Your project, our professional approach

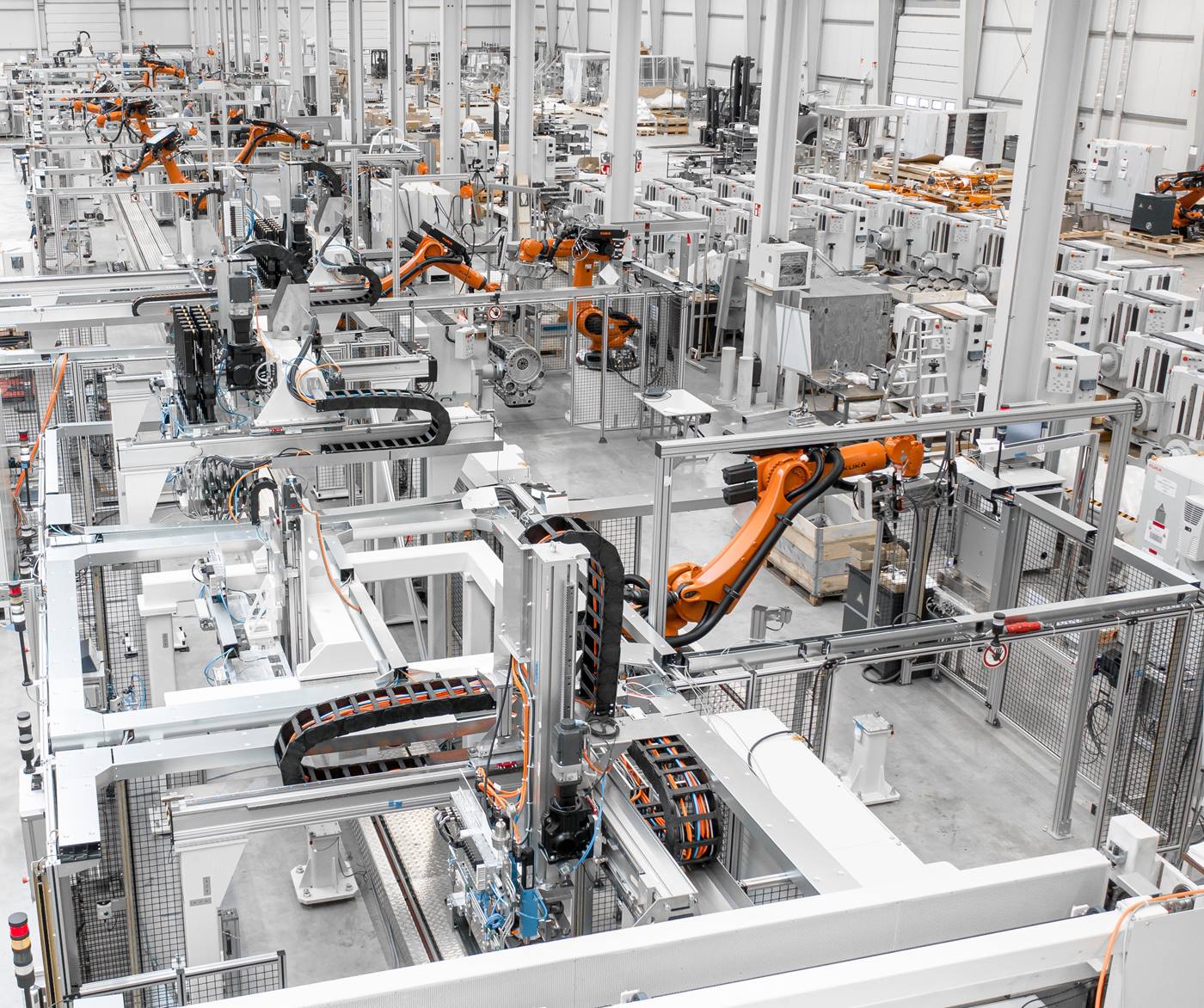

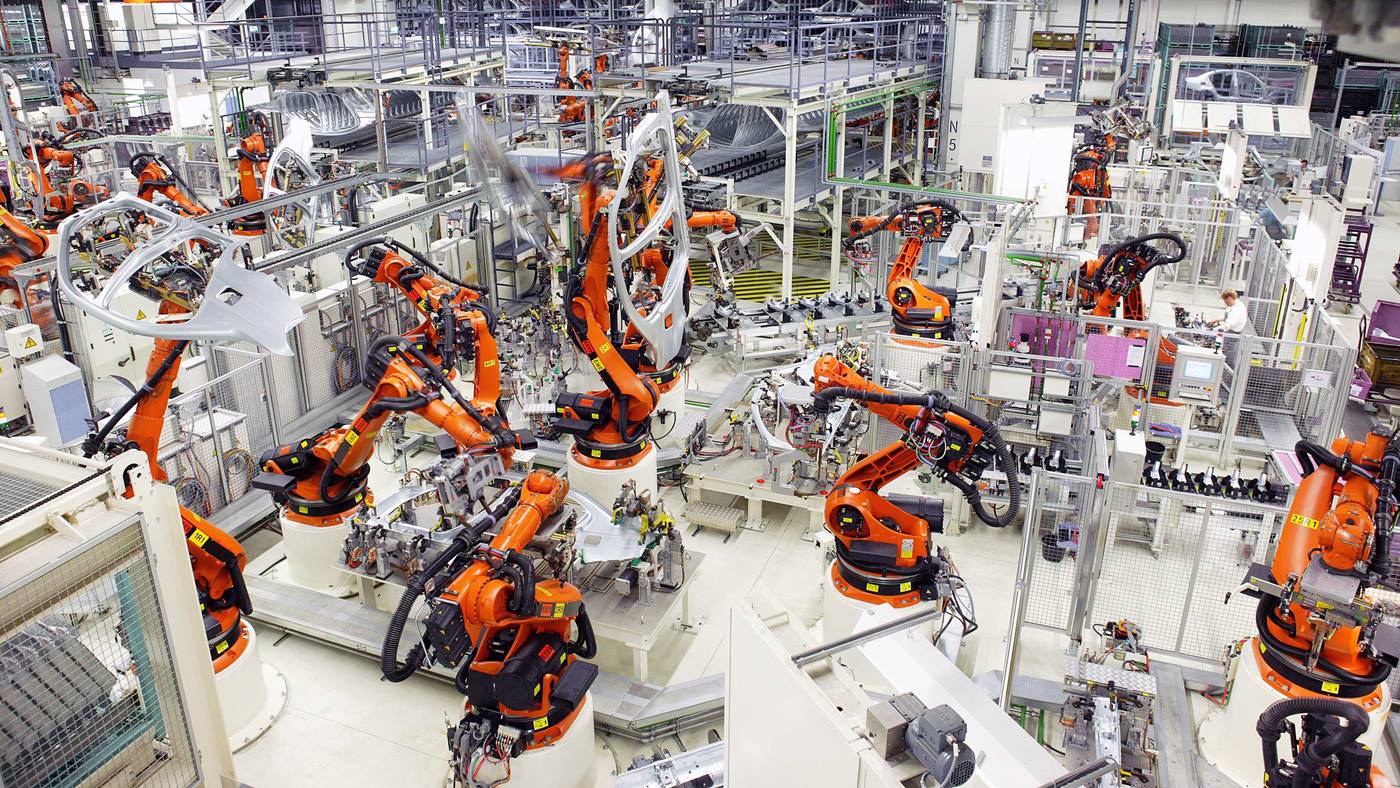

KUKA Slovakia is your reliable partner when it comes to developing, planning and designing modern production systems. With around 30 years of experience in automation solutions and being part of the global KUKA network, we are able to offer comprehensive solutions in various industrial sectors that streamline, safeguard and future-proof your production processes.

Project management

Efficient project management is the key to successful automation projects. We coordinate the development and optimization of fully and partially automated production lines.

Our project management services

- Development and integration of new systems

- Support with technical product development and design optimization in conjunction with customer design teams

- Structured project planning and schedule monitoring

- Regular project checks and progress analysis

- Implementation of automation solutions on site

Business development and process optimization

- Identification of potential for increasing efficiency

- Development of customized concepts for production optimization

- Optimization of partially and fully automated manufacturing processes

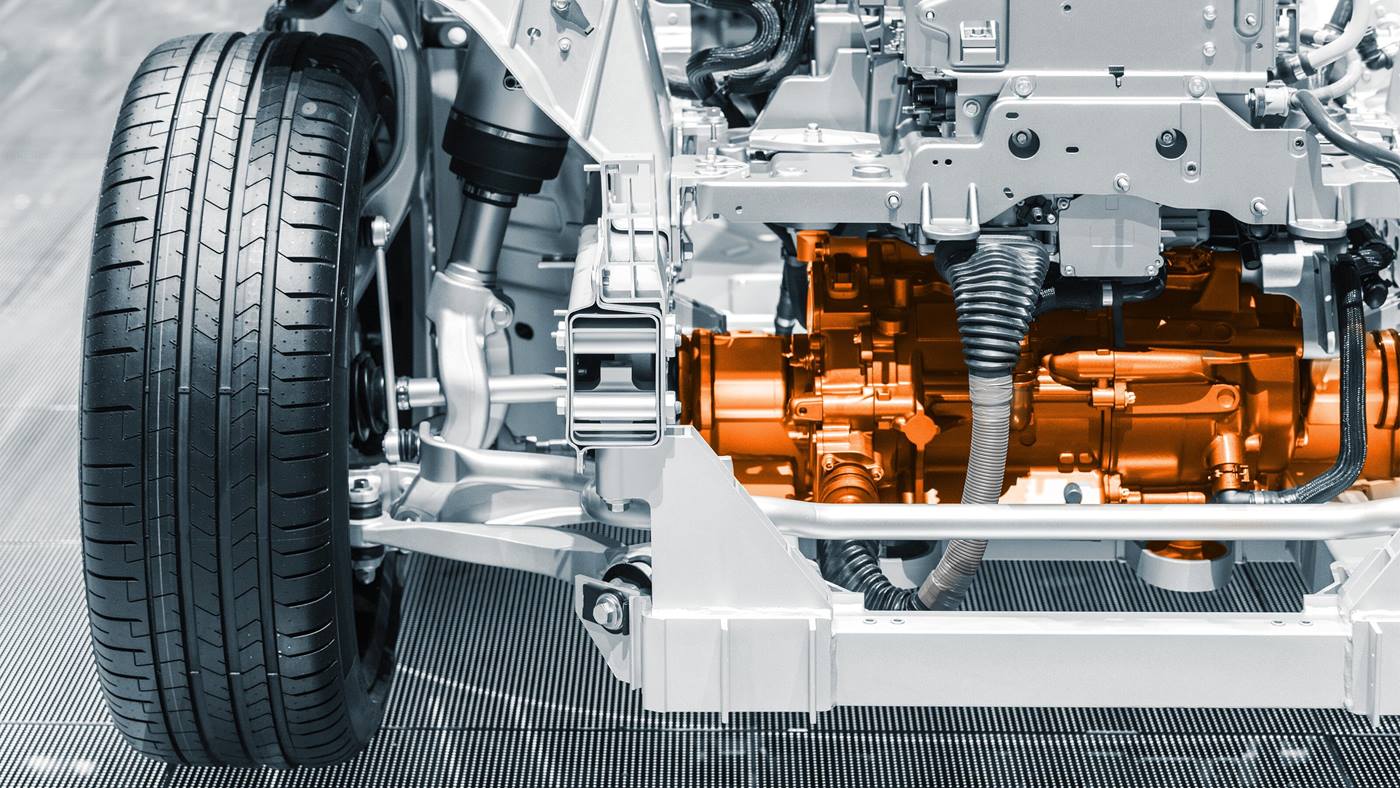

Design of robot fixtures and manufacturing systems

Our design experts develop complex fixtures for robot lines, focusing on simple, cost-efficient and maintenance-friendly solutions.

Design of fixtures for robot lines

- Automatic and manual clamping fixtures

- Assembly systems for various products

- Conveyor systems and material flow solutions

- 3D/2D design and parts lists

Analysis and optimization

- Cycle time analysis and process evaluation

- Selection of suitable purchased components

- Determination of suitable robot systems

- Feasibility and accessibility studies

We use powerful CAD software such as DS Catia, SolidWorks, and Siemens NX.

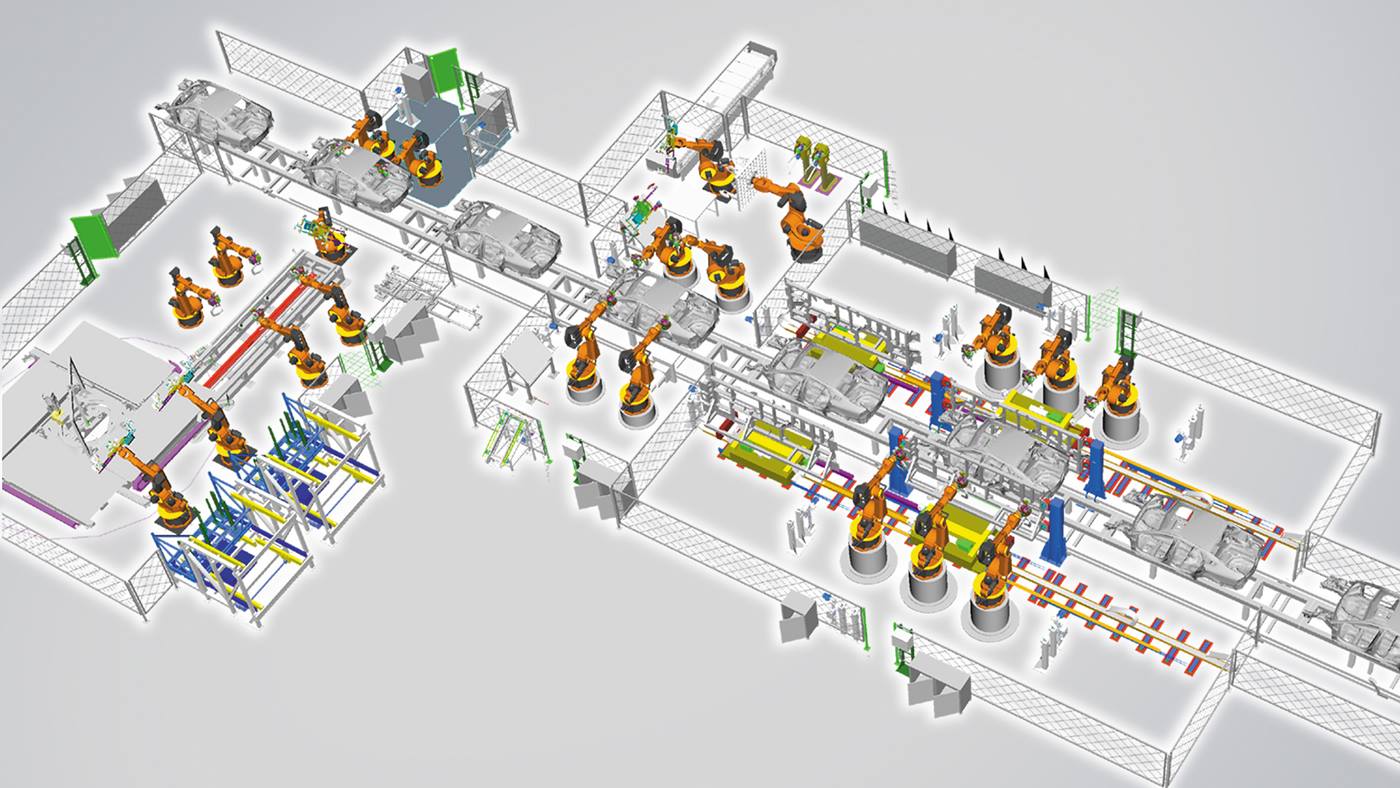

Process simulation and offline programming for robots

We test production processes and develop robotic cells and manual workstations according to customer-specific requirements, always with a focus on maximum efficiency, productivity, and ergonomics.

Our simulation and offline programming expertise

- Creation of OLP programs for ABB, FANUC and KUKA robots

- Load data analysis

- Optimization of individual programs

- Optimization of cycle times

- Documentation for robot programs and production lines

Concept development for robot lines

- Feasibility studies

- Process planning

- Ergonomic analyses

- MTM analyses for manual workstations

- Cycle time analysis

- Layout planning including complex elaboration of production processes

Tools used: KUKA.Sim, DS Delmia, Process Designer and additional industry-specific software solutions.

Electrical design for automation technology

Technical documentation

We will prepare comprehensive technical documentation for you in accordance with applicable European directives and standards (2006/42/EC) as well as your specific requirements.

Documentation

-

Provision of multilingual documentation in cooperation with certified translation agencies

-

Creation of mechanical parts lists, spare parts and wearing parts lists

-

Creation of 3D/2D layouts and foundation plans in Microstation and AutoCAD

-

Risk and safety analyses of systems (Safexpert)

-

Development of applications and tools for efficient work processes

Documentation is typically created in Office 365, managed in the PLM system, Teamcenter, or our in-house development program, KUKA PDM, and also incorporated it into your customer-specific systems and databases.