Set it up, switch it on, get started._It’s iisy

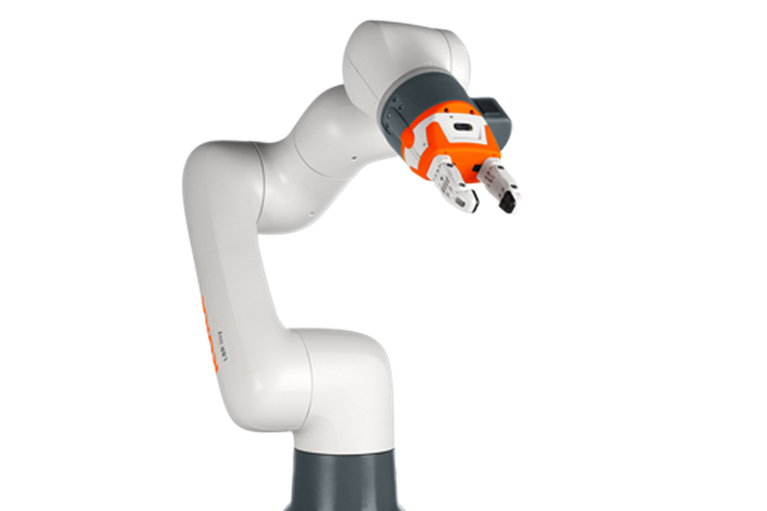

Ready for use in just a few minutes – the LBR iisy cobot stands out due to its intuitive operating features, which ensure that it can be put to use quickly and productively without any prior knowledge.

The robot uses the iiQKA.OS operating system, making it easy to install, configure and program. Tasks can be taught really easily by means of manual guidance. Thanks to the smart teach pendant smartPAD pro, any additional programming tasks are as easy as using a smartphone.

An optional pre-installed and pre-configured gripper makes the cobot even easier to use.

Custom-made or mass production._It’s iisy

Thanks to the new iiQKA.OS operating system and its industry-proven technology, the LBR iisy collaborative robot can be quickly integrated into existing production landscapes. At the same time, the cobot fits seamlessly into rapidly changing manufacturing environments that produce customized goods – even with a batch size of 1.

What is the significance of collaborative robots for business? For which target groups are they worth it? All questions relating to cobot are clarified in our e-book. Our aim is to provide you with information and inspiration and encourage you to test the possibilities opened up by cobots for your specific requirements.

3D simulation – get to know the LBR iisy cobot

Choose between two different applications and get a 3D preview of the LBR iisy, with or without a safety fence depending on your needs. You can view the selected application easily from all sides, zooming in and out to get a close look at all the details of the collaborative robot.