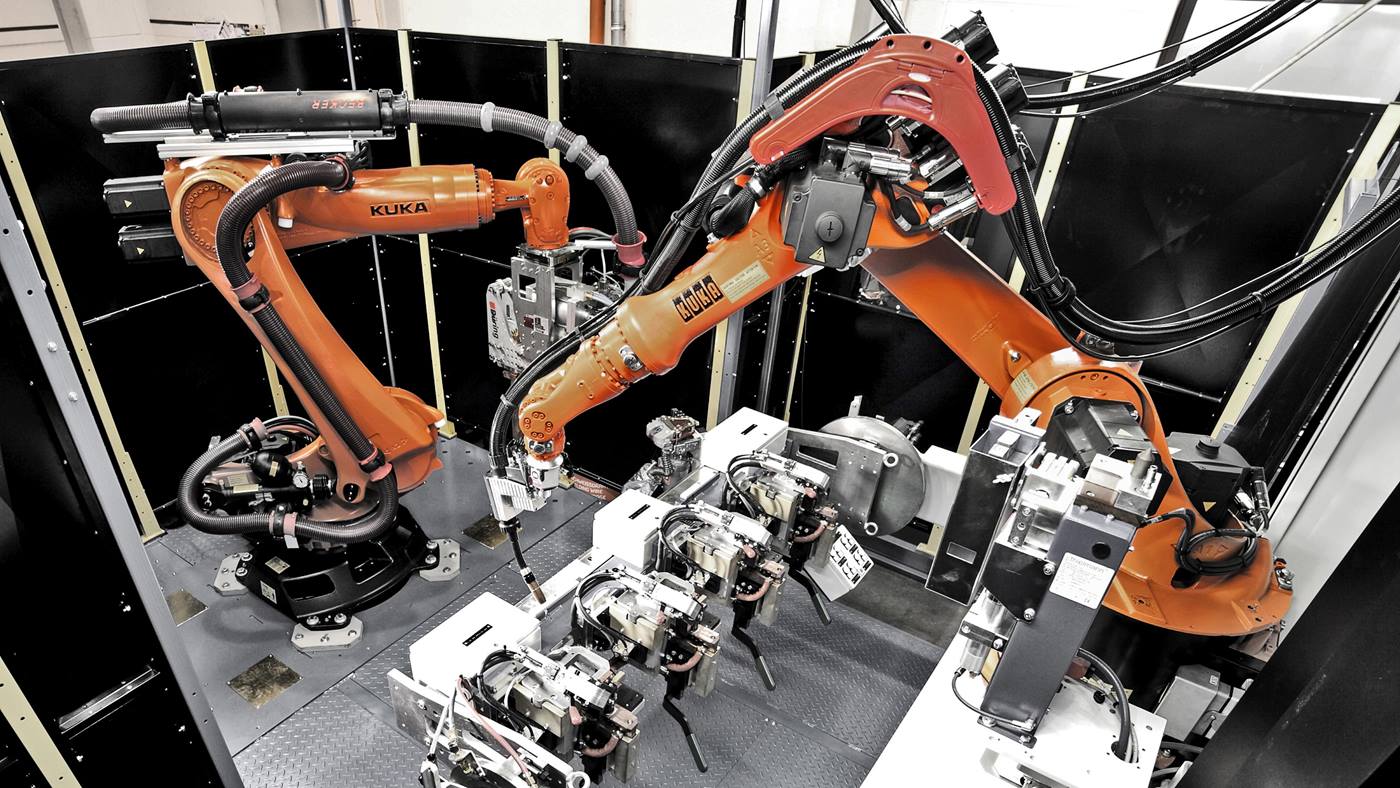

The KR QUANTEC nano F exclusive

The latest member of our KR QUANTEC nano series: the robust washing professional KR QUANTEC nano F exclusive. This compact foundry specialist has all of the characteristics of the KR QUANTEC Foundry series and is also specially optimized for the extreme conditions in cleaning systems and medium or large-sized washing cells. As such, we are able to make parts cleaning operations cost-effective, reproducible and environmentally friendly. The robot and its in-line wrist comply with protection ratings IP 65, IP 67 and IP 69.

With the KR QUANTEC nano F exclusive, KUKA has set new standards for comprehensive automation solutions in the foundry and engine production sectors.

With the KR QUANTEC nano F exclusive, KUKA has set new standards for comprehensive automation solutions in the foundry and engine production sectors.

KR QUANTEC nano (6 axes) - technical data

Robots

Total load

Maximum reach

Version environment

Downloads

KR 120 R1800 nano

Total load

120 kg

Maximum reach

1803 mm

Version environment

Standard

Downloads

- Total load 120 kg

- Maximum reach 1803 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Floor

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 120 R1800 nano C

Total load

120 kg

Maximum reach

1803 mm

Version environment

Standard

Downloads

- Total load 120 kg

- Maximum reach 1803 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Ceiling

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 120 R2100 nano F exclusive

Total load

120 kg

Maximum reach

2100 mm

Version environment

Foundry exclusive

Downloads

- Total load 120 kg

- Maximum reach 2100 mm

- Construction type Standard

- Version environment Foundry exclusive

- Mounting positions Floor

- Protection class IP 65, IP 67, IP 69

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 160 R1570 nano

Total load

160 kg

Maximum reach

1573 mm

Version environment

Standard

Downloads

- Total load 160 kg

- Maximum reach 1573 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Floor

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 160 R1570 nano C

Total load

160 kg

Maximum reach

1573 mm

Version environment

Standard

Downloads

- Total load 160 kg

- Maximum reach 1573 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Ceiling

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 180 R2100 nano F exclusive

Total load

180 kg

Maximum reach

2100 mm

Version environment

Foundry exclusive

Downloads

- Total load 180 kg

- Maximum reach 2100 mm

- Construction type Standard

- Version environment Foundry exclusive

- Mounting positions Floor

- Protection class IP 65, IP 67, IP 69

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

%x of %y robots visible