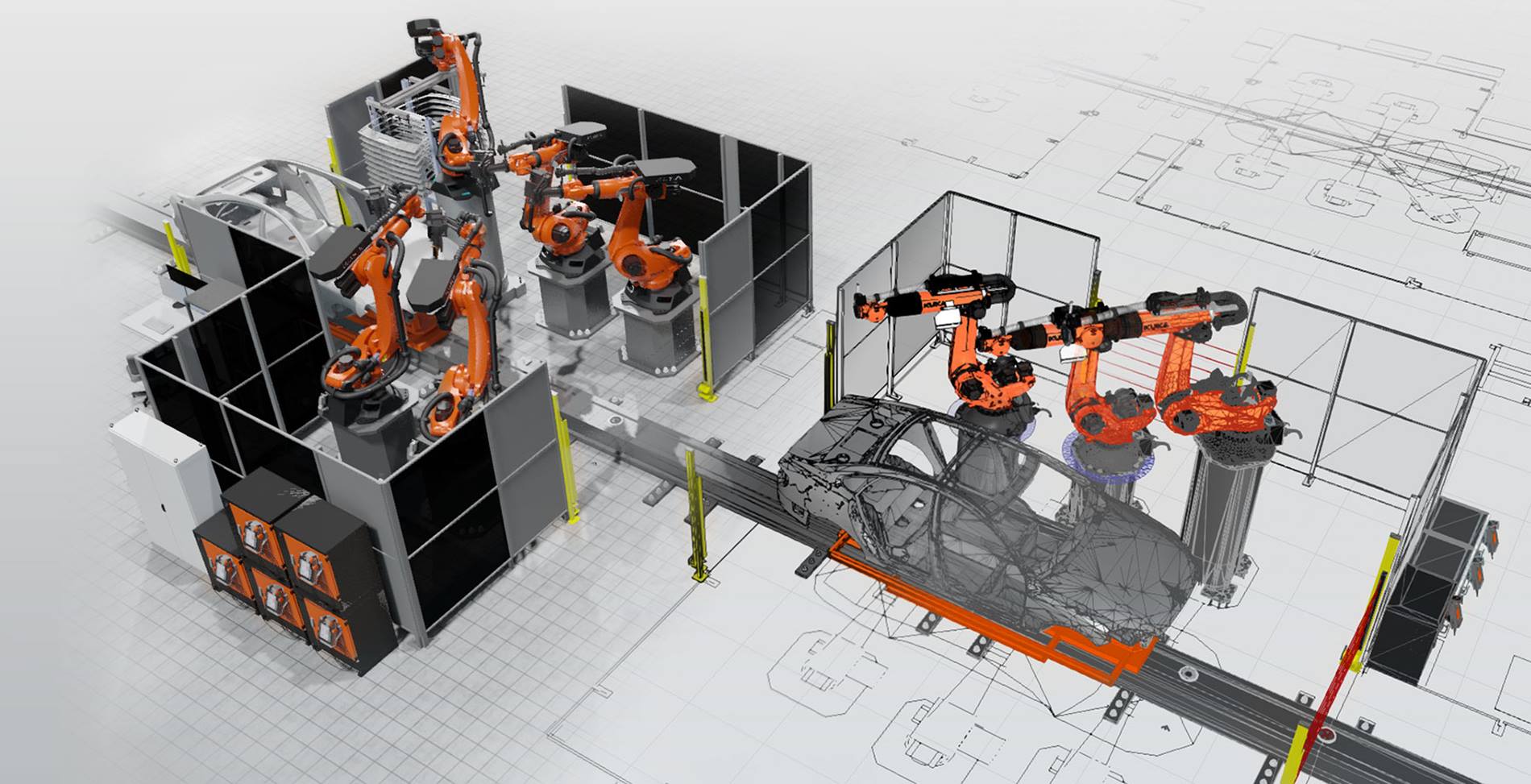

Automation perfectly planned with KUKA know-how

From selecting the robot to simulation

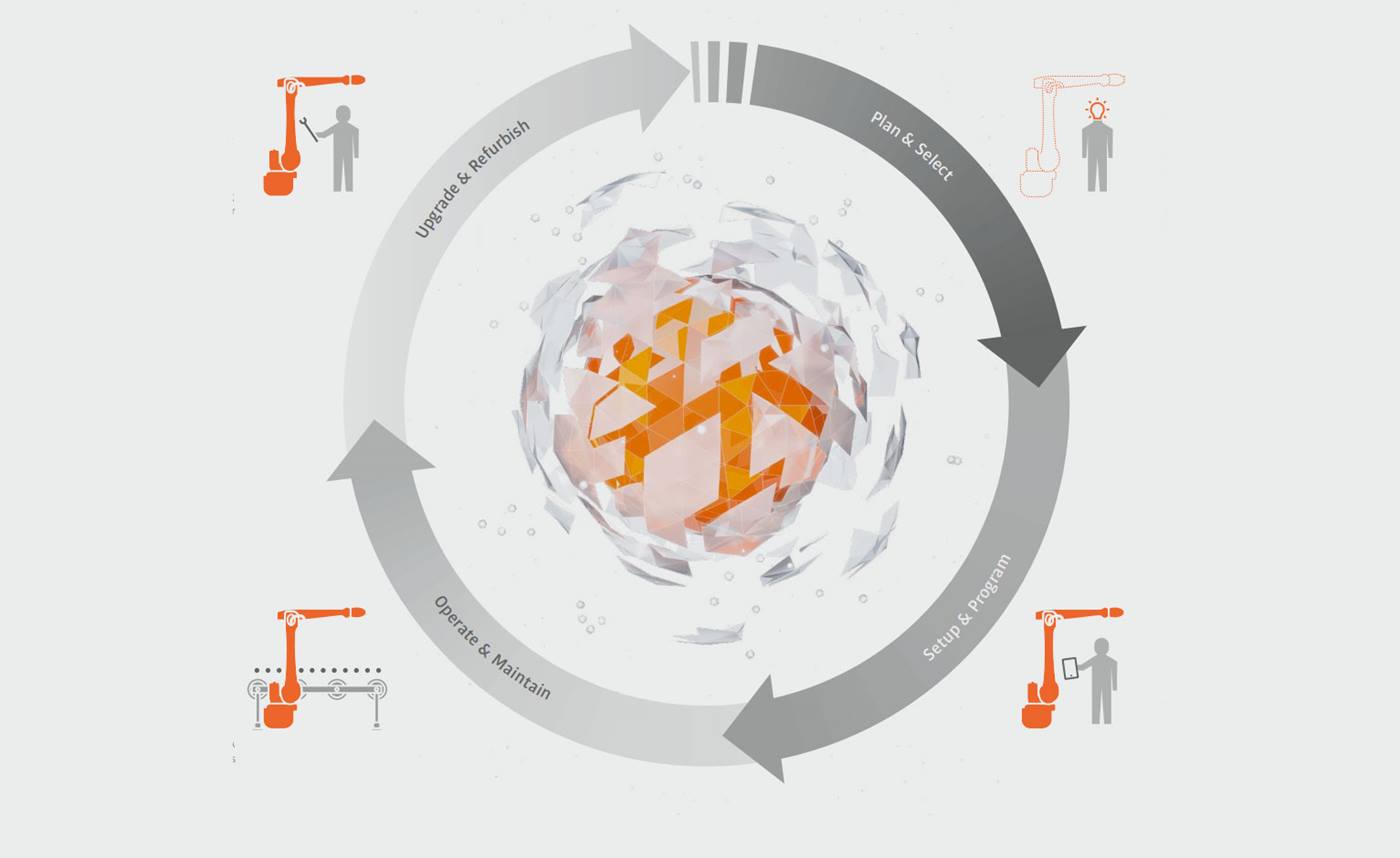

If robot automation is to be successful, it is essential that you select the most suitable robot types and models and use the right technologies in your system. Our experts plan and test solution concepts through feasibility studies, prototype production and simulations, thus reducing risks and planning times.

We will support you during the system planning process with suitable service products so you can turn your automation idea and your requirements into a complete implementation concept in a short space of time, with little effort and cost.