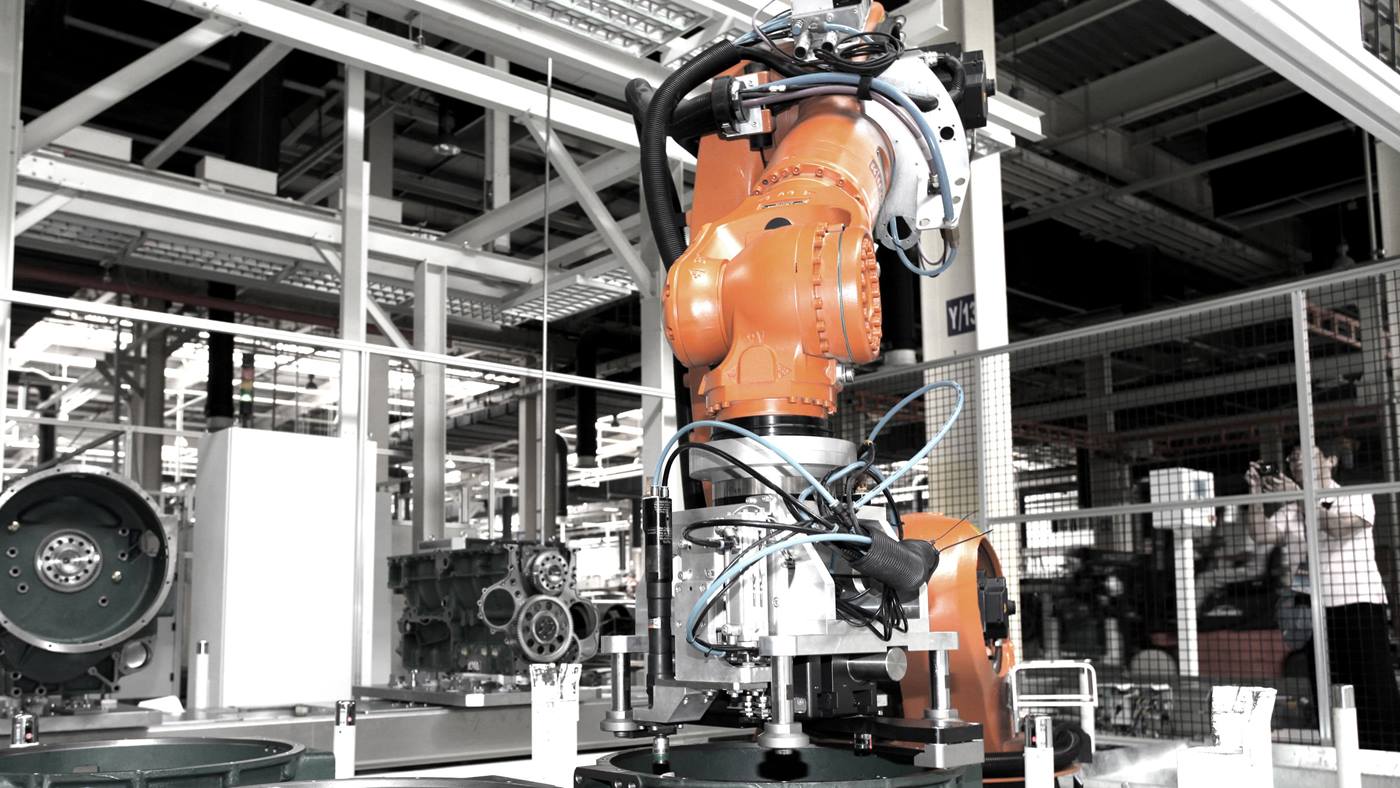

Massive cylinder blocks require a heavy-duty robot

Titan from KUKA handles the cylinder block with ease

As soon as the cylinder block, weighing 500 kg before assembly, reaches the work island, the KUKA KR 1000 titan picks it up under sensor control and sets it down on a workpiece carrier. From here, the cylinder block passes through several work steps, including the installation of connecting rods, cylinders, oil pans, etc. During this assembly work, the robot must rotate the cylinder block exactly 90 degrees at a defined point. Upon completion, the cylinder block - now weighing 700 kg - is brought back to the island station where the KR 1000 picks it up and performs a 180-degree rotation to set it down on the workpiece carrier. The assembled block then continues its journey through the assembly line.