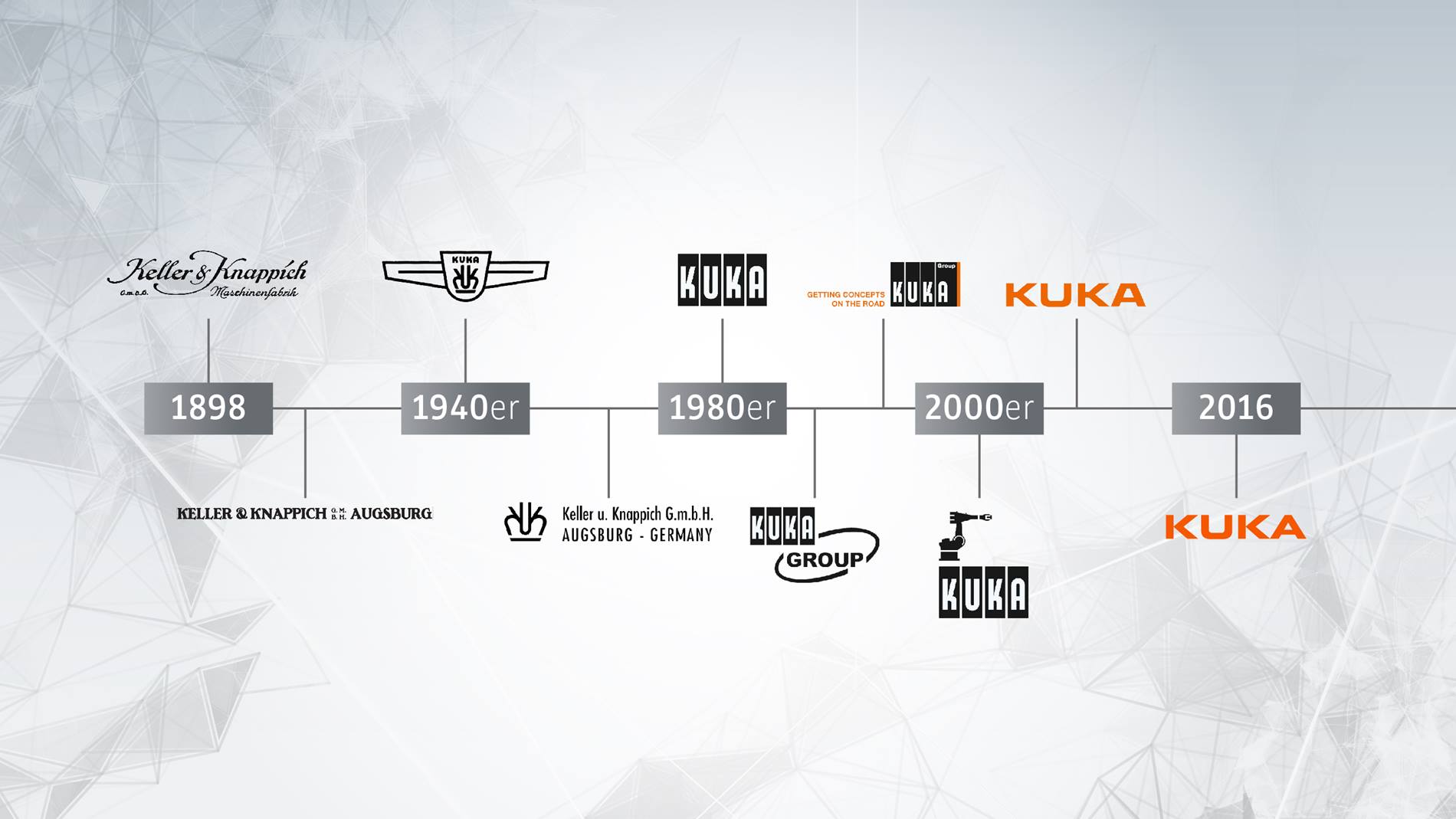

The history of KUKA

The history of KUKA begins in 1898 with Johann Joseph Keller and Jakob Knappich in Augsburg. Since then, the company has stood for ideas and innovations “Made in Germany”. Today, KUKA is one of the leading suppliers of intelligent automation solutions.

1898: KUKA turns on the lights

Johann Josef Keller and Jakob Knappich founded an acetylene gas plant in Augsburg, thus enabling cost-effective operation of domestic and street lighting.

1905: Prices fall, the product range expands

Just a few short years after the company’s founding, however, electric light sources hasten a drastic fall in prices for acetylene gas.

For this reason, Keller und Knappich GmbH extends its production to embrace a new invention: oxyacetylene welding. From this time onwards, KUKA continuously sets new standards in welding technology.

As early as the start of the 20th century, Keller and Knappich increasingly use a telegram abbreviation: formed from the initial letters of “Keller und Knappich Augsburg”, the KUKA brand is born.

1920 - 1970

1920: Portfolio and market expansion

KUKA soon begins to apply its expertise gained from welding and cutting, both for craftsmen in small trade enterprises and on an industrial scale, in other areas.

Among other things, the company manufactures large containers and superstructures for vehicles.

Just a few decades later, KUKA has established itself as the market leader in the field of municipal vehicles in Europe.

1939: Innovative spot-on solution

KUKA expands its portfolio and constructs the first electrical spot welding system in Germany in 1939.

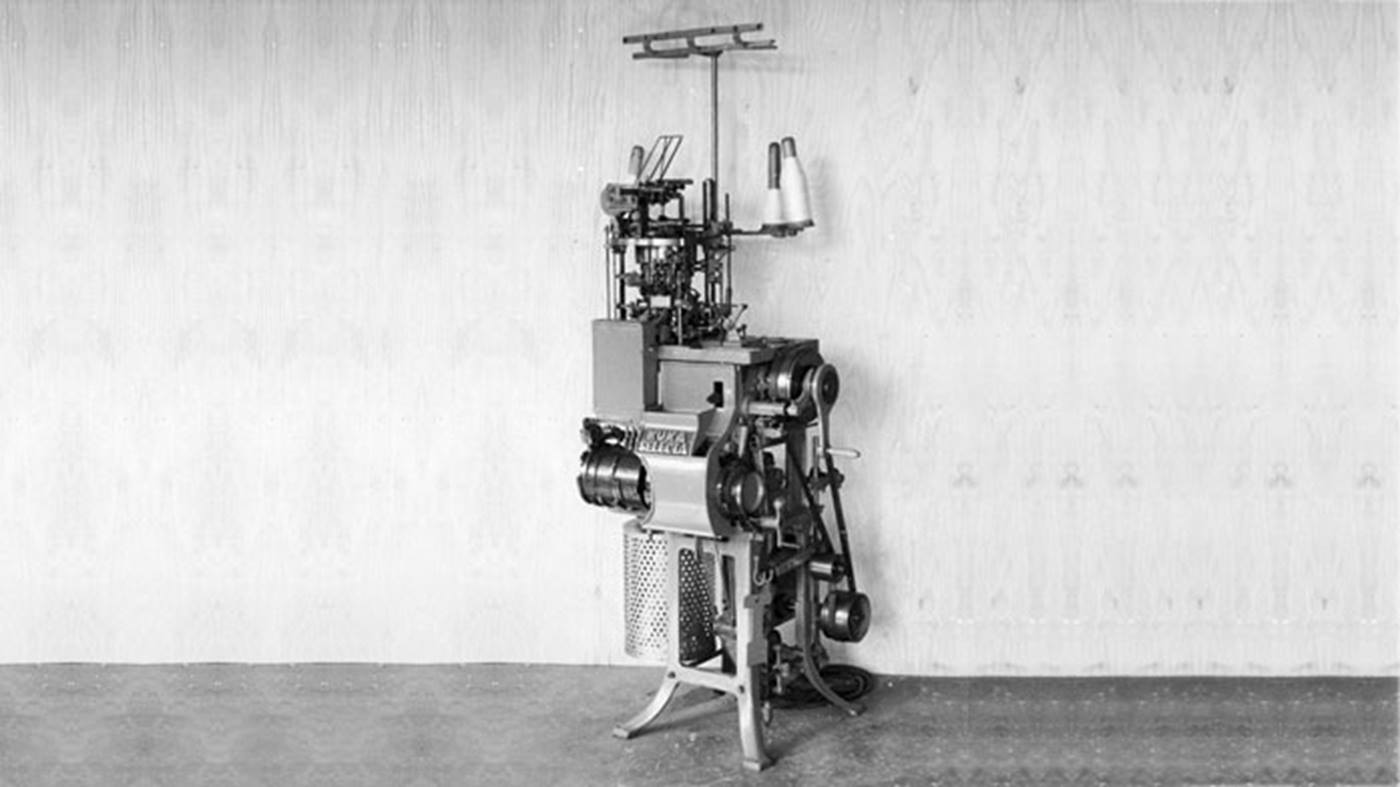

1949: KUKA knits and types its way into new product areas

The product range is extended beyond welding systems and large containers.

Measuring just 64 mm in height and weighing five kilograms: the compact “Princess” portable typewriter – a marvel of precision mechanics – is born.

The Selecta circular knitting machine is also launched onto the market and enables faster, more flexible production in the textile industry.

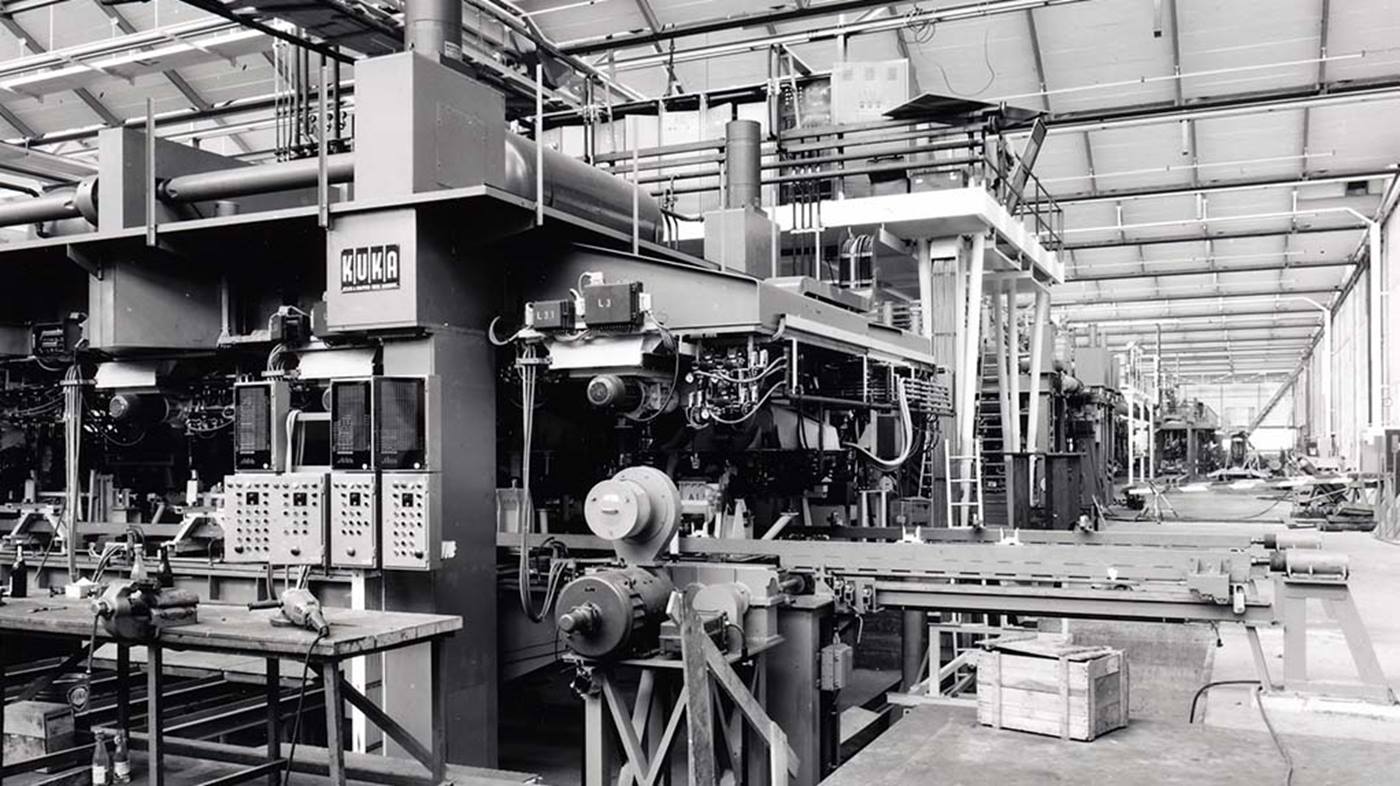

1956: Success through automation

The first automatic welding system for refrigerators and washing machines is market-launched by KUKA.

KUKA also delivers the first multi-spot welding transfer line to Volkswagen AG.

1966: Innovative welding technologies

KUKA establishes a new welding technology: friction welding. Numerous other innovations follow in the ensuing years, such as short-cycle welding and defined-angle friction welding.

1970 - 2000

1971: Taking a strong line with KUKA robots.

Europe’s first robot-operated welding transfer line is built for Daimler-Benz.

1972: More reliable, faster and more durable

The first Magnetarc welding machine is presented by KUKA. The process is continuously optimized. To this day, it remains one of the fastest and most reliable processes for joining components which have to permanently withstand extremely high loads.

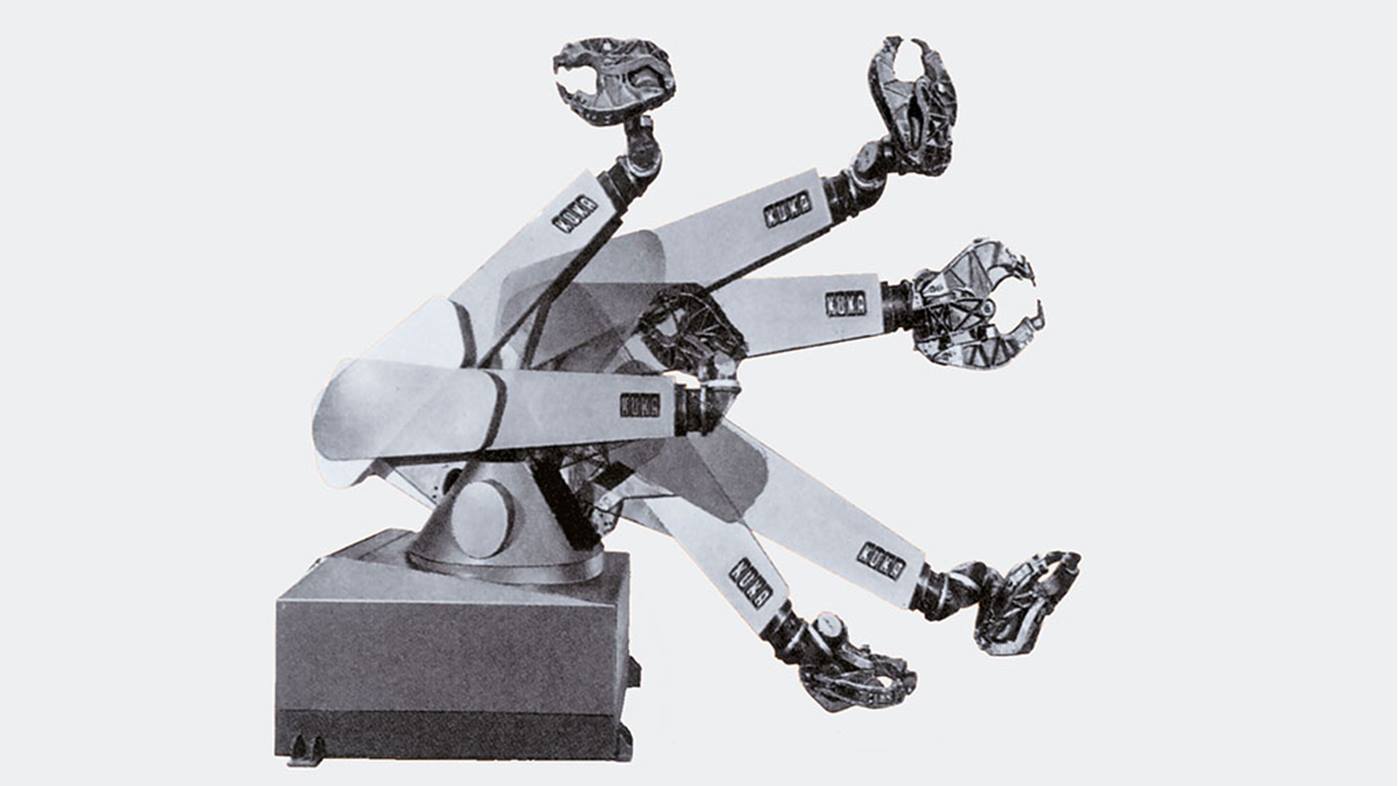

1973: Famulus, the robotics pioneer

KUKA wrote history as a robotics pioneer with the world’s first industrial robot with six electric motor-driven axes.

1989: Quality pays dividends

KUKA is the number 1 welding systems manufacturer in Europe.

The plant founded in North America at the start of the 1980s is also flourishing.

1996: Robot control by PC

KUKA is the first robot manufacturer to risk the paradigm shift to the PC-based robot controller.

1998: Into the Middle Kingdom

Robots are delivered to the Audi plant in Changchung. KUKA is one of the first companies with worldwide operations to export robots to China.

In the following years, KUKA opens a number of subsidiaries and production facilities of its own in China.

2000 - today

2001: Robots in medicine

KUKA robots are used in the world’s first robot-controlled radiation surgery system – the “Cyberknife”. The system enables the treatment of inoperable, surgically complex tumors.

2006: KUKA as complete solution

On behalf of the Chrysler Group, KUKA establishes KUKA Toledo Production Operations in North America for the integrated production of the body of the Jeep Wrangler.

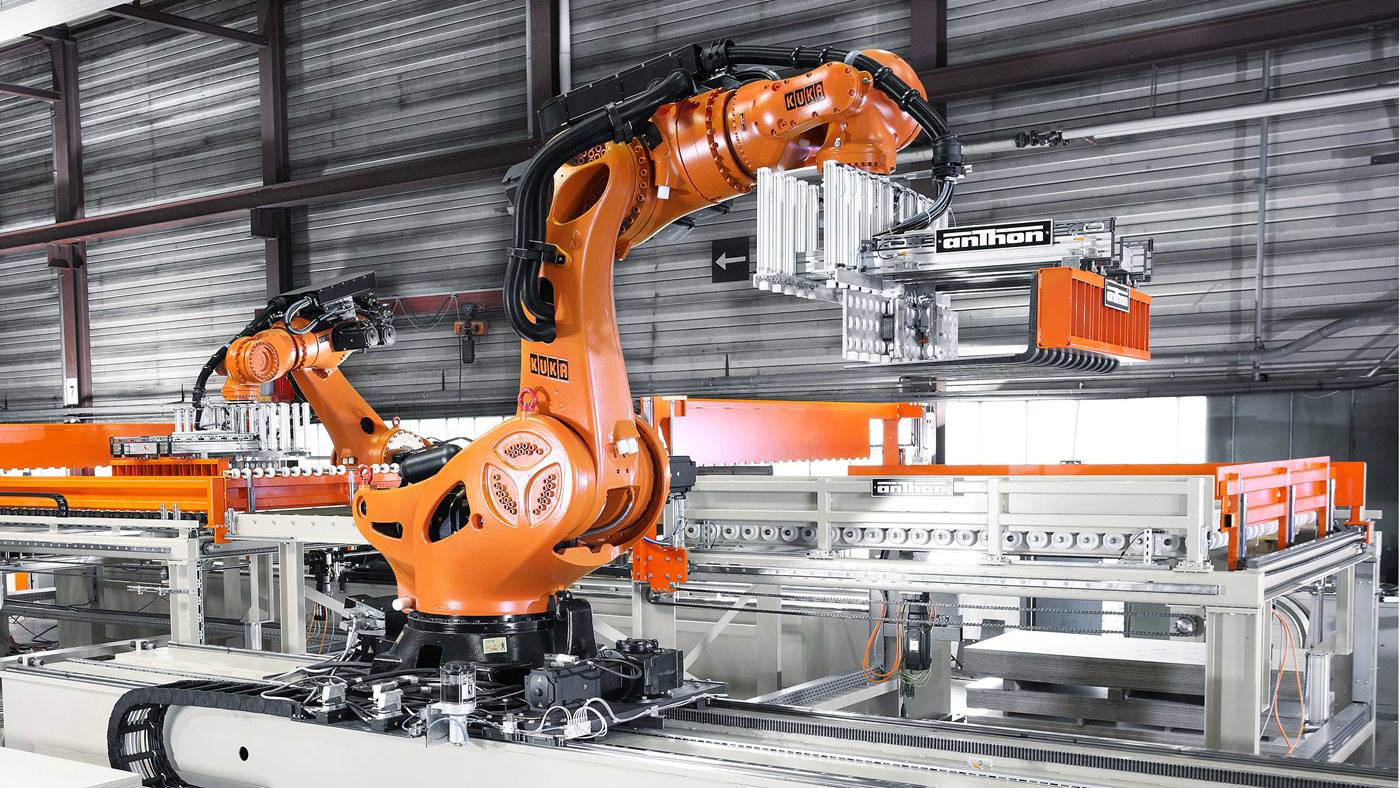

2007: World record holder with six axes

Payload capacity exceeds the magic mark of 1,000 kg. The KUKA KR 1000 TITAN receives an entry in the Guinness Book of Records as the world’s strongest six-axis industrial robot.

2010: Flexible high-flyer

With its unique payload range, the KUKA KR QUANTEC quickly becomes the world’s best-selling robot series.

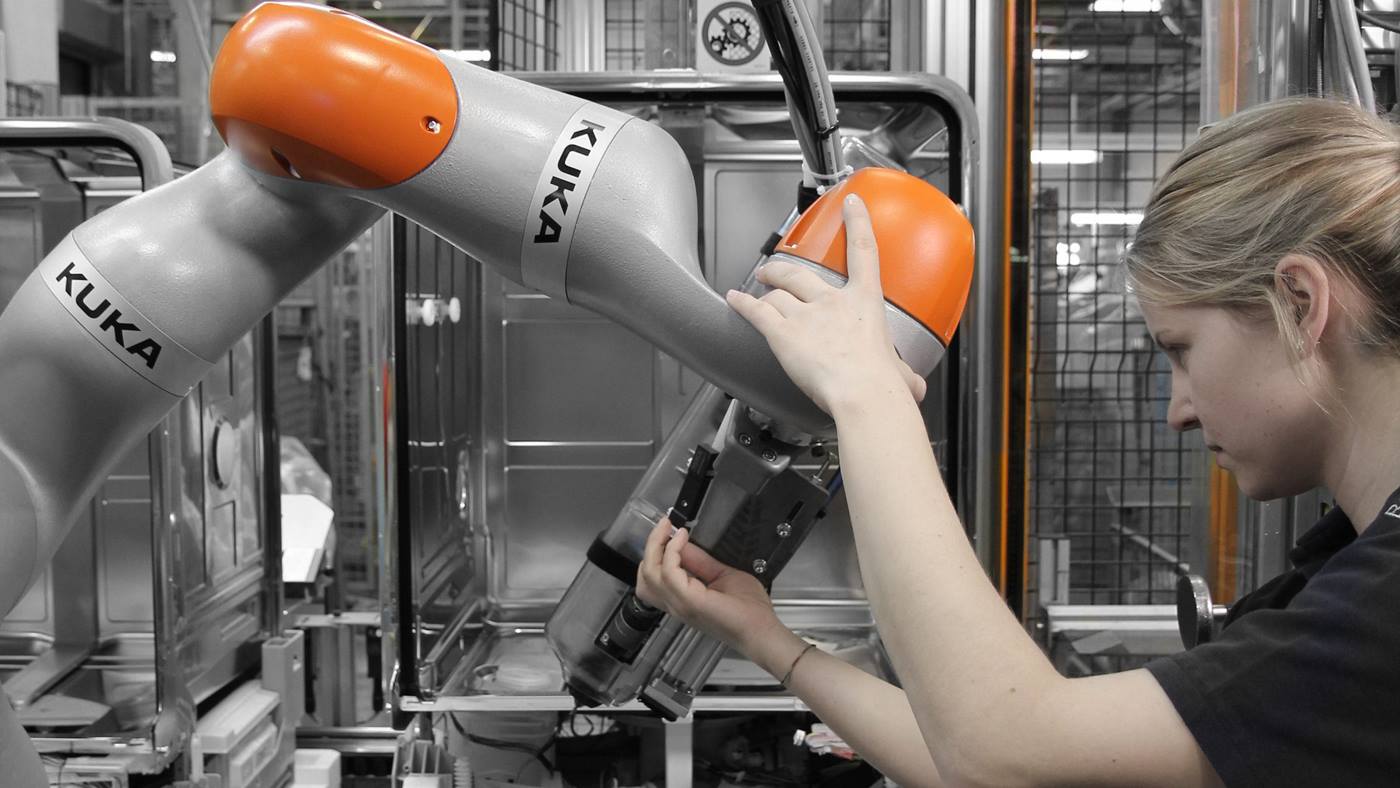

2013: Hand in hand with the robotic colleague

The LBR iiwa is the world’s first series-produced sensitive robot approved for direct human-robot collaboration (HRC).

The success story of cobots continues with the LBR iisy. It can be used both in industrial series production and in dynamic, unstructured workstations.

2014: KUKA continues to grow

KUKA AG merges with Swisslog Holding AG. Through Swisslog, KUKA gains access to attractive growth markets in the logistics and healthcare sectors.

2018: KUKA120 – Thinking Orange

KUKA celebrates its anniversary in 2018. Johann Josef Keller and Jakob Knappich turned the lights on 120 years ago – today, KUKA is one of the world’s leading suppliers of intelligent automation solutions for Industrie 4.0.

2019: Automation - simpler and more intuitive

2020: The pandemic keeps the world in suspense

2022: Record year for KUKA

2023: 125 years Keep on Moving

2024: A new business area

2025: Making Automation Easier