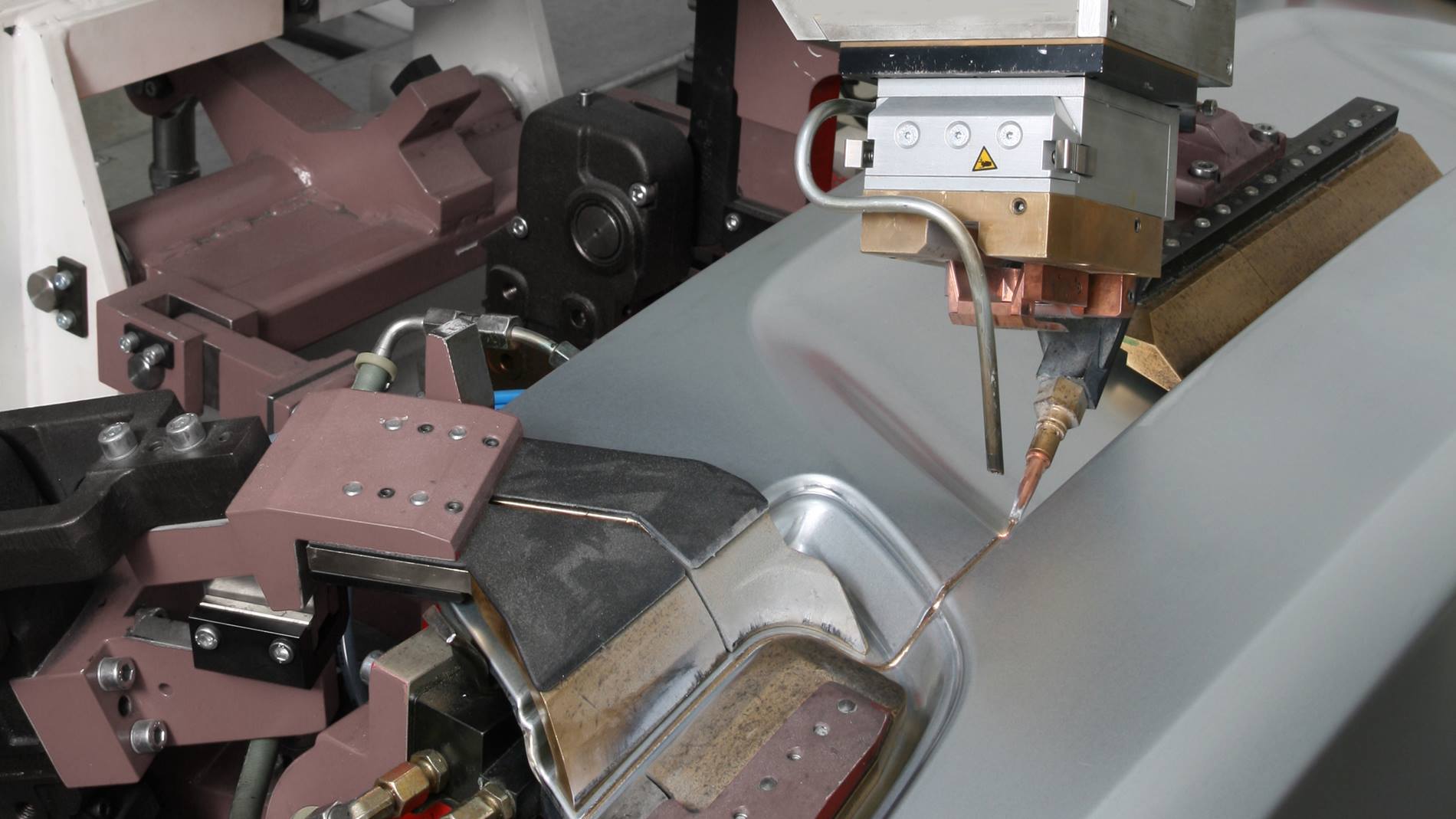

What is the technology behind the laser soldering?

Laser soldering is a non-contact process: the laser beam heats up the solder. This is then introduced to the process as a filler wire, which usually consists of copper or zinc alloys. The solder then melts and fills the joint gap. The melt fuses the two components.

The two processes of laser soldering technology:

- Hard soldering using a laser at melting temperatures above 450 °C:

This joining technique uses diode lasers with higher power and is used primarily in the automotive industry. - Soft-soldering using a laser at melting temperatures below 450 °C:

This technique is commonly used in the manufacture of electronic components.

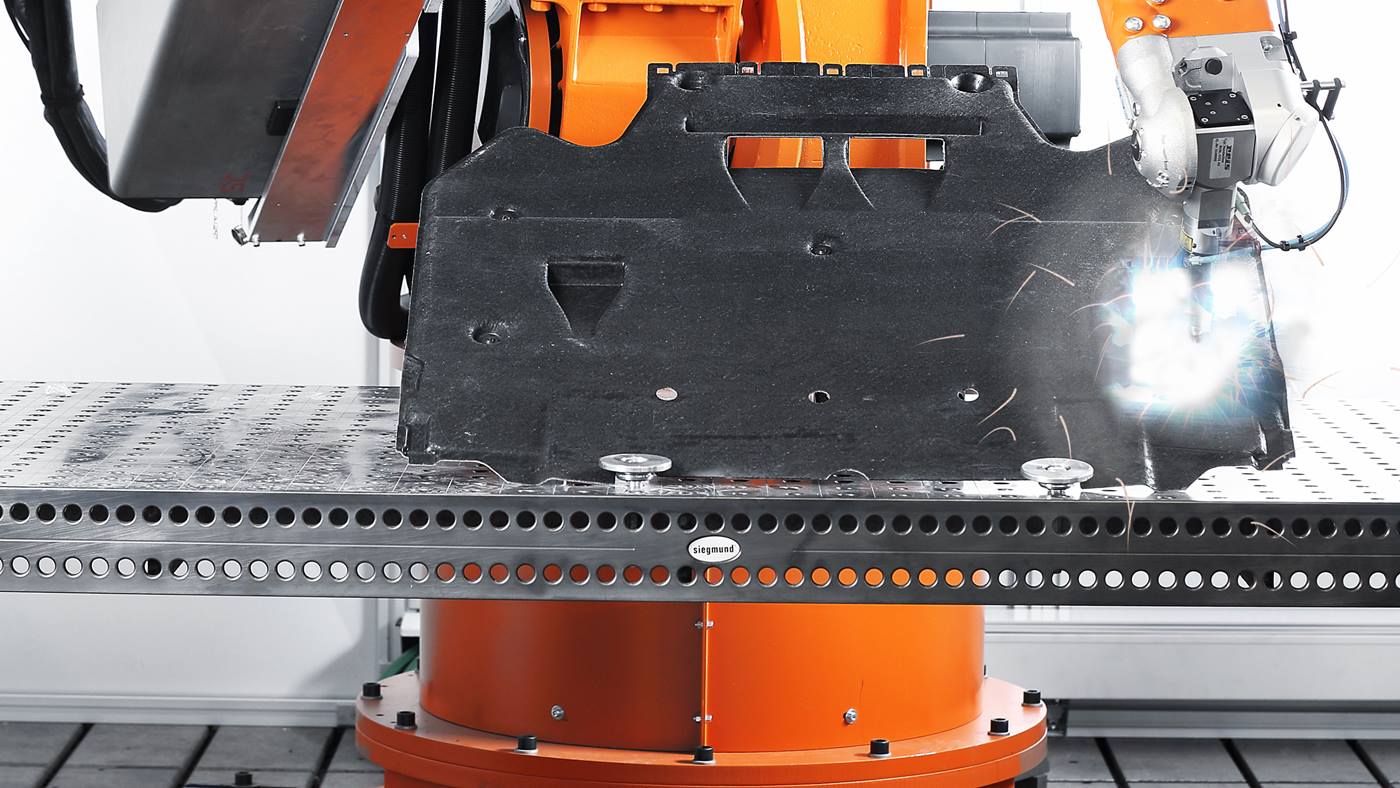

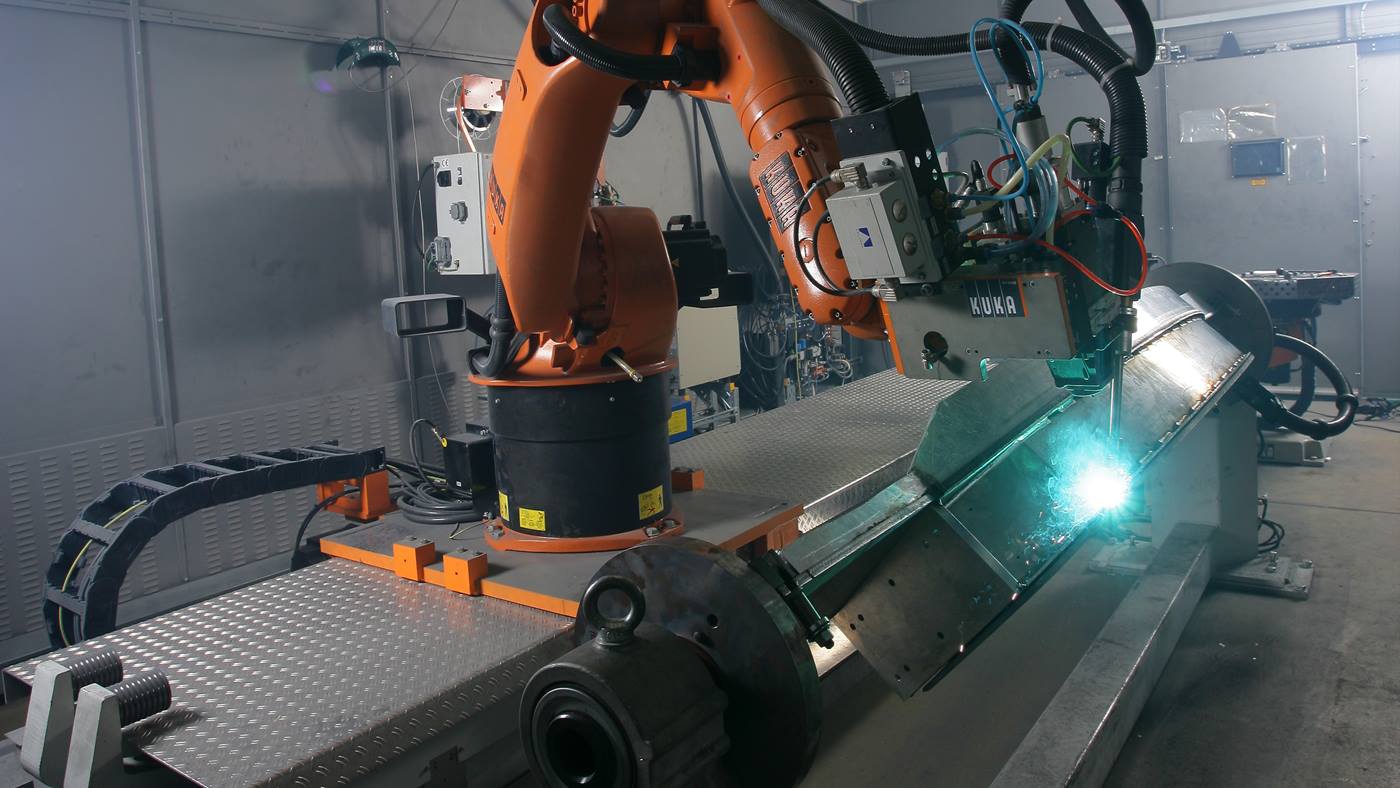

Automated laser soldering

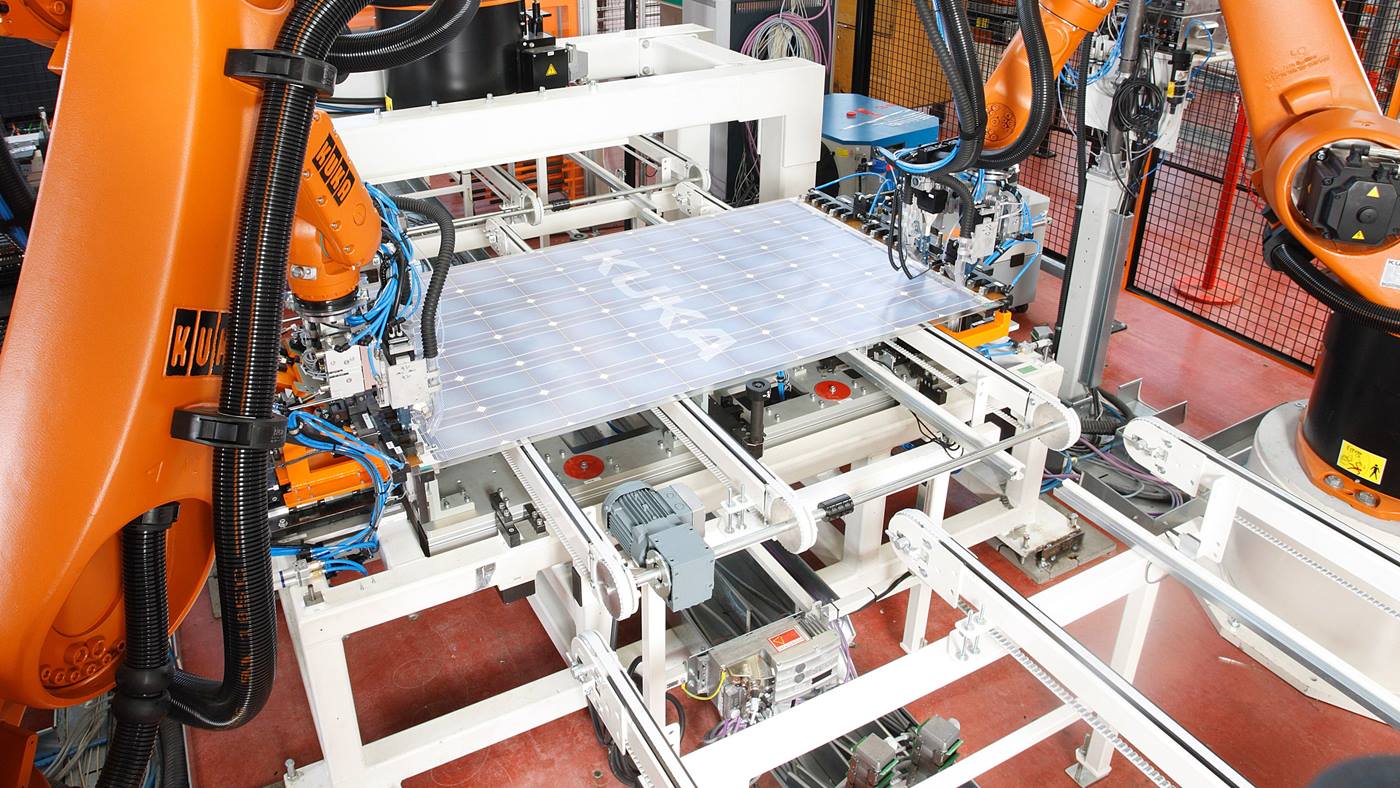

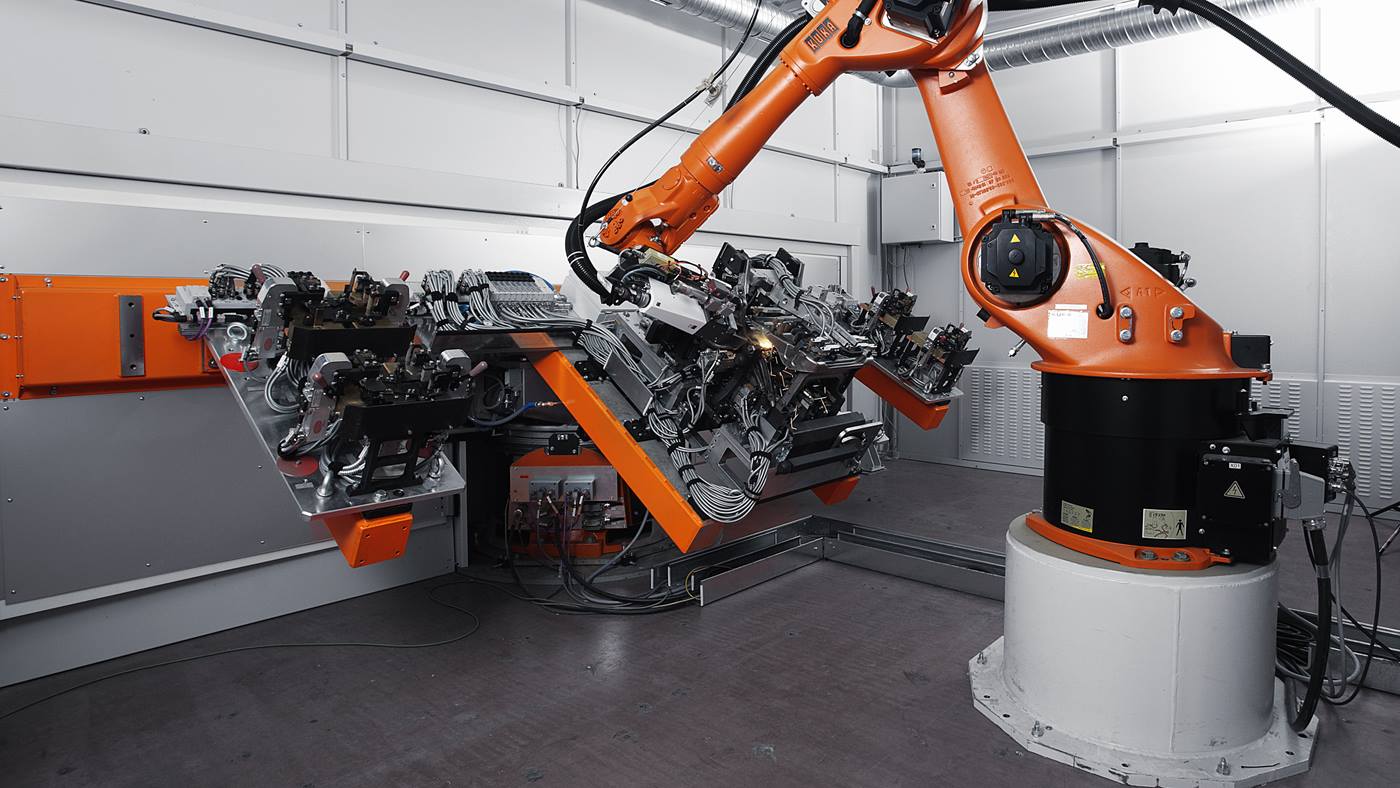

As a KUKA customer, you have two options:

- Automated and scalable production systems

- Individually configured manufacturing cells

Parameters such as path velocity, laser power or optimum wire feed are second nature to us, and we offer various technology packages for different production scenarios.

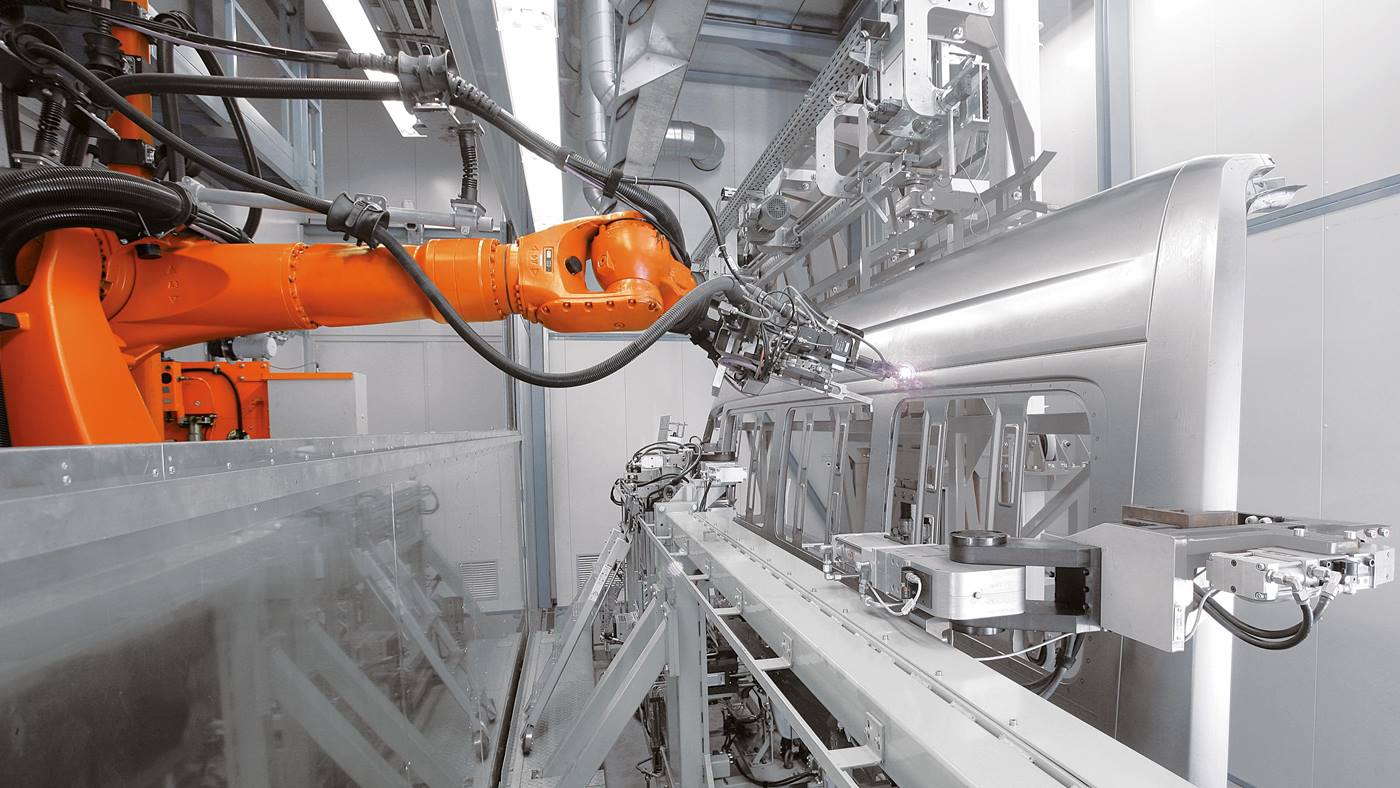

Aluminium and aluminium alloys play an important role in e-mobility because of the ideal combination of lightness and strength. In welding and joining processes, aluminium has high demands on the processes used. With comprehensive process know-how and the right

products, we make you fit for the technological transformation towards e-mobility. The example of the battery box shows how robots enable the production of aluminium components at the highest quality level;

Read what is important for aluminium welding in electromobility.

Download e-book

Software to automate your soldering tasks

With our modular software solutions, you can carry out intelligent robot-based soldering processes using lasers and thus increase your production. The aim is to reliably monitor all parameters through ideal communication between the soldering equipment and the robot controller.

With KUKA, laser applications mean automation, accuracy and significant process improvement.

Find more details about our laser technologies in the brochure.

Download here