Robots in the cold storage: How KUKA automates frozen herb production at DARÉGAL

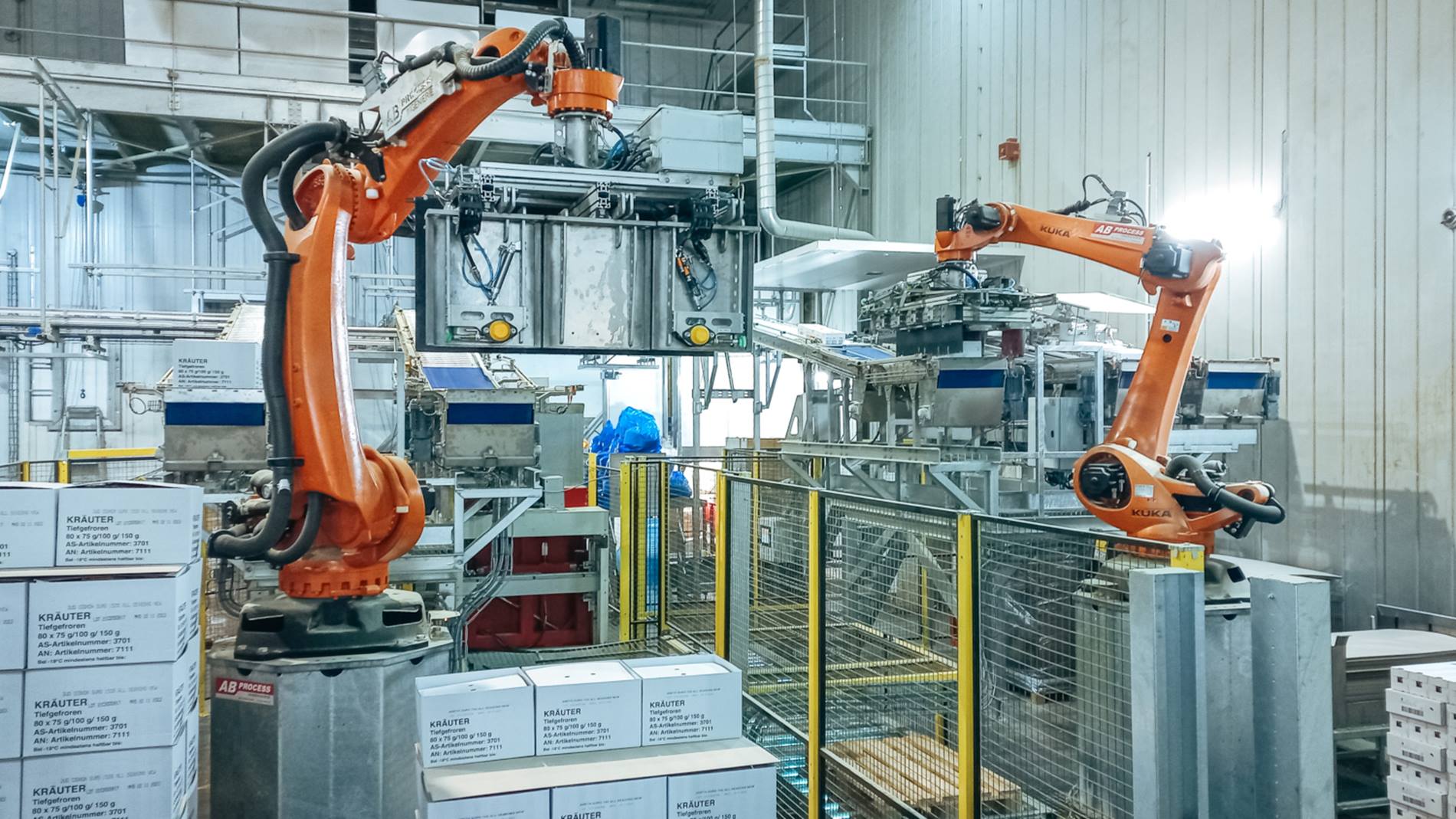

The KUKA robots work in the cold room at temperatures well below 0° C without protective suits, so their resistance to cold makes them ideal for food production. At DARÉGAL, they palletize small packages of frozen herbs at -25° C for delivery to restaurants and retailers. Before the robots came on board, employees had to perform this task manually on each of the packaging lines, which operate in three shifts, five days a week.