SMARTHANDLE

Within the EU-funded project SMARTHANDLE (2023-2025) KUKA is working on enhancement of the productivity, flexibility and sustainability of the handling operations together with research and industrial institutions from Greece, Spain, Netherlands, Luxemburg, and Belgium.

The aim of the project is to develop technologies that can support the European industry, e.g.:

-

intelligent reconfigurable agents providing flexibility and dexterity for handling applications

-

AI-based reasoning enablers to enhance the adaptability and efficiency of handling processes

-

high-level planning and coordination mechanism for successful deployment in real life use-cases

In this project, the KUKA TIC team will tackle different challenges, e.g., how to control a multi-arm robotics system considering geometrical constraints or how to plan a motion without losing a grasped object.

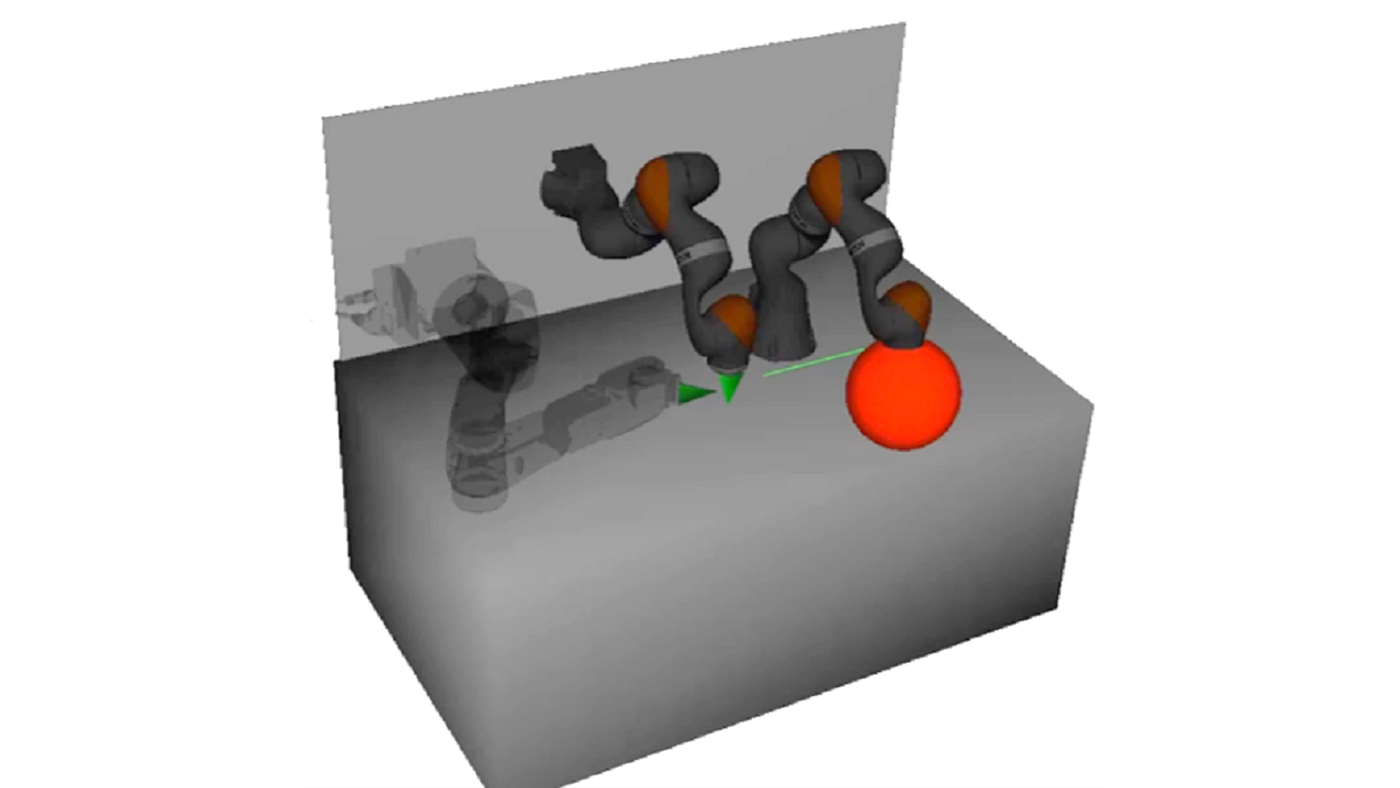

Multi-arm robot planning

We are working on the development of the novel motion algorithms to plan and execute industrial tasks on single- and multi-arm robot systems. Based on task descriptions, which combine CAD data and geometric constraints, our algorithms can calculate feasible motions through exploiting robot and process redundancies. In this sense, since the geometric constraints are imposed in closed loops on different systems, classical position control strategies may fail to deliver feasible solutions, that satisfy the prerequisites of the systems, and subsequently they fail to meet the safety requirements. Hence new methods based on the combination of position, force, and impedance control for multi-arm system will be developed. These control systems should receive not only stand-alone inputs from the process planner, but also feedback from their robotic counterparts. The development and the global implementation of this control architecture will be the focus of the multi-arm robot planning.

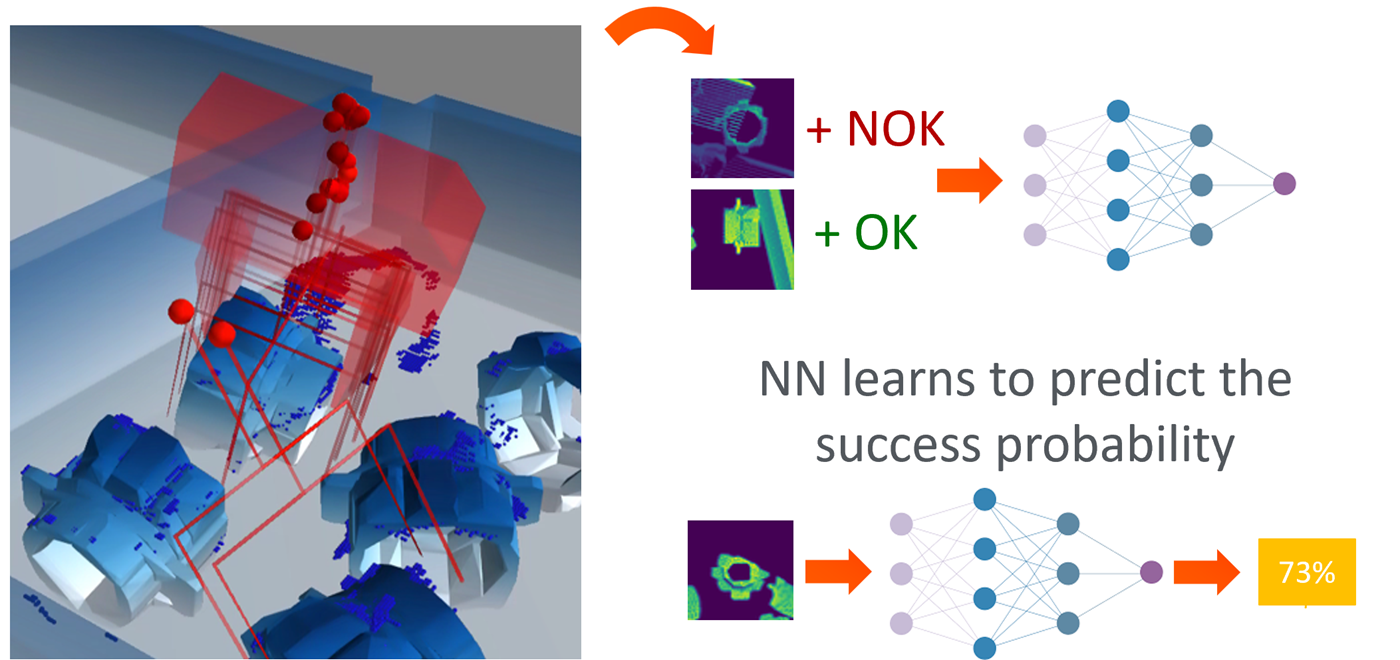

AI-based grasping

To grasp known and unknown workpieces we will adapt and extend existing learning-based grasping techniques, especially by advancing them from single-arm grasping to dual-arm grasping. With these techniques feasible grasps are determined by scoring them according to their grasp success probability.

The technologies developed by KUKA will be evaluated and validated in two industrial real-life scenarios. The first scenario, proposed by Greek aluminum products manufacturer ALUMIL, refers to the handling and transportation of bulky workpieces such as aluminum profiles. The second scenario, proposed by Belgian automotive tier-one supplier ABEE, concerns the disassembly of car batteries.