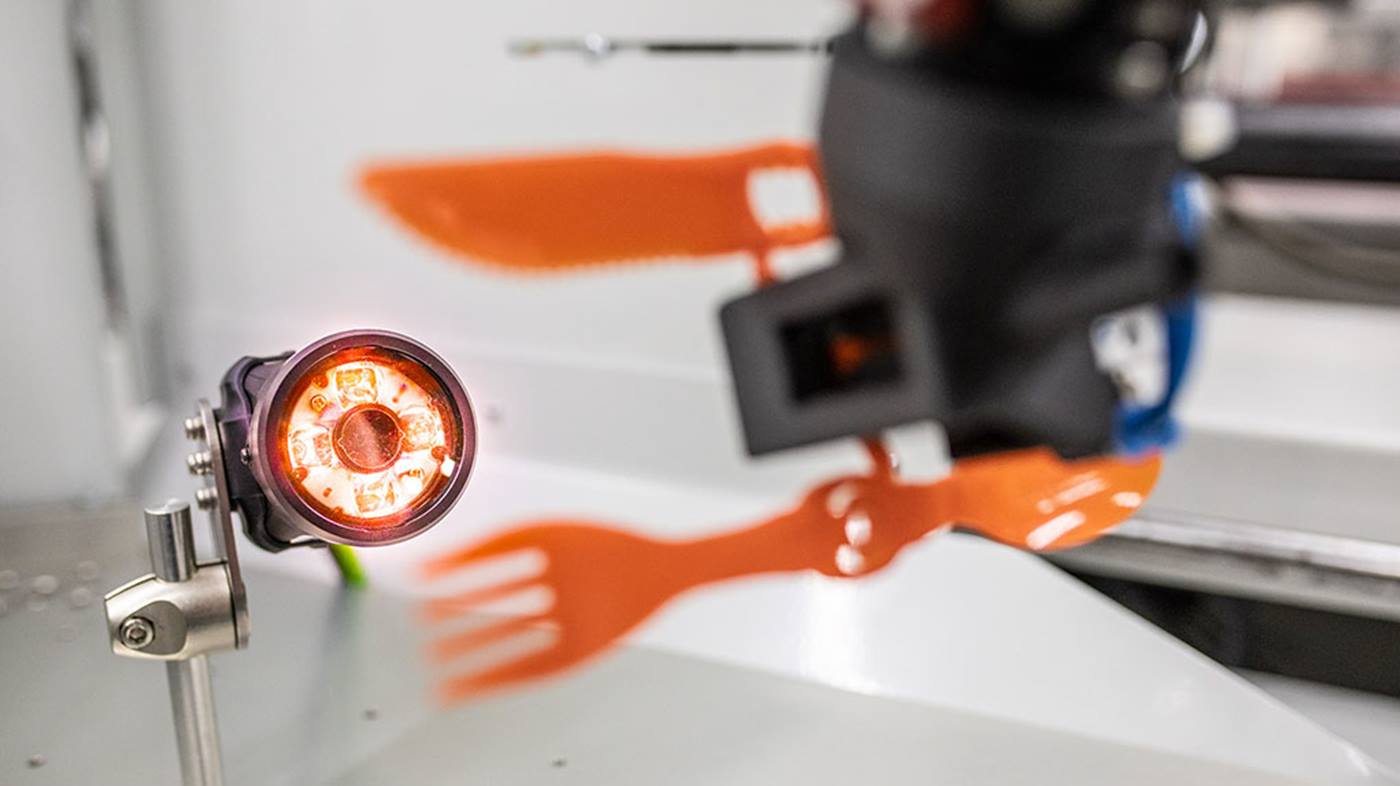

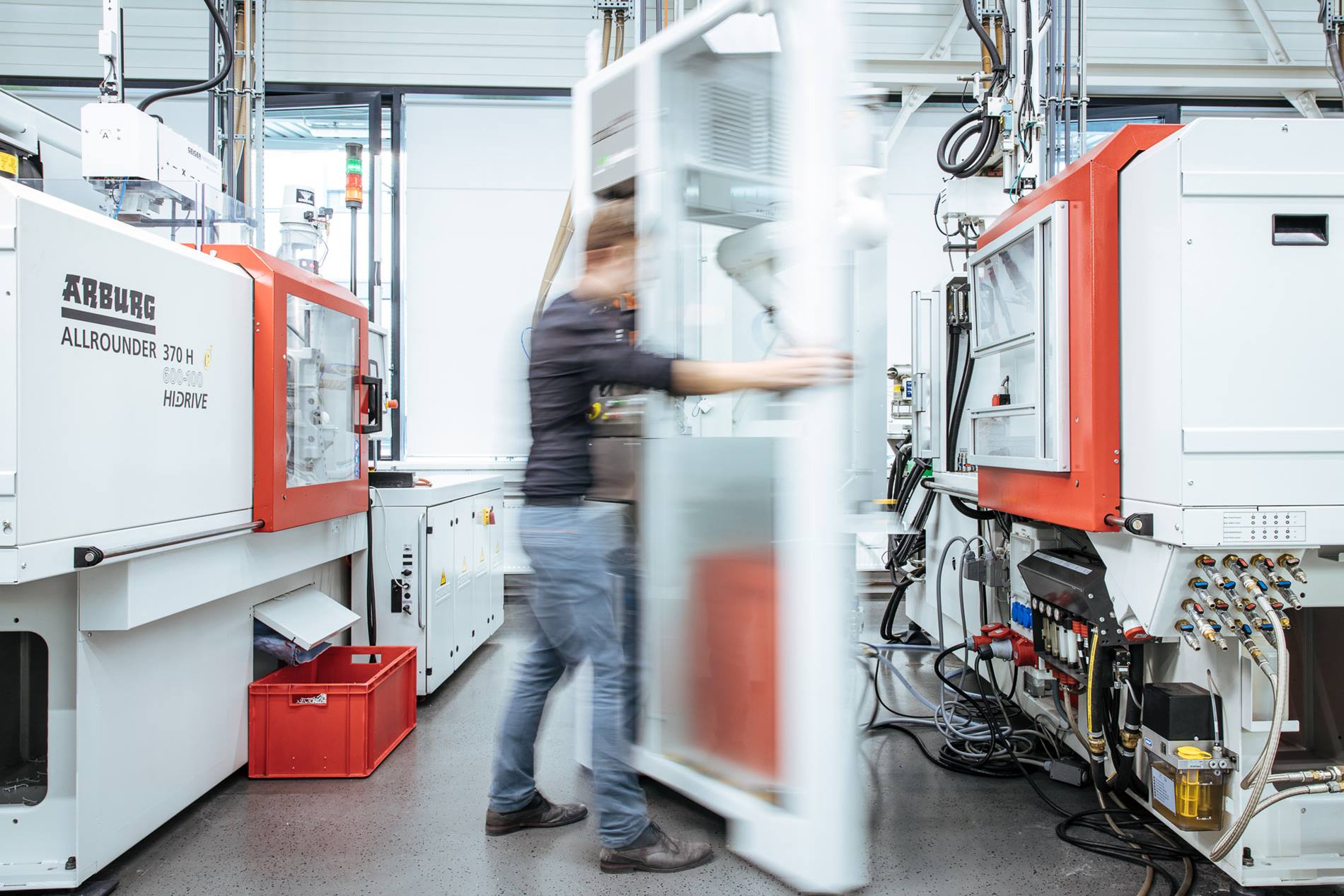

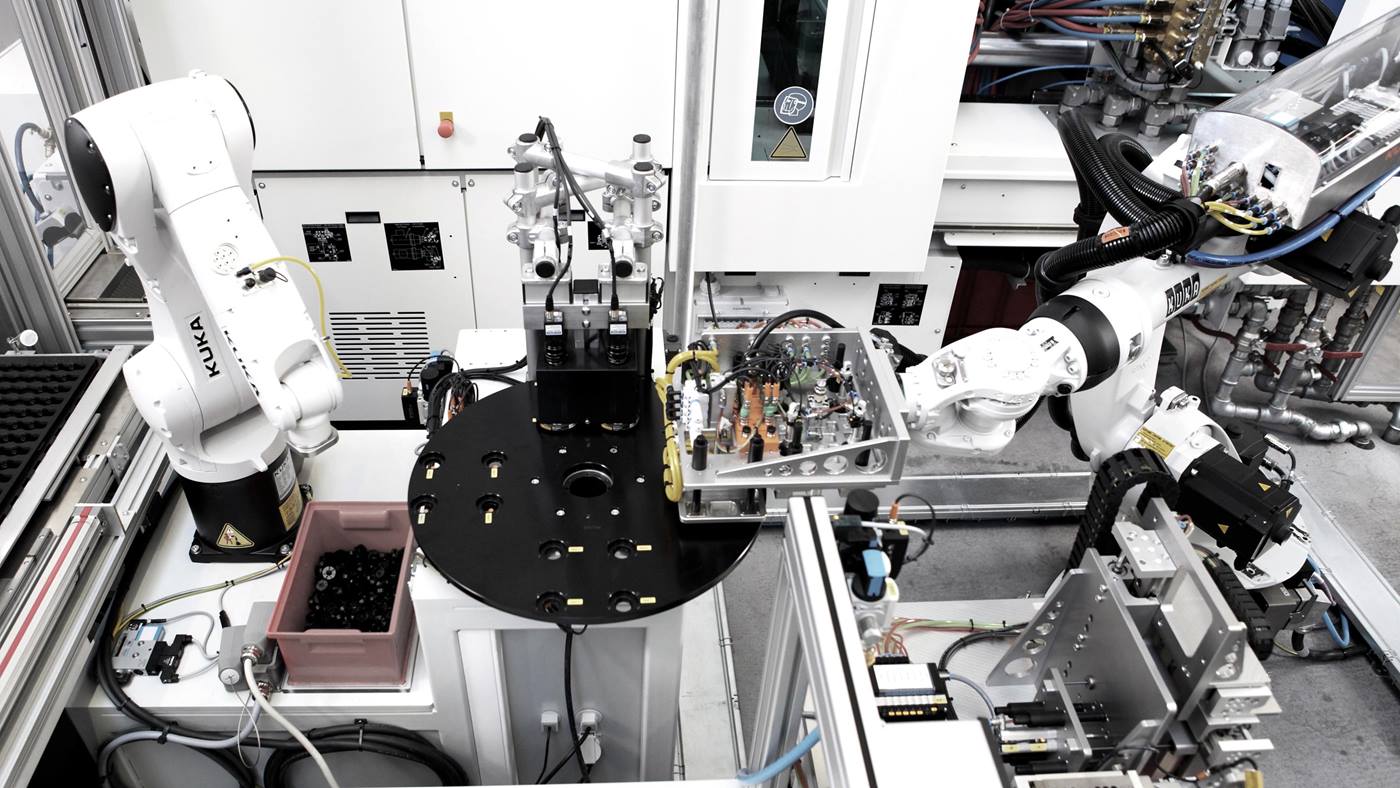

Automated manufacturing with a robot cell for injection molding

Moving away from disposable products and towards sustainable consumption. This is the goal that students at University of Applied Sciences Reutlingen set themselves as part of a project. They were looking for an alternative to disposable plastic cutlery at trade fairs. Reusable cutlery made of high-performance plastic is the result, developed under the stewardship of Prof. Dr. Steffen Ritter. The cutlery meets all of the requirements of the food industry and is both multi-functional and sustainable. The manufacturing process at Gindele GmbH, located near the southern German city of Pforzheim, is implemented using a robot cell for injection molding.