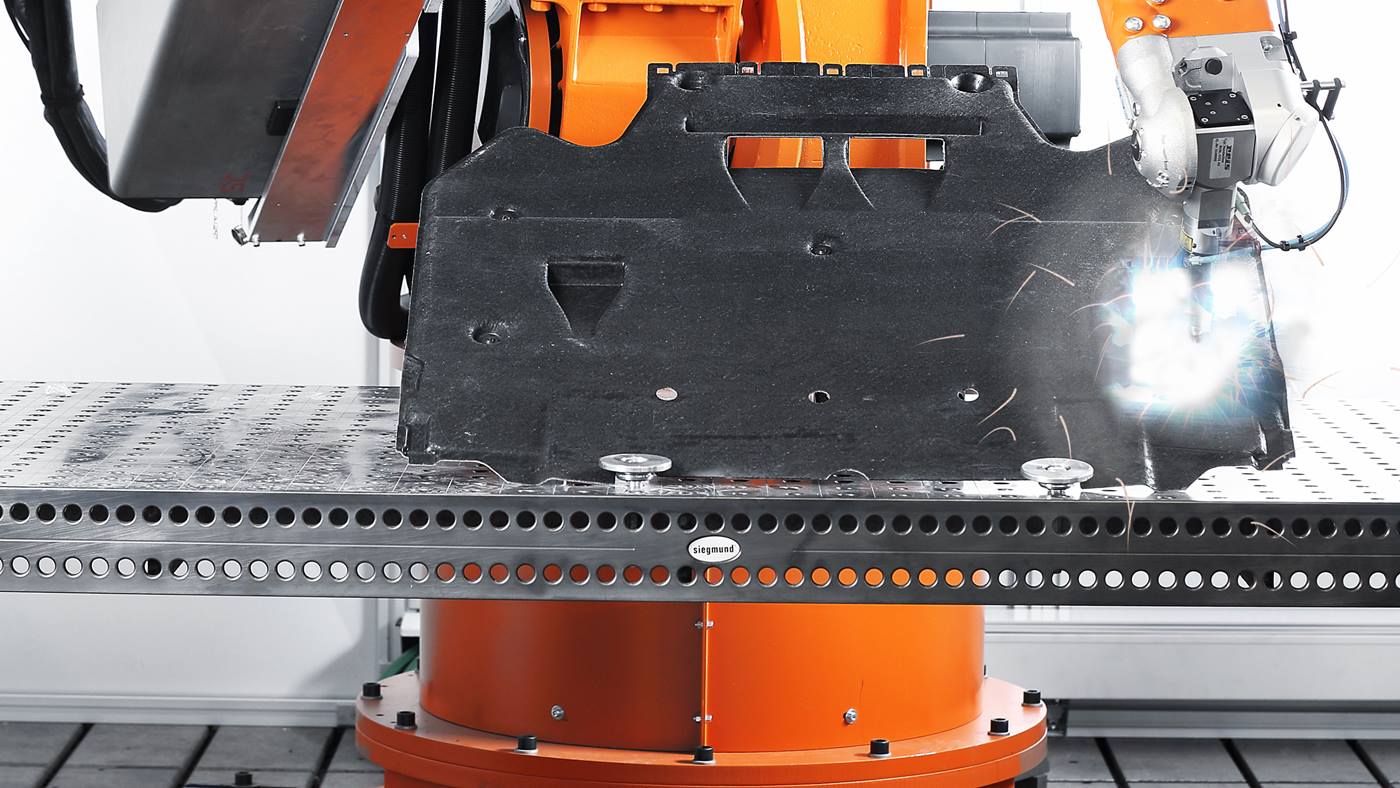

Automated oxyacetylene cutting

With automated oxyacetylene cutting, the results are reproducible. The proven torch technology and the automatic ignition device ensure that the process starts smoothly. Safe flame monitoring and automatic hole cutting mean that no preparation is required.

Automated oxyacetylene cutting is a proven technology wherever steel in different thicknesses needs to be cut accurately and efficiently. When implementing this process, we rely on our technology database. All of our know-how from past projects regarding materials, sheet thicknesses, seam shapes, and cutting speeds are stored here.