KR 500 FORTEC

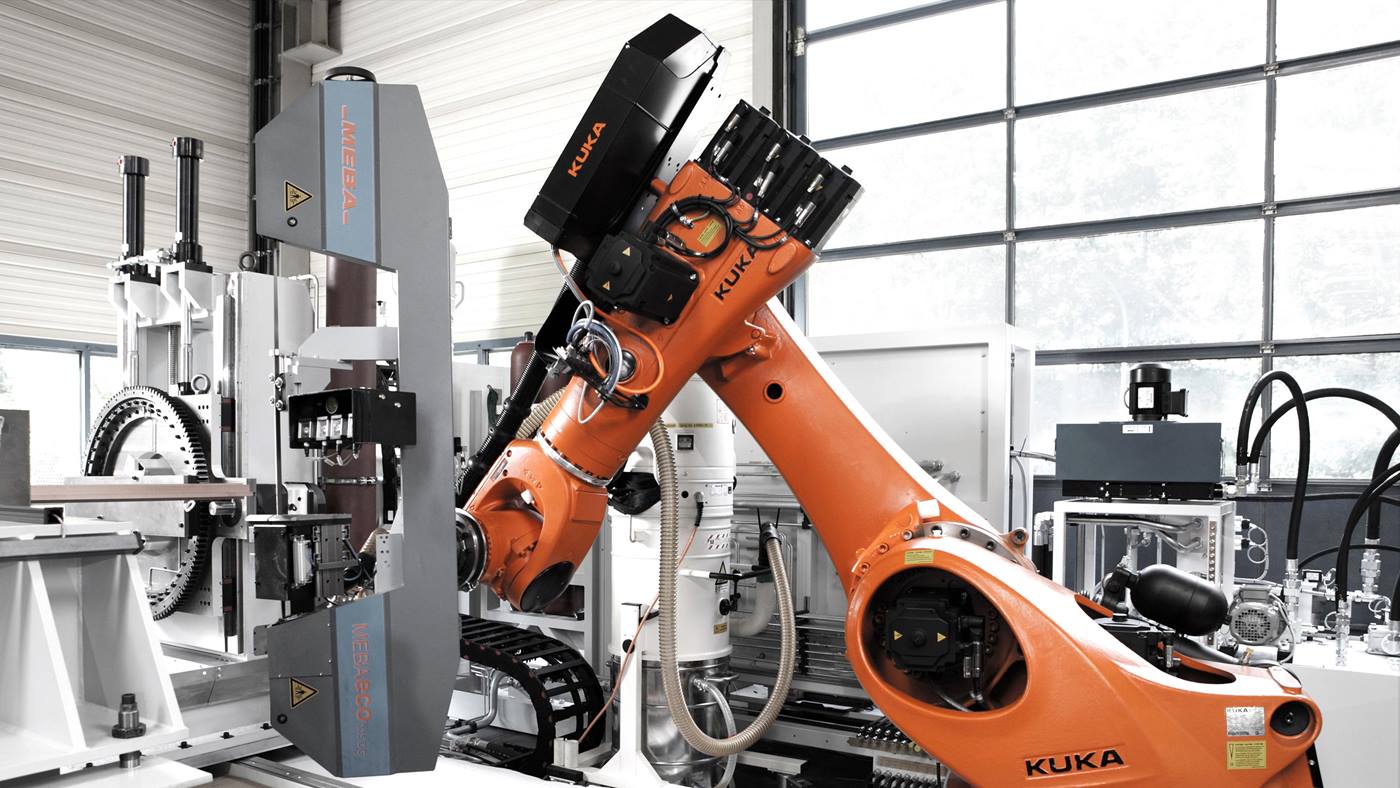

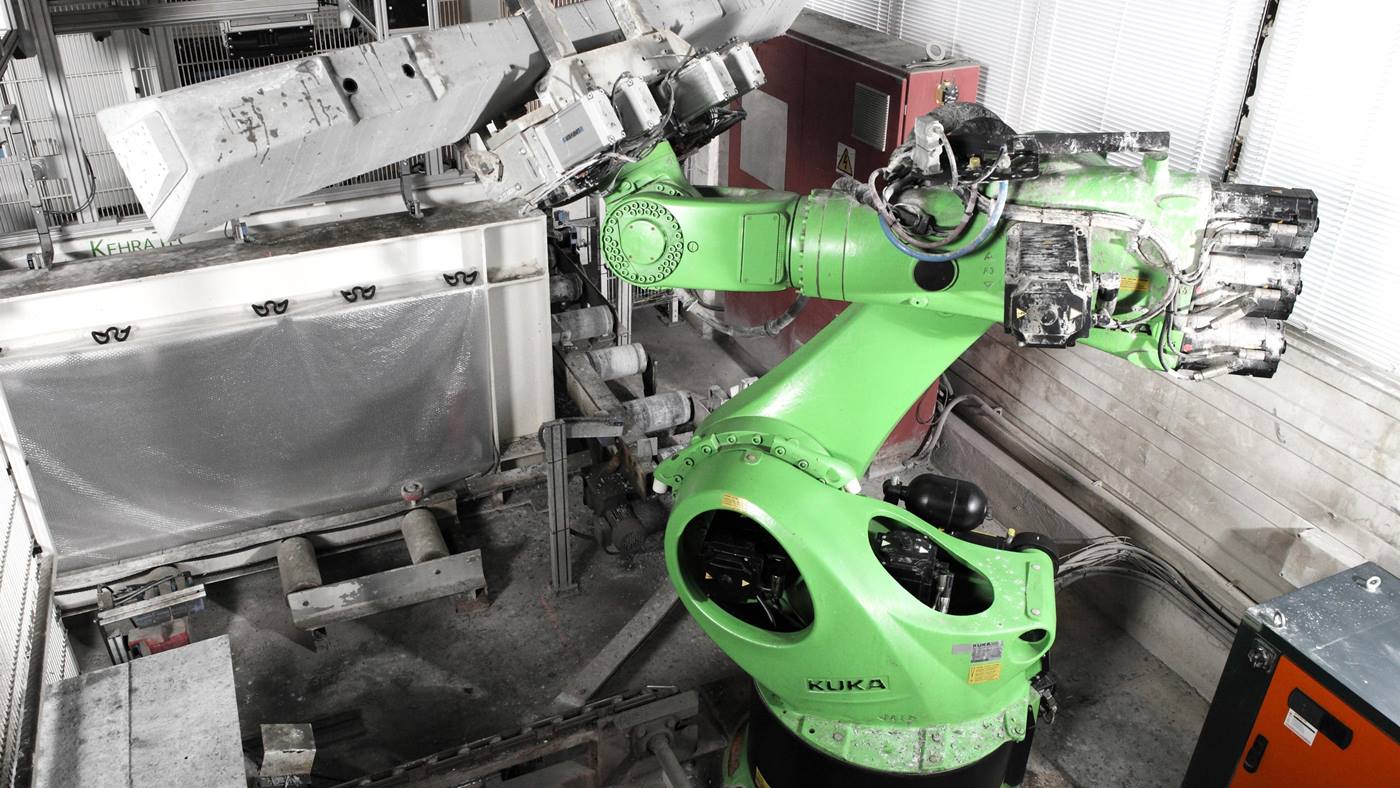

The KR 500 FORTEC is our versatile heavy-duty robot that is suitable for a wide range of applications. For example, the Machine Tool variant is predestined for milling applications in the high payload range, while the Foundry variant is perfectly suited to heavy-duty tasks in the foundry.

The exceptional product quality that the KR 500 FORTEC delivers in milling and other applications is based on two fundamental features that inspired the robot’s name: strength and proven technology. Reaches of up to 3,326 millimeters enable large workpieces to be processed, even in confined cells. Thanks to its streamlined design with minimized interference contours, the robot provides you with an unusually large workspace and the maximum possible payload distances.

KR 500 FORTEC (6 axes) - technical data

Robots

Total load

Maximum reach

Version environment

Downloads

KR 340 R3330

Total load

340 kg

Maximum reach

3326 mm

Version environment

Standard

Downloads

- Total load 340 kg

- Maximum reach 3326 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Floor

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 340 R3330 F

Total load

340 kg

Maximum reach

3326 mm

Version environment

Foundry

Downloads

- Total load 340 kg

- Maximum reach 3326 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 420 R3080

Total load

420 kg

Maximum reach

3076 mm

Version environment

Standard

Downloads

- Total load 420 kg

- Maximum reach 3076 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Floor

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 420 R3080 F

Total load

420 kg

Maximum reach

3076 mm

Version environment

Foundry

Downloads

- Total load 420 kg

- Maximum reach 3076 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 420 R3330 F

Total load

420 kg

Maximum reach

3326 mm

Version environment

Foundry

Downloads

- Total load 420 kg

- Maximum reach 3326 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 500 R2830

Total load

500 kg

Maximum reach

2826 mm

Version environment

Standard

Downloads

- Total load 500 kg

- Maximum reach 2826 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Floor

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 500 R2830 C

Total load

500 kg

Maximum reach

2485 mm

Version environment

Standard

Downloads

- Total load 500 kg

- Maximum reach 2485 mm

- Construction type Standard

- Version environment Standard

- Mounting positions Ceiling

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 500 R2830 C-F

Total load

500 kg

Maximum reach

2485 mm

Version environment

Foundry

Downloads

- Total load 500 kg

- Maximum reach 2485 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Ceiling

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 500 R2830 F

Total load

500 kg

Maximum reach

2826 mm

Version environment

Foundry

Downloads

- Total load 500 kg

- Maximum reach 2826 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 500 R2830 MT

Total load

500 kg

Maximum reach

2826 mm

Version environment

Standard

Downloads

- Total load 500 kg

- Maximum reach 2826 mm

- Construction type Machine Tooling

- Version environment Standard

- Mounting positions Floor

- Protection class IP 65

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 500 R2830 MT-F

Total load

500 kg

Maximum reach

2826 mm

Version environment

Foundry

Downloads

- Total load 500 kg

- Maximum reach 2826 mm

- Construction type Machine Tooling

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 510 R3080 F

Total load

510 kg

Maximum reach

3076 mm

Version environment

Foundry

Downloads

- Total load 510 kg

- Maximum reach 3076 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

KR 600 R2830 F

Total load

600 kg

Maximum reach

2826 mm

Version environment

Foundry

Downloads

- Total load 600 kg

- Maximum reach 2826 mm

- Construction type Standard

- Version environment Foundry

- Mounting positions Floor

- Protection class IP 65, IP 67

- Downloads Download Center

- Controller

- Learn more KUKA Marketplace

%x of %y robots visible