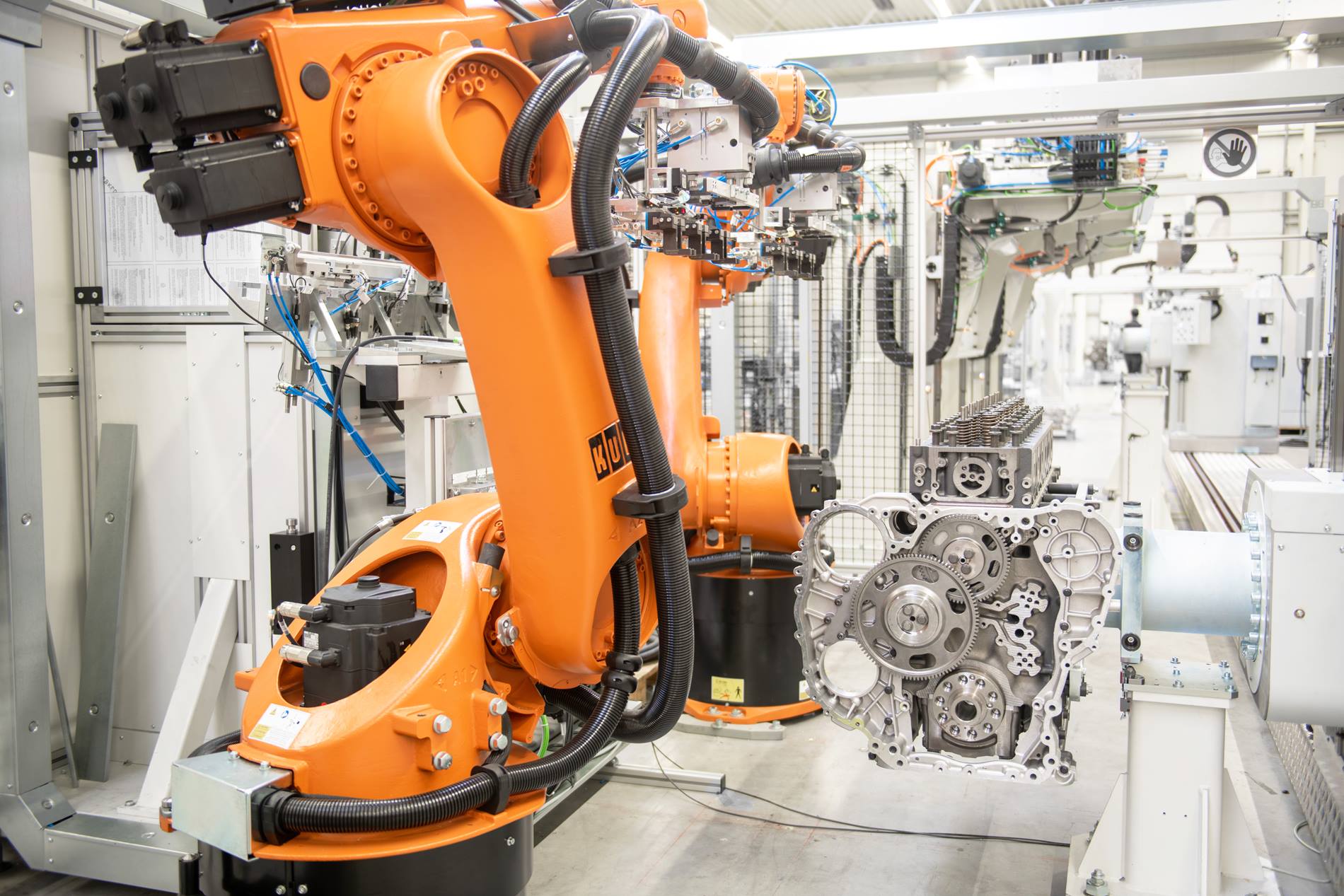

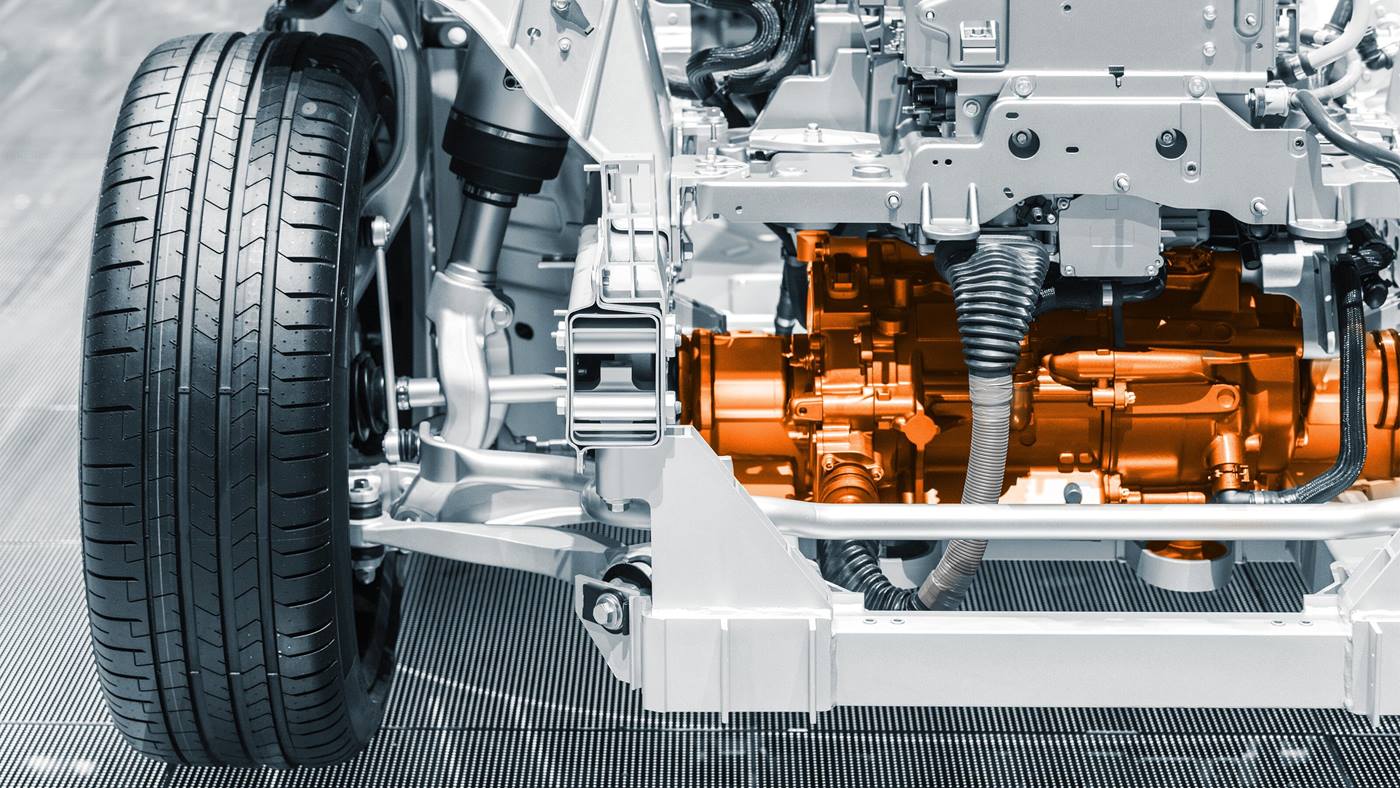

Every 110 seconds, a truck engine leaves the automated assembly line integrated by KUKA at the Scania plant

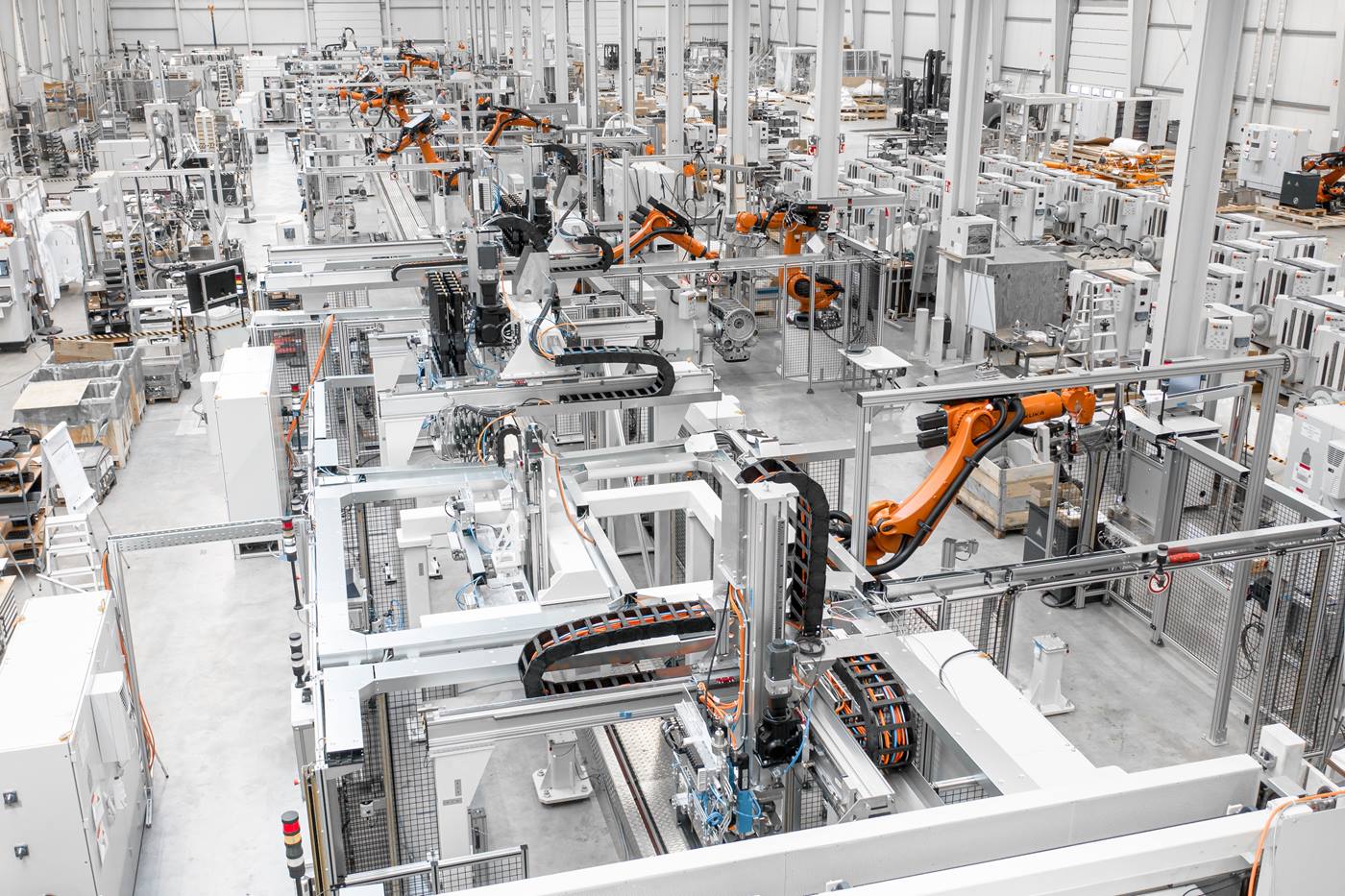

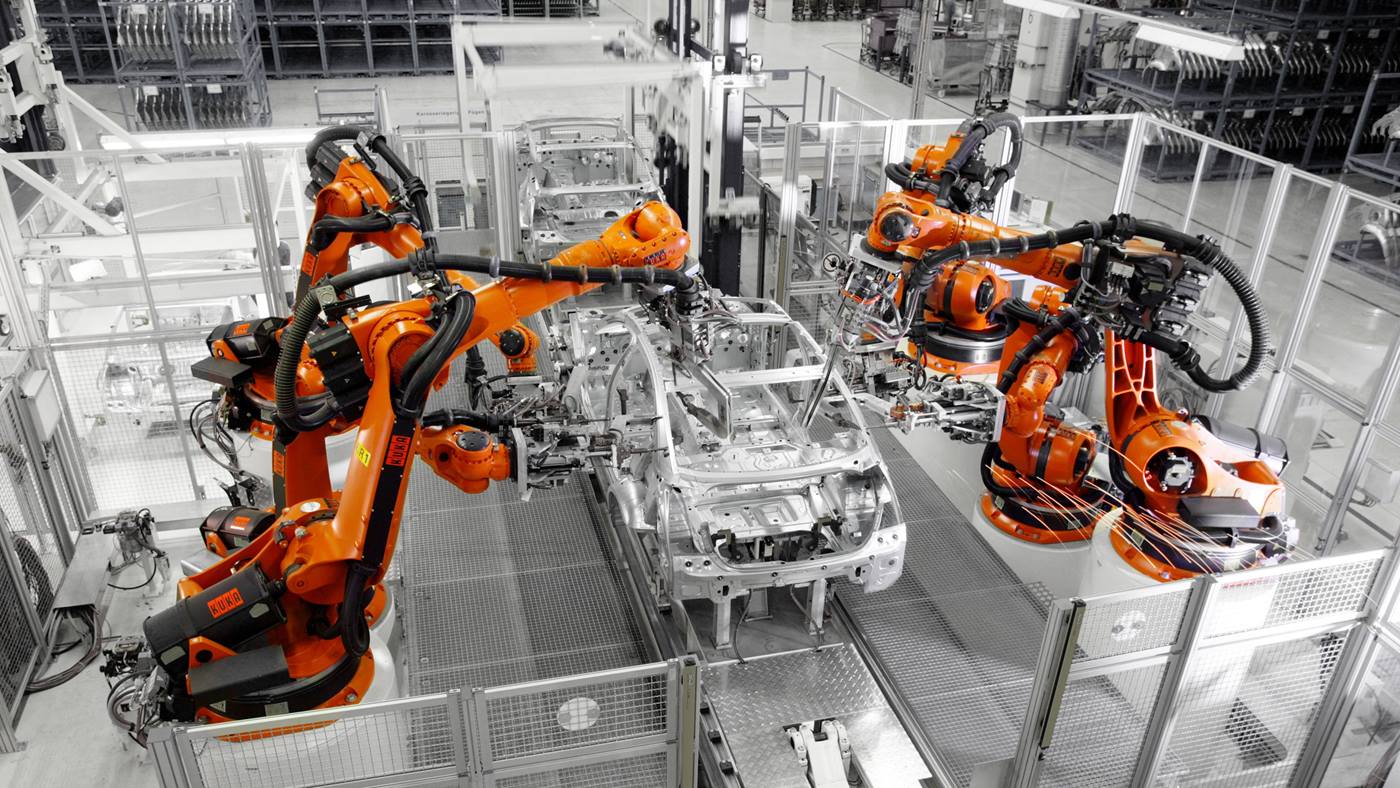

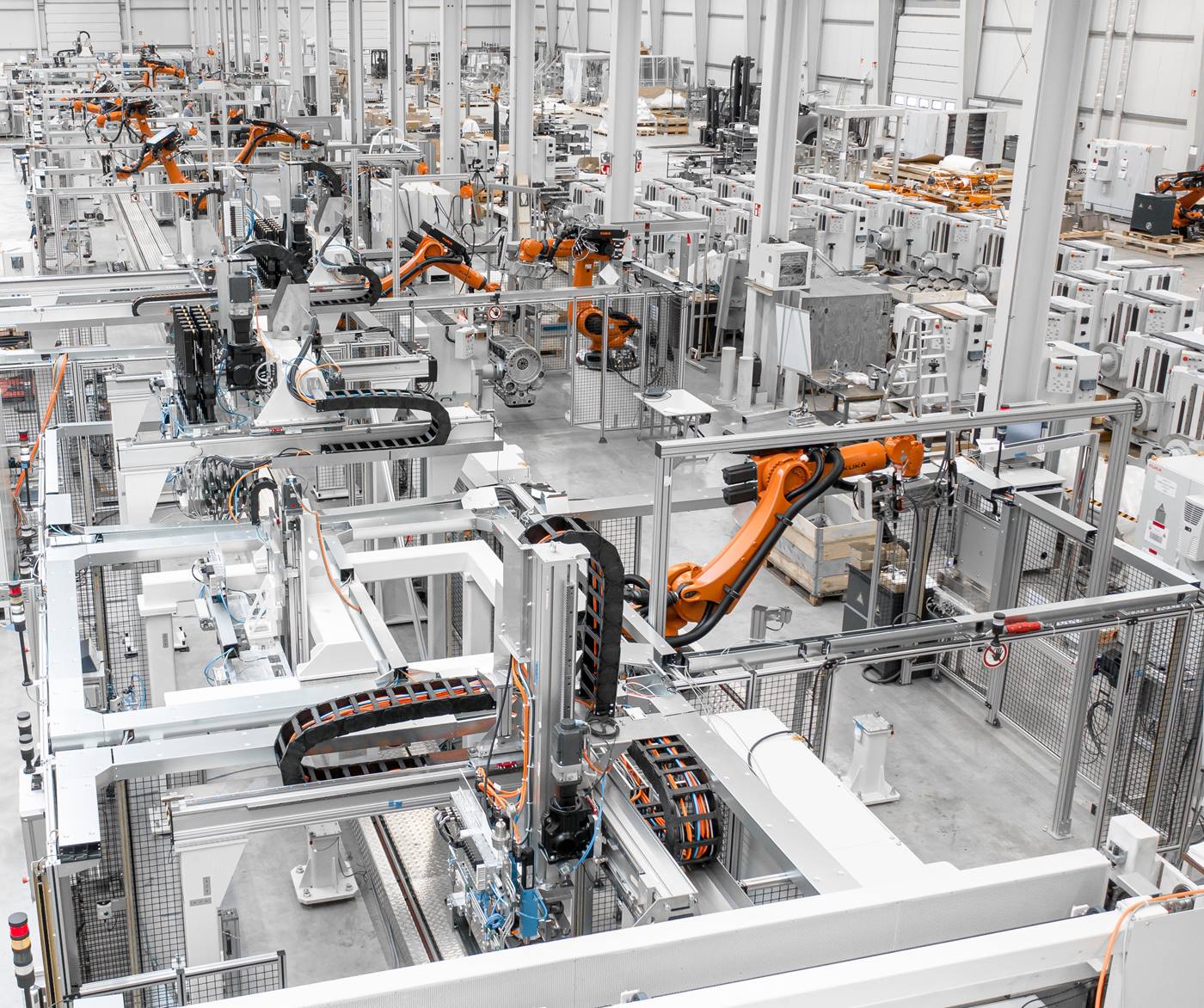

Scania’s plant headquarters in Södertälje, south of Stockholm, Sweden, covers all the build processes in commercial vehicle manufacturing, from foundry to final assembly. Together with Scania, KUKA integrated the most modern assembly line for engine blocks at this plant to date, thus laying the foundation for the new generation of commercial vehicle engines. For more than 35 years, KUKA has been successfully integrating assembly and test systems for the automotive industry on an international scale, optimizing production through efficient automation solutions.