Several smart new features in KUKA.Sim 4.0- a simpler life for system integrators

Opportunity to create complete automation projects, including robot PLC and HMI, a special add-on for arc welding and that the program is now sold as an annual subscription with a very competitive price - these are some of the news when KUKA now releases version 4.0 of the simulation program KUKA.Sim.

16 August 2021

- We have refined and processed the software and have several smart news, says Micael Amandusson, channel manager at KUKA Nordic.

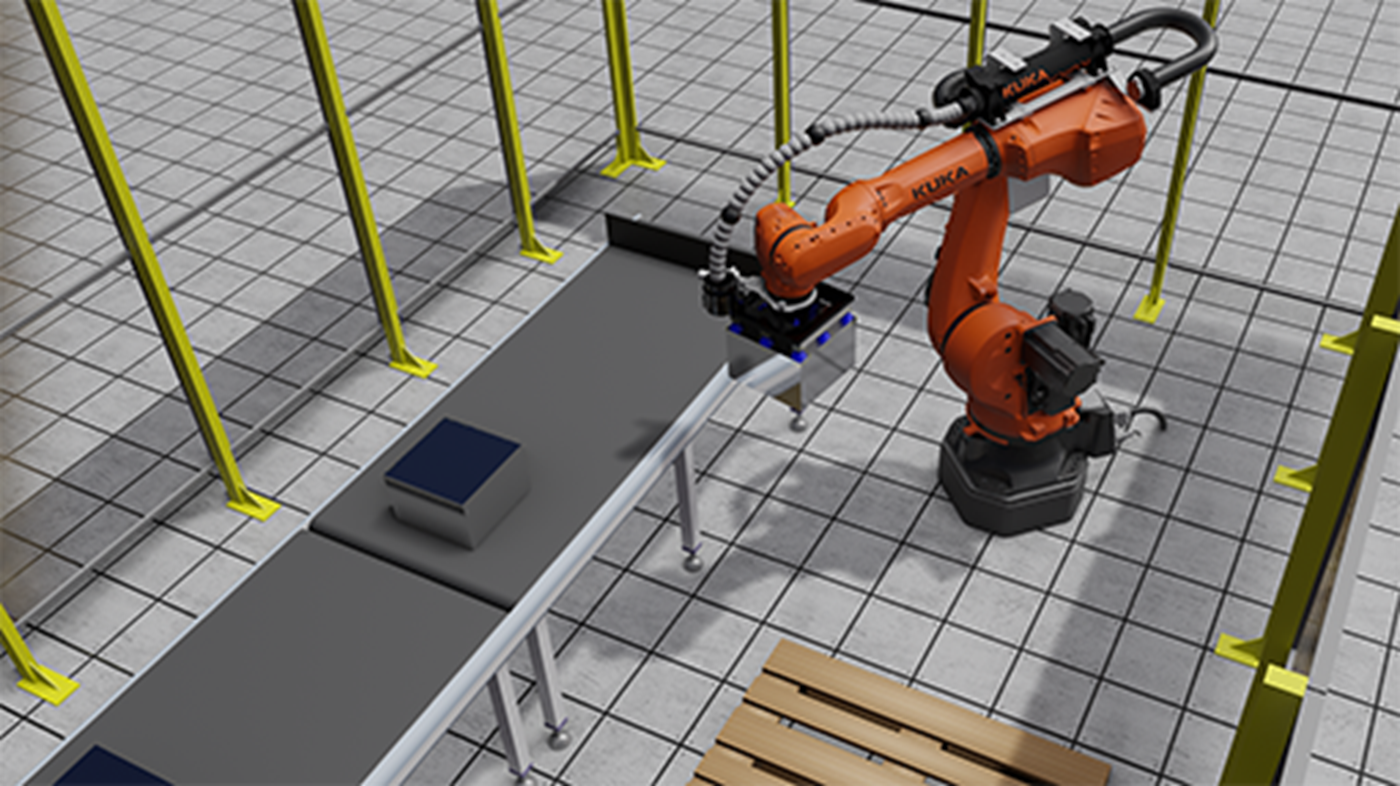

KUKA.Sim is a software that makes life easier for both system integrators and end users. When a robot cell is to be built, it is possible to perform tests and identify any weaknesses in an ordinary laptop. And it can be done with the right layout.

- The program can include a model of the environment where robots and other equipment should work and also place everything in the right scale, says Micael Amandusson.

KUKA.Sim is a software that makes life easier for both system integrators and end users. When a robot cell is to be built, it is possible to perform tests and identify any weaknesses in an ordinary laptop. And it can be done with the right layout.

- The program can include a model of the environment where robots and other equipment should work and also place everything in the right scale, says Micael Amandusson.

Load exactly the right equipment

In the new version it is also possible - with the help of an add-on to the software - to build up your own library of configurable objects with specified kinematics and so on.

- It is a big advantage, in principle you can optimize everything. You can also do things like simulate an emergency stop and see how far the robot has time to move after you press the button, and what the consequences are. All this can be done before any equipment is purchased, which saves both time and money.

- You can also export the entire configuration directly from KUKA.Sim to the robots, but we still recommend that you do it via WorkVisual, says Micael Amandusson.

According to him, the software is very user-friendly and easy to work with, much like working in Power Point, or as a kind of Minecraft for professional integrators. With the help of KUKA.Sim, it is in principle possible to go out to an end customer and demonstrate fully developed applications in their own laptop.

Saves working hours

It is also easy to make quick drafts together with the customer on site, or via an online meeting.

- In just a few minutes you can build up illustrated examples. When you then have a more finished job to show, it is easy to export a demo and send it away, says Micael Amandusson. The software is so secure that it is possible to perform a Factory Acceptance Test already at the keyboard. And in the end, all opportunities for preparatory work mean that it is possible to significantly reduce the staff needed for installation at the end customer.

In the new version it is also possible - with the help of an add-on to the software - to build up your own library of configurable objects with specified kinematics and so on.

- It is a big advantage, in principle you can optimize everything. You can also do things like simulate an emergency stop and see how far the robot has time to move after you press the button, and what the consequences are. All this can be done before any equipment is purchased, which saves both time and money.

- You can also export the entire configuration directly from KUKA.Sim to the robots, but we still recommend that you do it via WorkVisual, says Micael Amandusson.

According to him, the software is very user-friendly and easy to work with, much like working in Power Point, or as a kind of Minecraft for professional integrators. With the help of KUKA.Sim, it is in principle possible to go out to an end customer and demonstrate fully developed applications in their own laptop.

Saves working hours

It is also easy to make quick drafts together with the customer on site, or via an online meeting.

- In just a few minutes you can build up illustrated examples. When you then have a more finished job to show, it is easy to export a demo and send it away, says Micael Amandusson. The software is so secure that it is possible to perform a Factory Acceptance Test already at the keyboard. And in the end, all opportunities for preparatory work mean that it is possible to significantly reduce the staff needed for installation at the end customer.

Some news in KUKA.Sim 4.0 are:

• New KRL

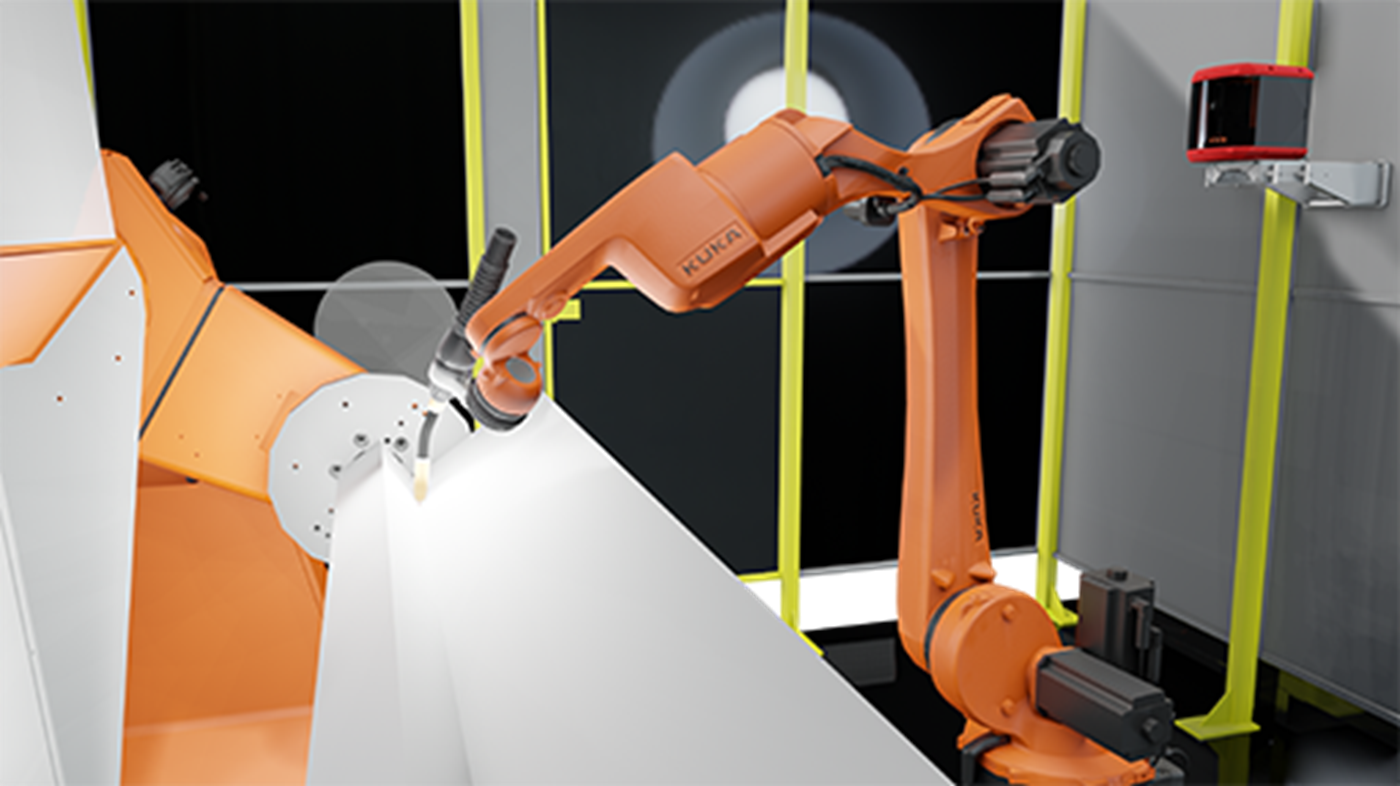

• New arc welding module

• The ability to create Work Visual objects directly in the software

• The ability to include PLC code (crucial in Virtual Commissioning)

• Sold now as an annual subscription, which means that customers do not have to make a large investment but get ROI almost immediately

• New KRL

• New arc welding module

• The ability to create Work Visual objects directly in the software

• The ability to include PLC code (crucial in Virtual Commissioning)

• Sold now as an annual subscription, which means that customers do not have to make a large investment but get ROI almost immediately

Book a review

For those who want to try the software is a 30-day trial download from KUKA Nordic's website. And if anyone wants a guide in the program's features and possibilities, Micael Amandusson and his colleagues are there to help.

For those who want to try the software is a 30-day trial download from KUKA Nordic's website. And if anyone wants a guide in the program's features and possibilities, Micael Amandusson and his colleagues are there to help.

- Just get in touch and we'll book an online meeting and go through it a little bit more thoroughly in a few hours. I like to set aside time for that, he says.