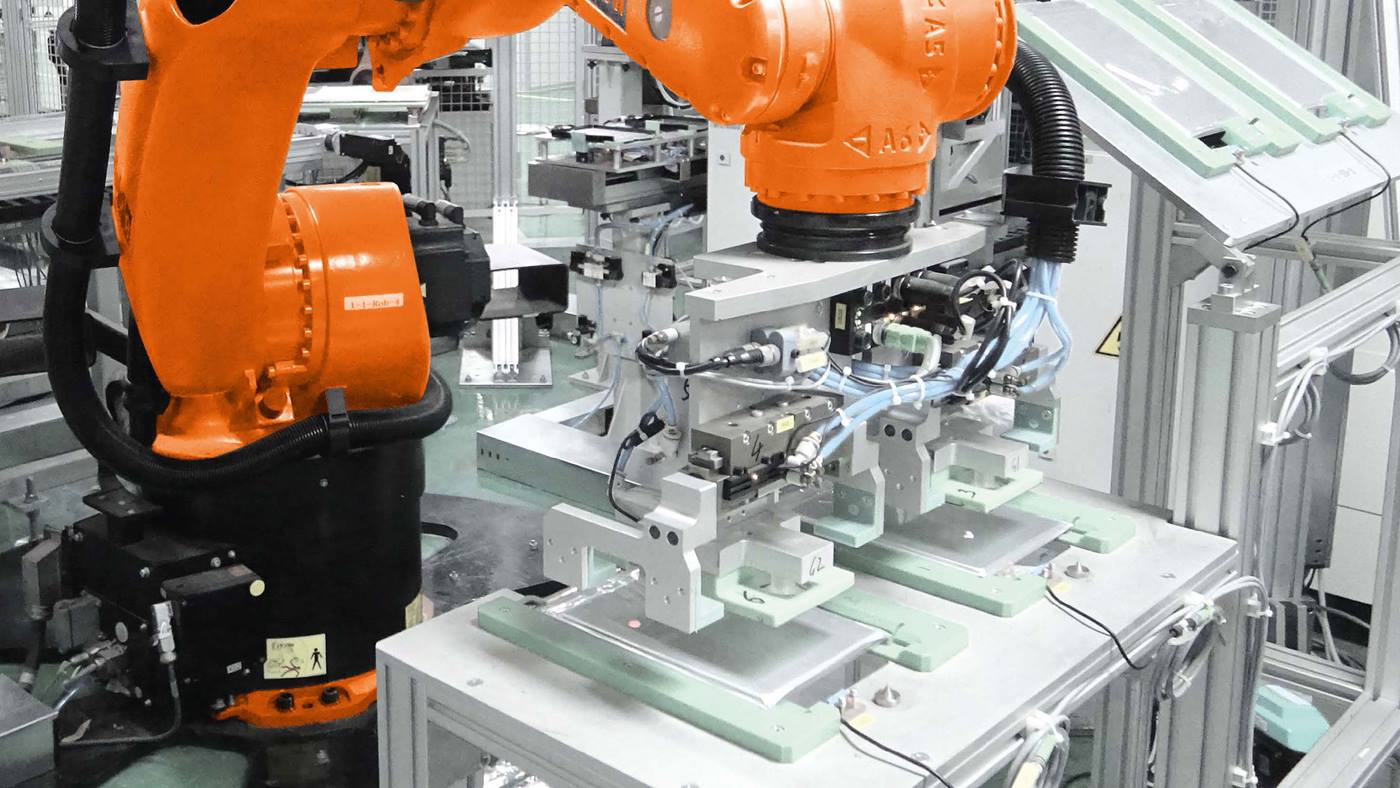

Laser welding: what does it actually involve?

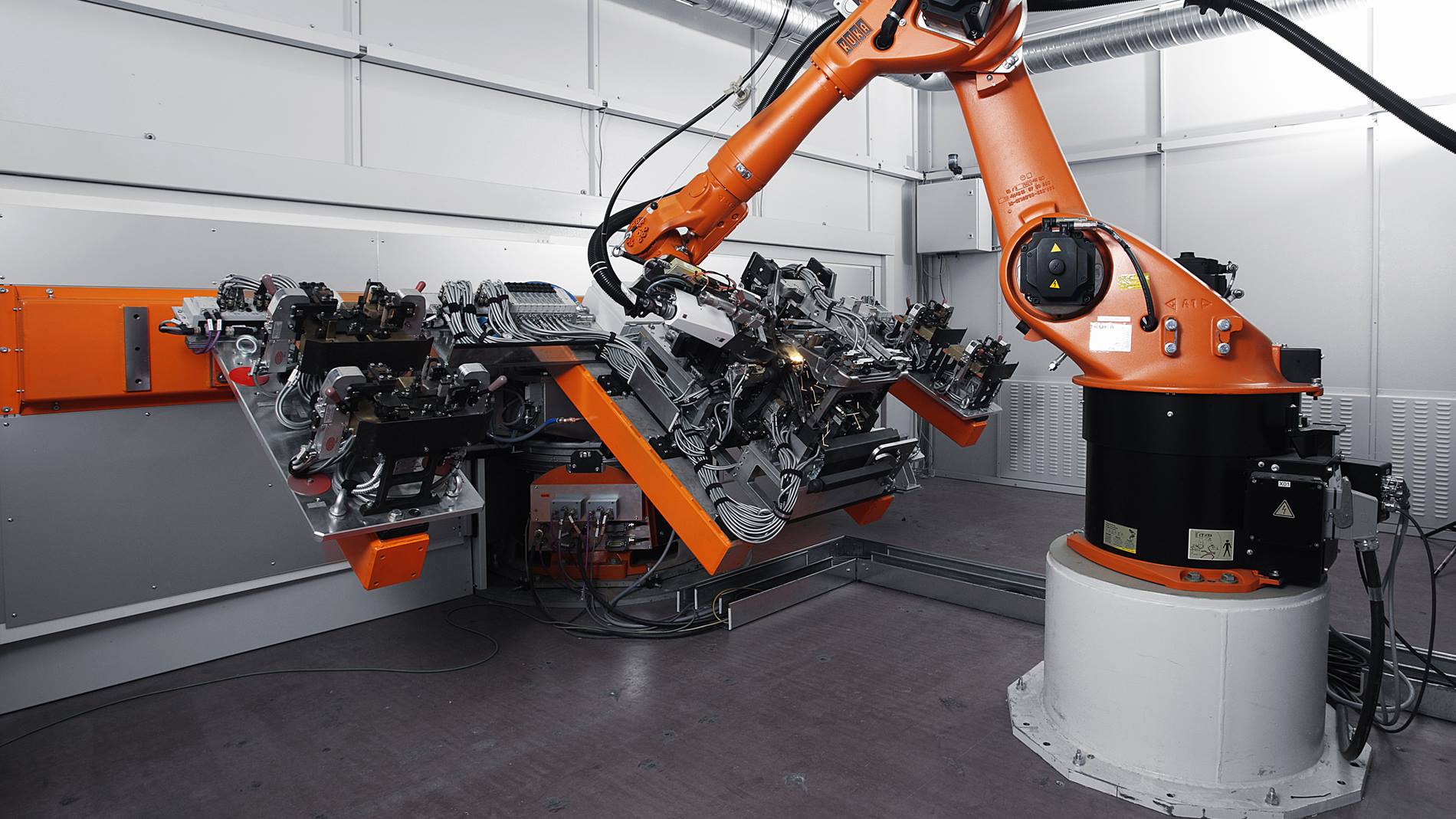

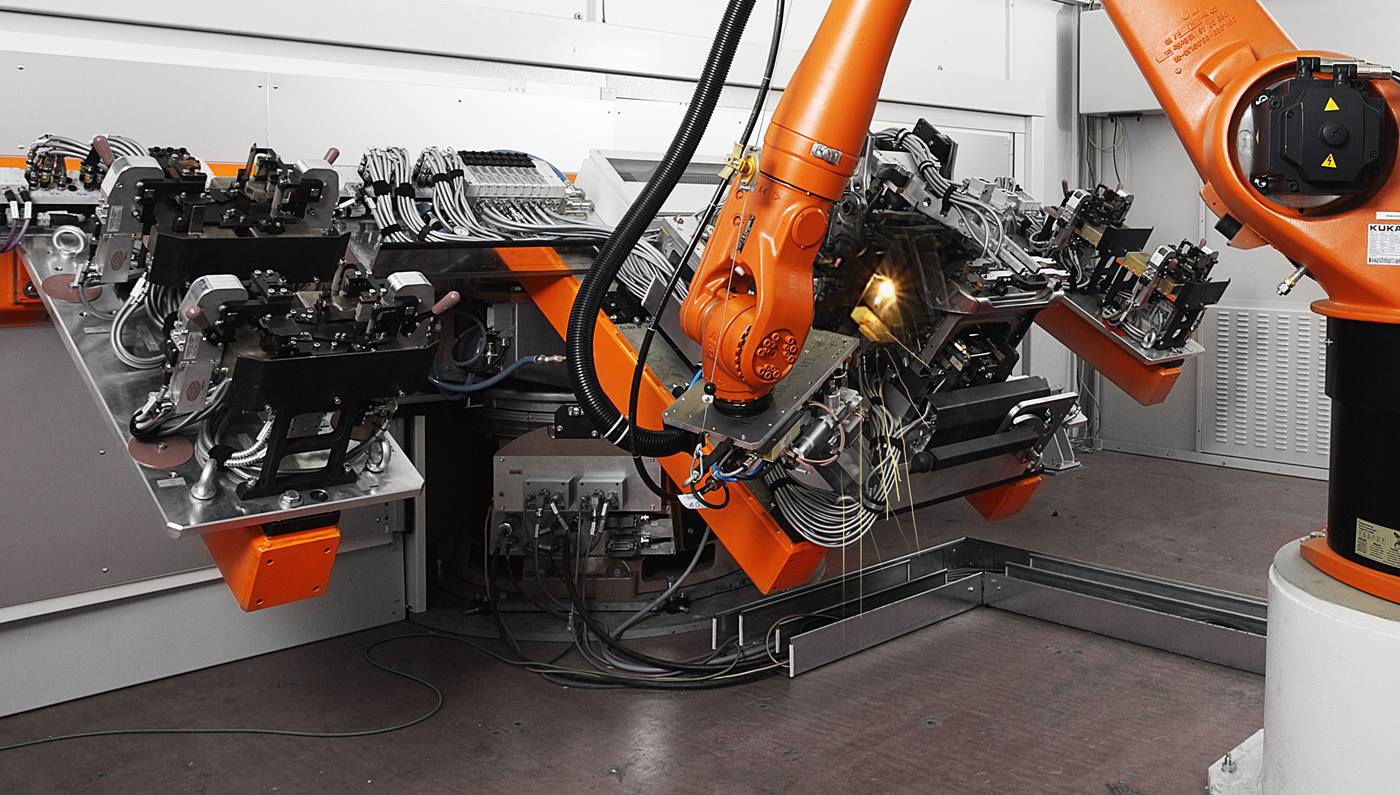

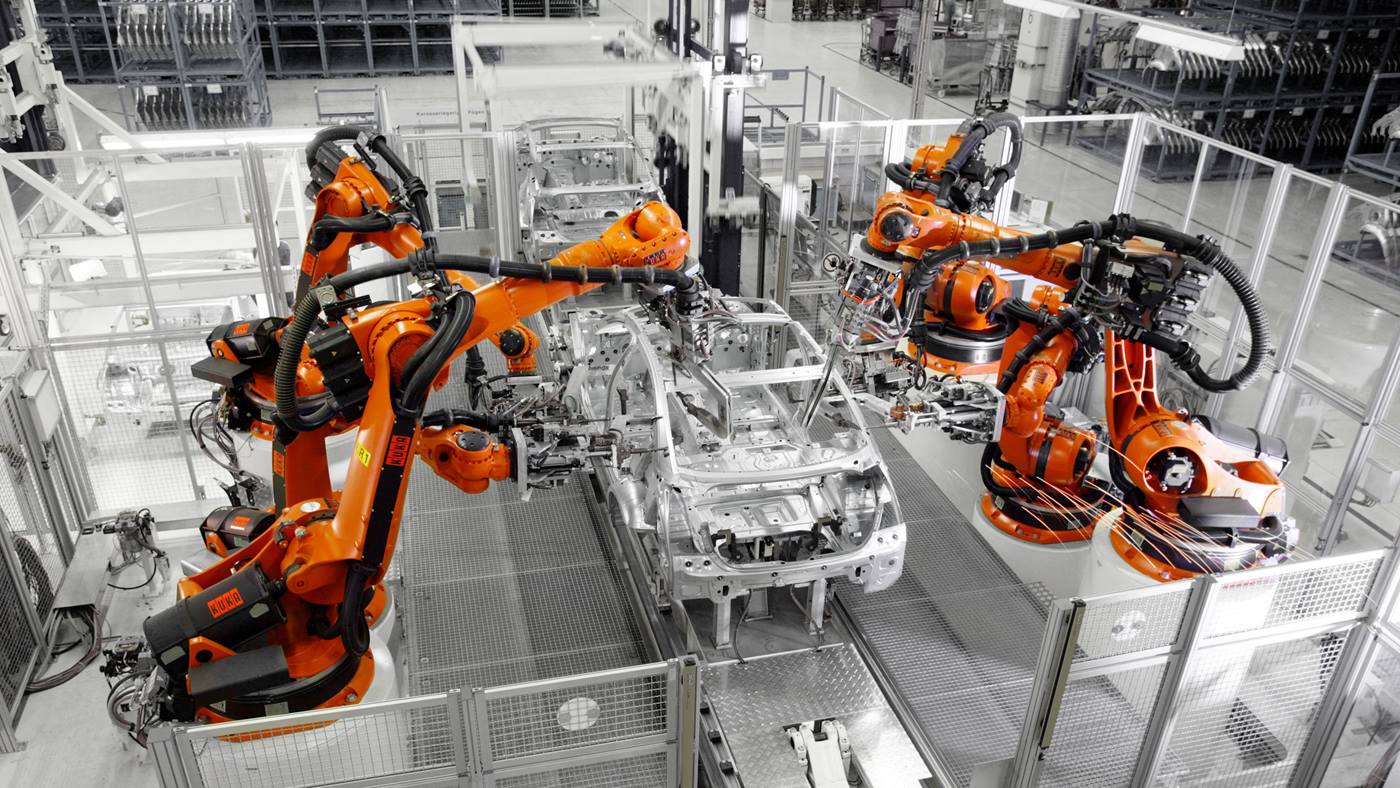

Laser welding is a joining process with a focused laser beam which is used in many industries due to its high precision. The energy for welding is generated by a high-performance laser. In robotic applications, the high-energy laser beam is usually guided by means of flexible optical fibers to the processing location. Here, the laser power is focused on a small focal spot with the aid of optics. The resulting high energy density melts the workpiece and welds the components.

The process is suitable for materials and components that are to be welded at high speed with a narrow weld seam and low thermal distortion. As a result, laser welding is used for high-precision applications in a wide range of industries, including the automotive, aerospace and medical sectors.