Hanplast headquarters are located in the Industrial and Technological Park in Bydgoszcz, which is also the seat of other modern and thriving companies. In contrast to the previous facility owner - Zachem Chemical Works – the companies located there, such as Hanplast, set themselves ambitious goals, which are the sustainable development and the care for the environment.

Sustainable development policy forms the basis of all activities undertaken by Hanplast. Part of the energy supply for the production process is produced by the company itself, using approximately 10,000 m2 of self-made solar panels deployed on the roof of the main building (8,000 m2) and tool rooms (2000 m2). This energy powers a modern, highly automated production process.

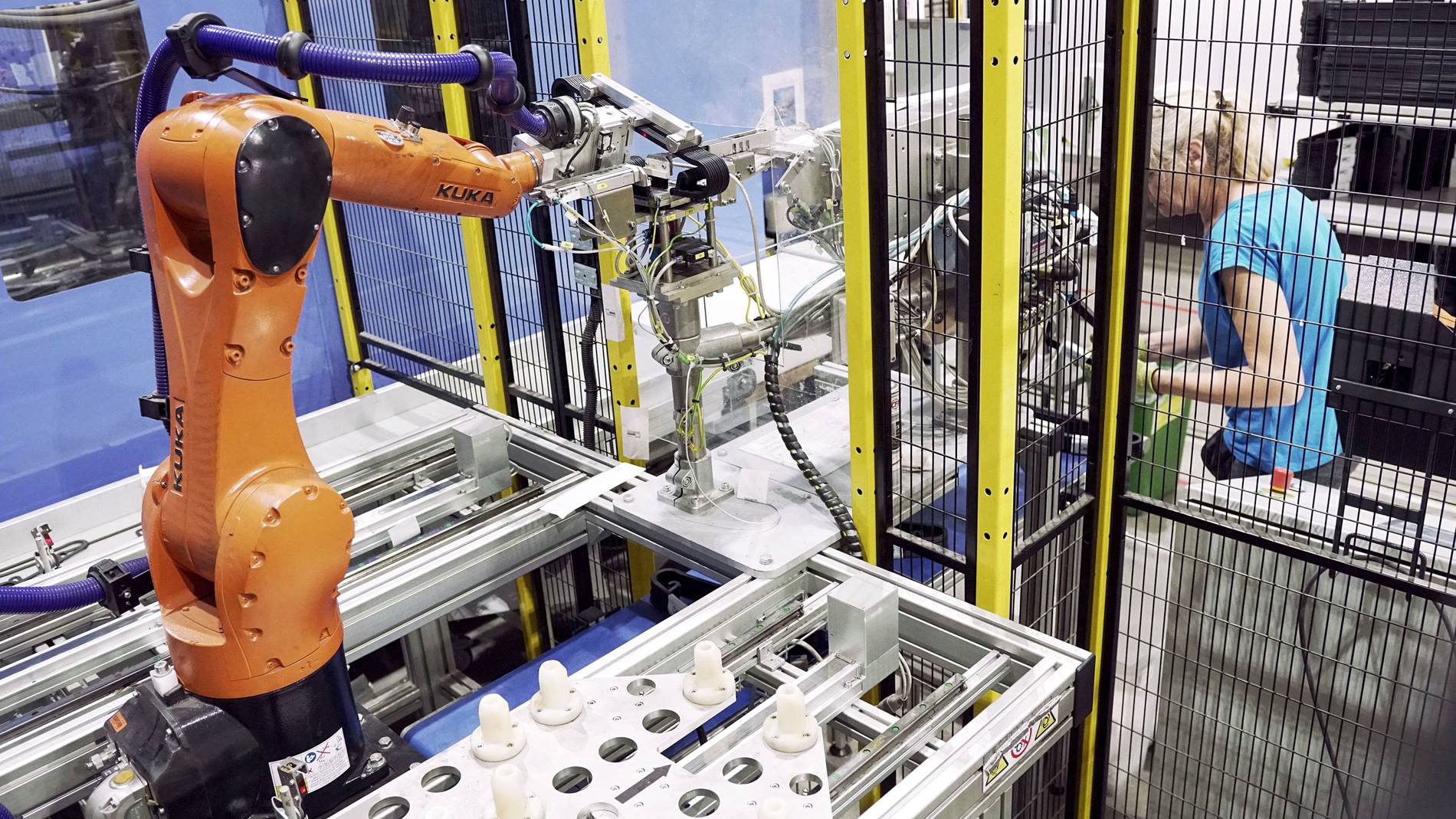

- At this workstation, we pack approx. 2400 items per hour, which are packed in packages of 10 pieces. Each package must be labelled. Without the automation, two operators would be needed to handle this process - explains Robert Powalisz.

Limiting the number of operators in this case brought several benefits. Improved labour productivity, which was earlier pointed out by the Head of the Technology Department, can be considered the most important, but not the only one. Another advantage is the elimination (or significant limitation) of the problem of the lack of human resources, which many companies have to face today. The next one is a guarantee of 100% repeatability of the labelling process.

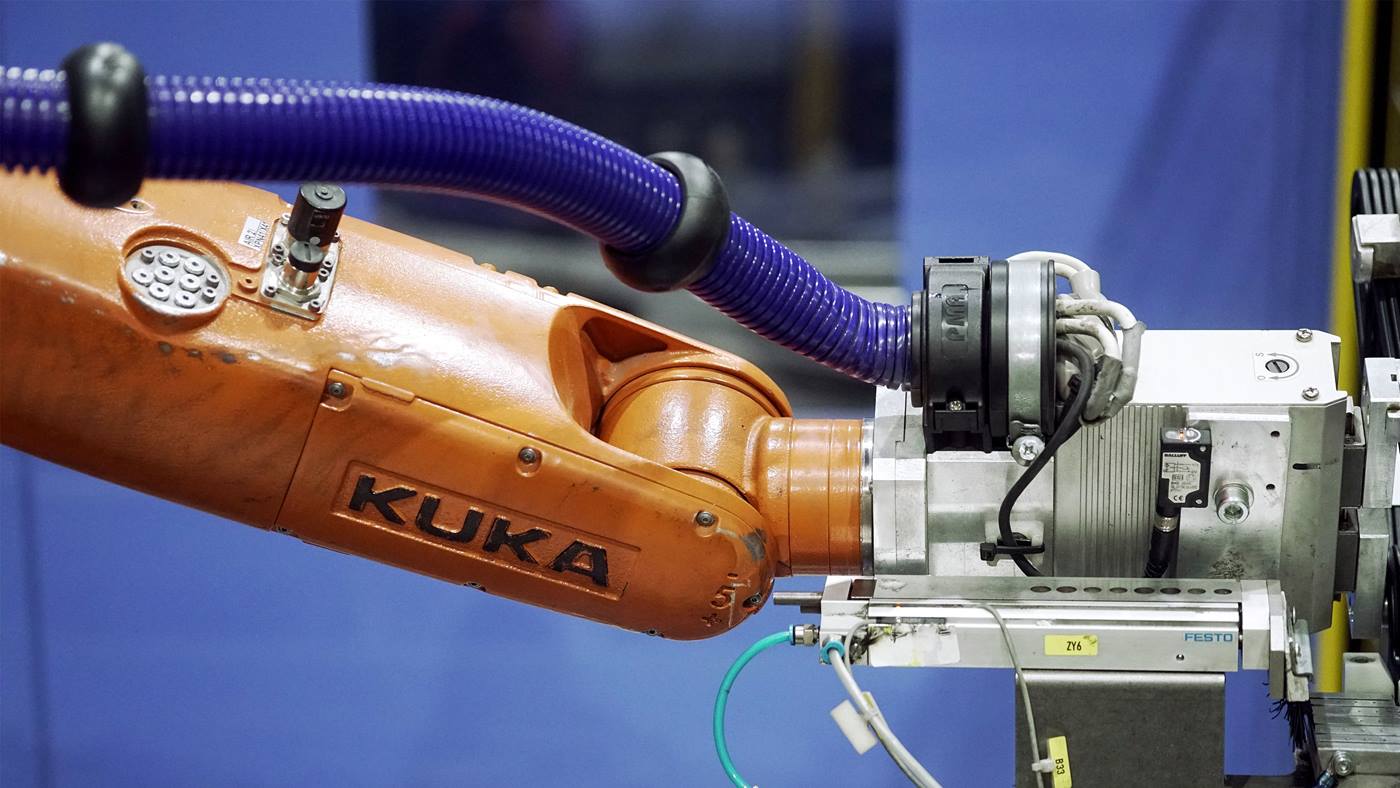

What exactly is the role of the KUKA robot within the labelling workstation?

Finished elements of home furnishings manufactured, are firstly deposited by the integrated arm on special loading buffers. Once they are loaded (in a precisely defined number of pieces), the buffers are automatically transported to the work area of the KUKA robot. The role of the robot is to take exactly 10 pieces of the product, and pass them on to be labelled. Labelled products go to the loading container. Everything happens under the supervision of the operator, whose task is also to pack the production lots. Finished products go to one of the key clients of Hanplast.

Hanplast has been running the comprehensive automation of production, from injection moulding machines to processes related to logistics, for years. The first robotic positions in the company's production were launched more than a decade ago as a result of the dynamic development of the Bydgoszcz factory. Today, there are several dozen independent positions that are supported by qualified employees. There are plans to launch more - all to meet the challenges of the modern World, guaranteeing the highest quality of our products