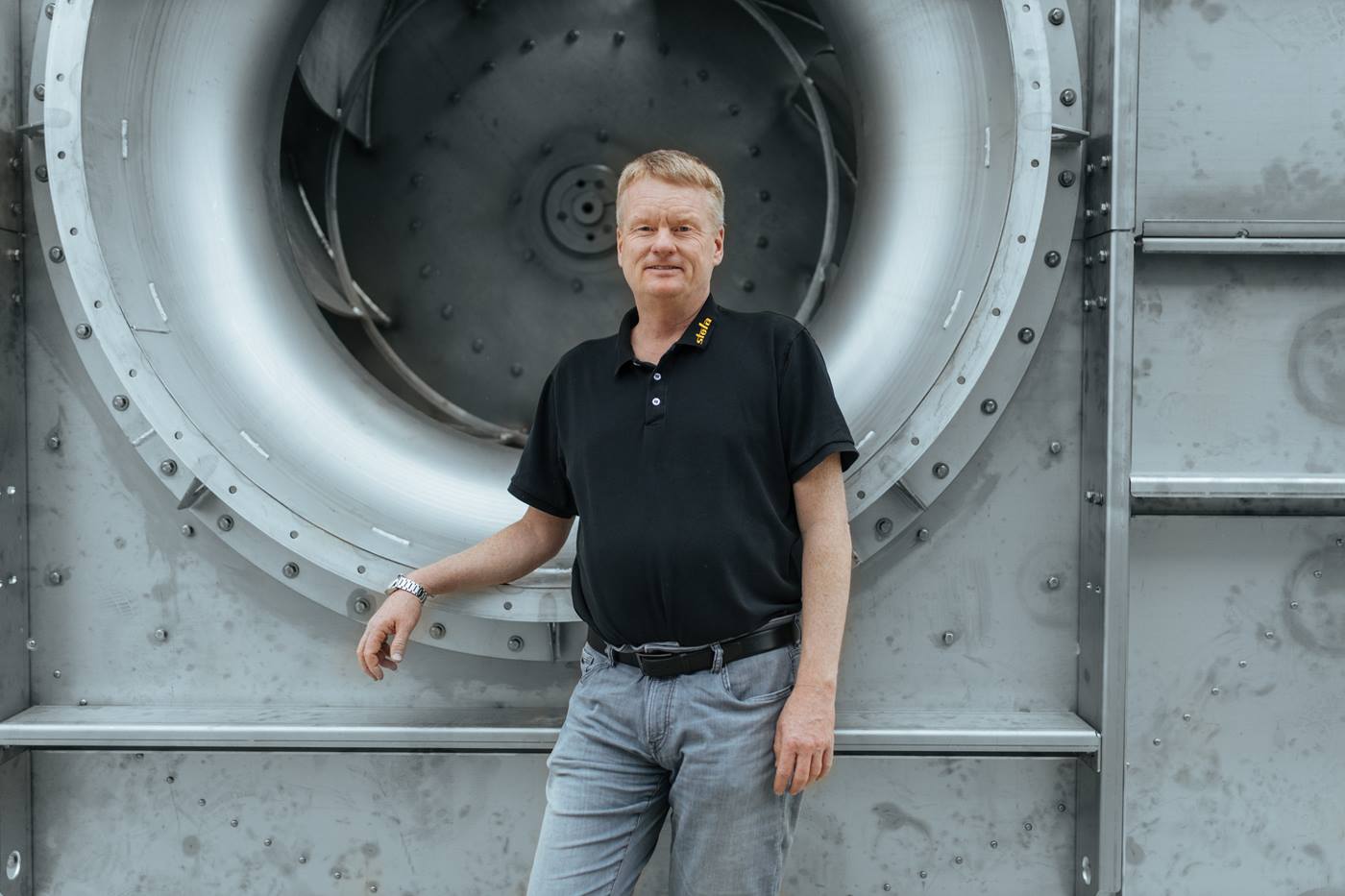

Keep the production in the own company

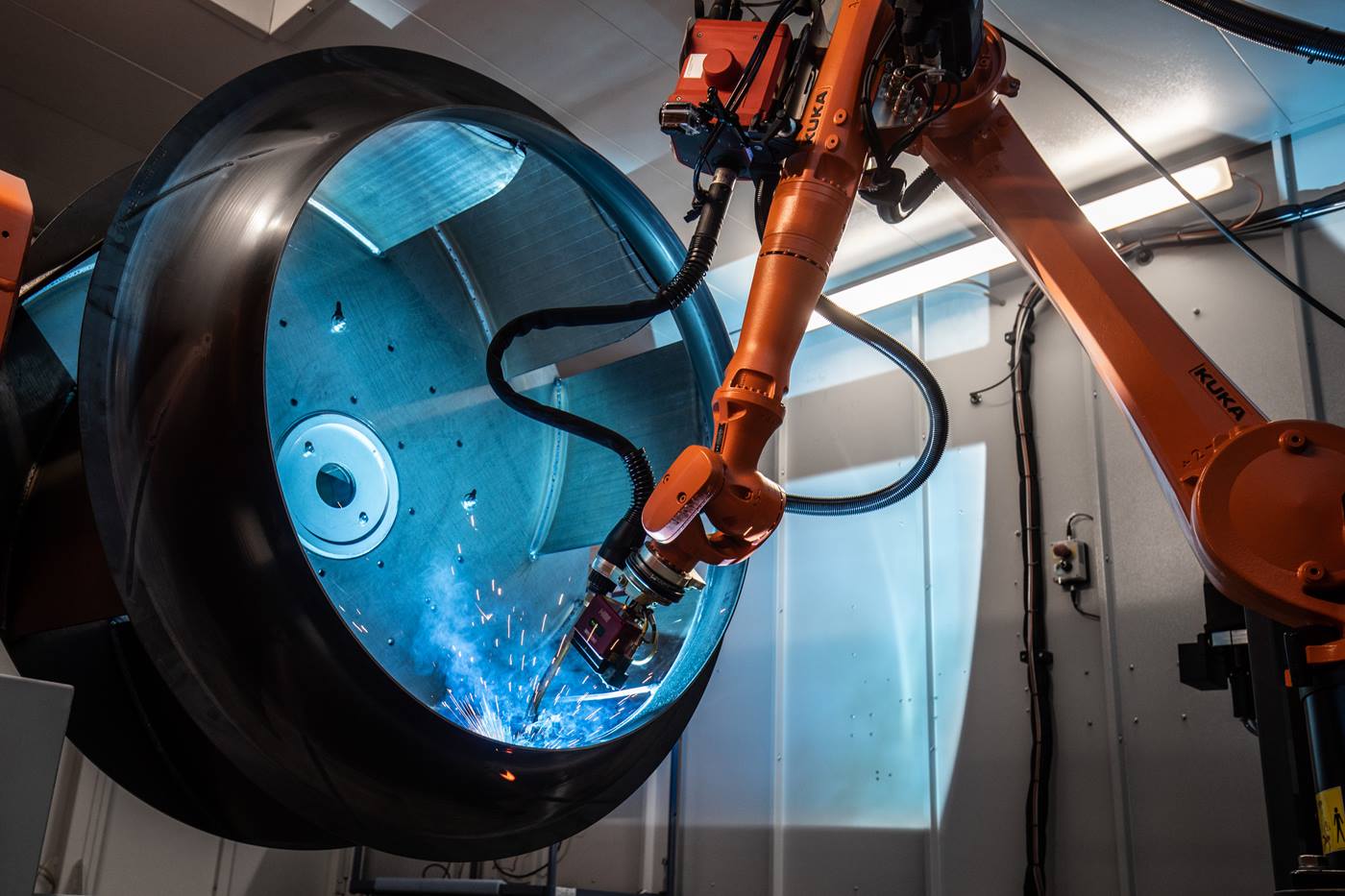

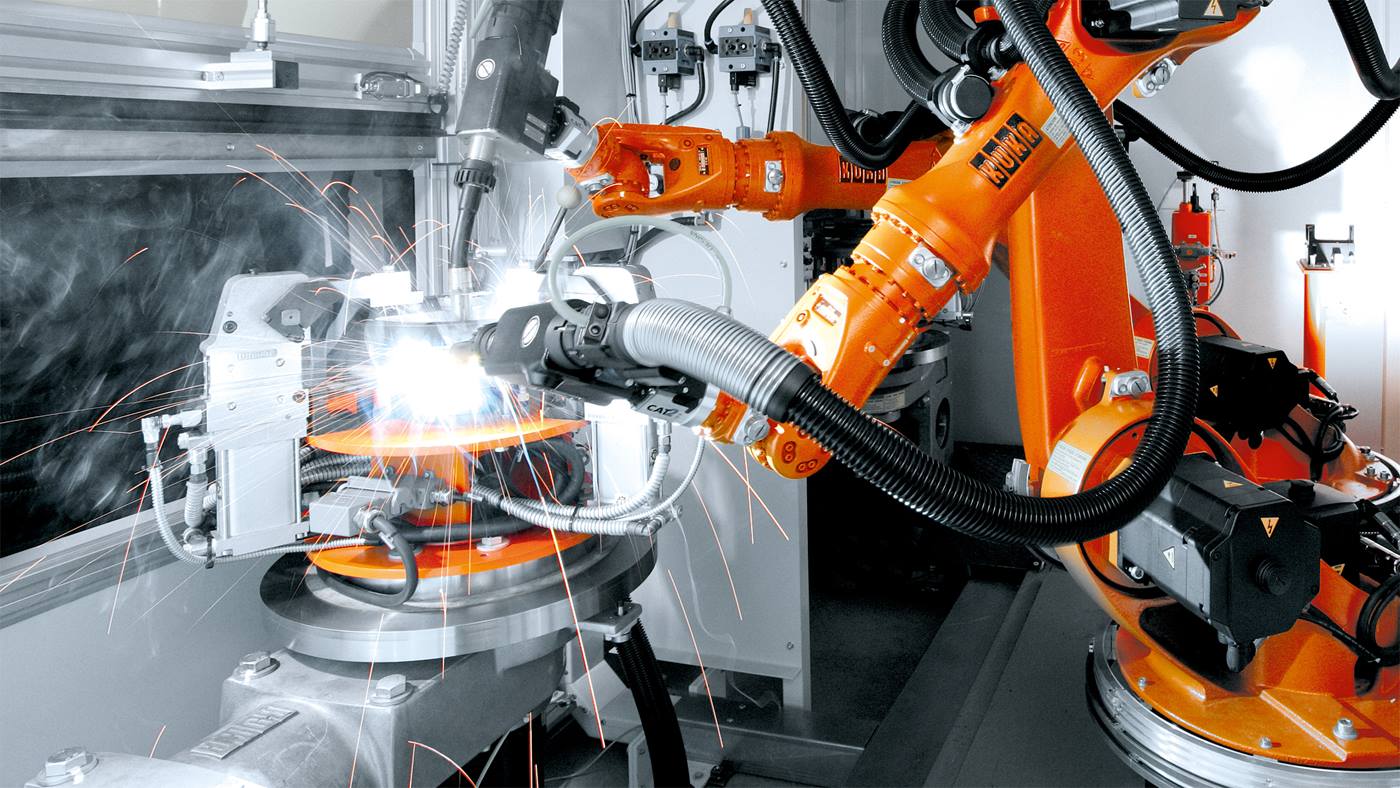

STELA designs and manufactures drying systems in all conceivable sizes and fields of application for customers from all over the world. The customers for these sys-tems come, among others, from the agricultural industry, the processing of wood materials, the food, feed, pulp and paper industries or from the water industry. At the heart of such drying plants are huge fans that set in motion a stream of warm air to remove moisture from products such as grain, corn, wood or recycled plastics. This preserves them and creates the conditions for their further processing. "The special feature at STELA is the high level of production depth," emphasizes Laxhuber. "In order to continue producing world-leading drying technology, we want to manufacture the essential components of our machines ourselves as far as possible. We see this as an essential prerequisite for the best possible quality and a long service life of the systems."