‘Edition’ robots ease entry into automated arc welding

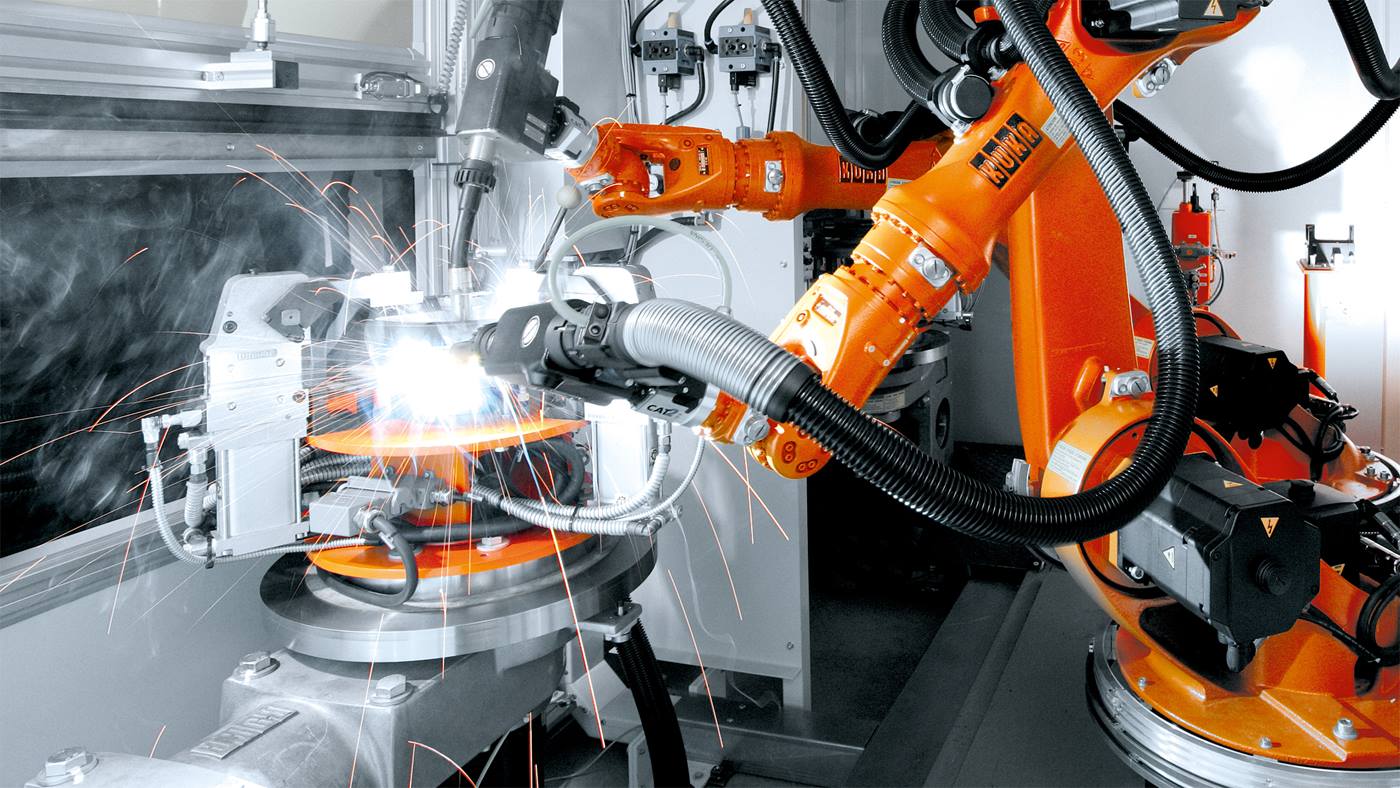

KUKA "Edition" robots help new customers automate welding tasks efficiently in price-sensitive markets. These focused robots offer an ideal cost-benefit ratio within the current KUKA technology portfolio. Initially, the KR CYBERTECH nano ARC will initially be available in two "Edition" variants, with other KUKA robots to follow.

17 April 2023

Smaller investment, easier automation

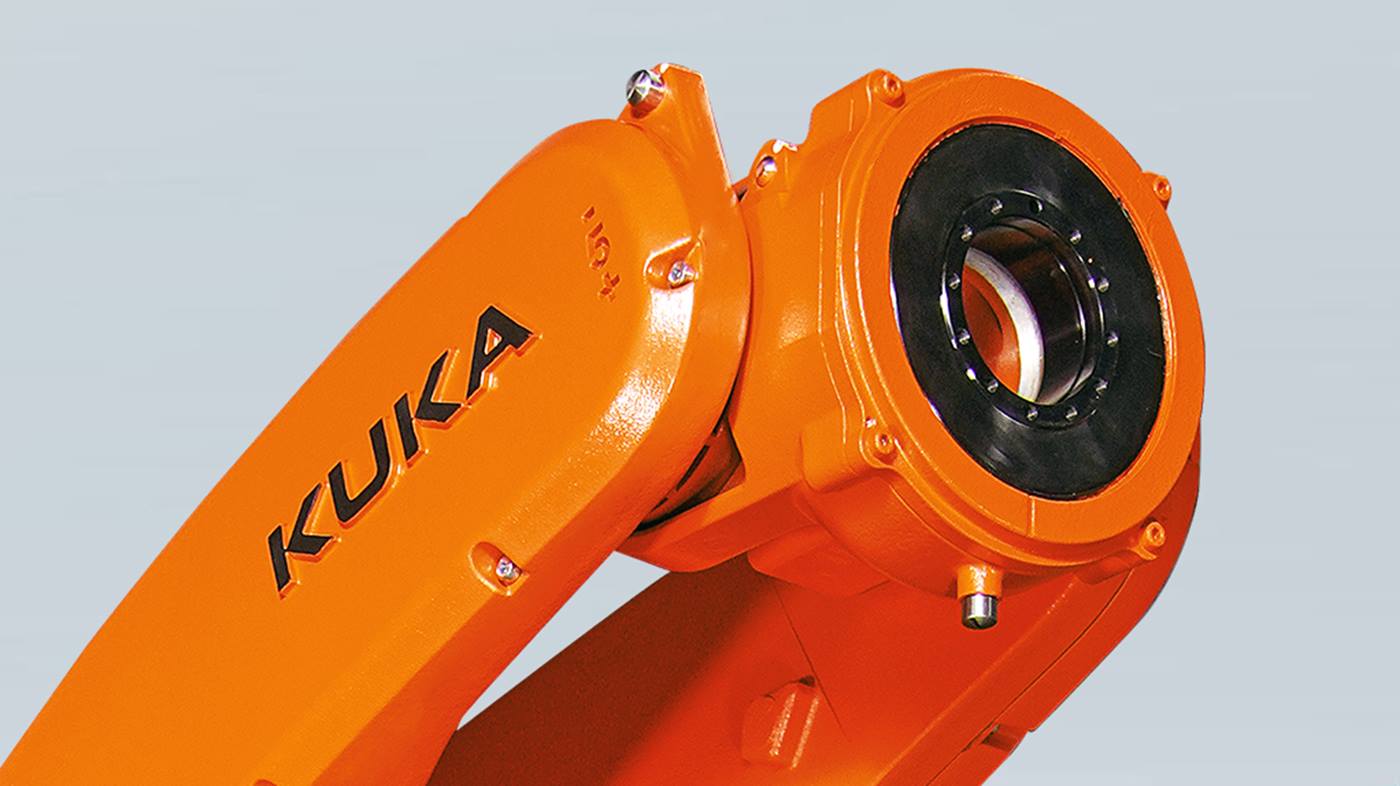

“This is exactly right for entry-level applications in the field of arc welding,” Hollfelder-Asam confirmed. “We were determined to deliver typical high KUKA quality. This means the hollow wrist supports optimal positioning for the welding process and avoids additional disruptive contours. Additionally, “Edition” robots include a maintenance-free cable set like the KR CYBERTECH nano series.”

"Edition" robots incorporate industry-proven quality perfectly suited to the global requirements of entry-level welding applications. KUKA will launch the KR CYBERTECH nano ARC HW Edition robot first, followed by additional "Edition" robot types.