Magnetarc welding: the technology

Magnetarc welding can be subdivided into four different stages:

- Initial phase: The clamped components are brought into contact. The weld current is then switched on.

- Ignition: In a defined retract motion, the components are moved apart, thereby striking the arc. The arc is rotated by means of a magnetic field.

- Heat input: The rotating arc heats the weld surface. The speed of rotation and orbital path of the arc are precisely controlled, as are the progression and quantity of the energy input.

- Forge phase: The individual components are joined to one another in a forging process. The forge velocity and forge force are defined for each specific component.

A prerequisite for this pressure welding process is that conductive and fusible materials are used and the components have tubular cross-sections. Magnetarc welding is suitable for wall thicknesses of 0.7 to 10 millimeters.

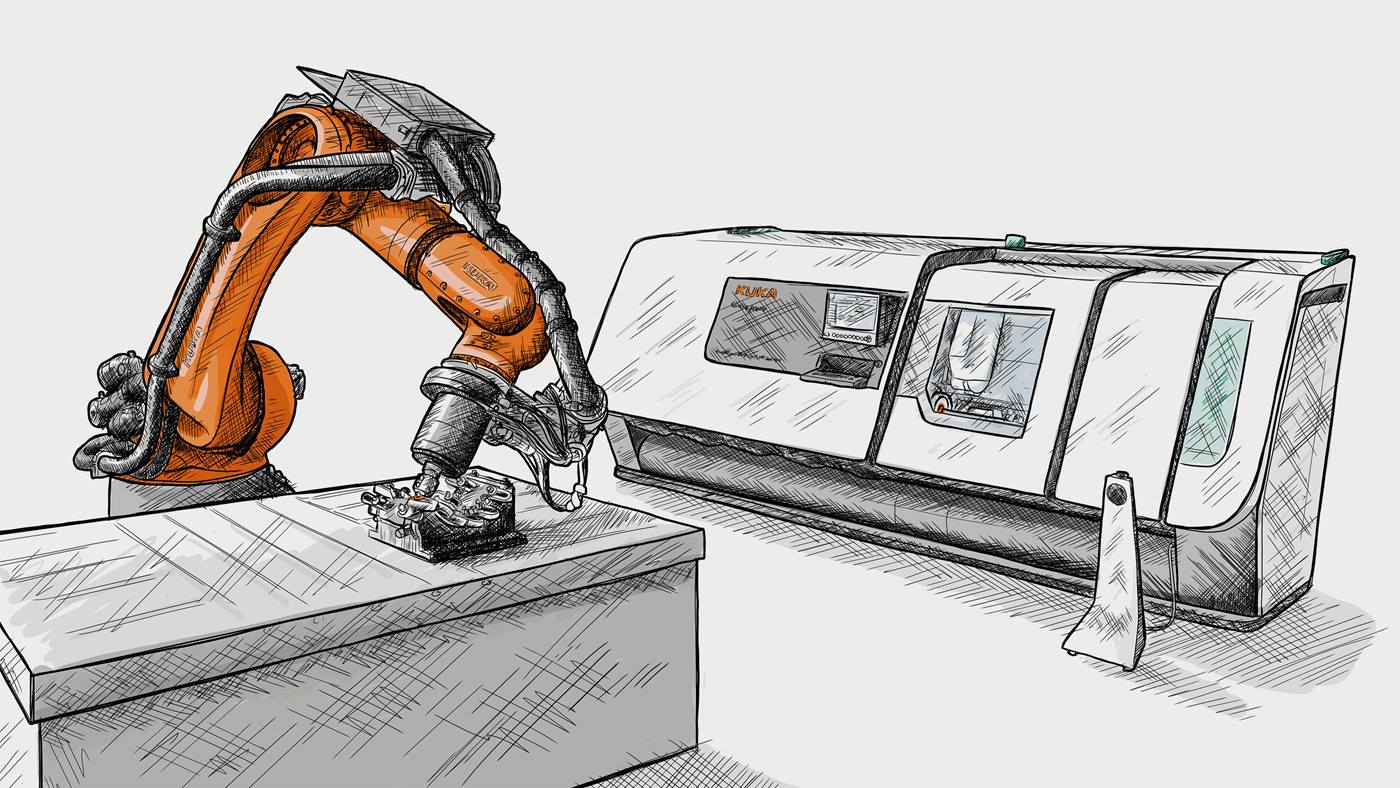

Automated Magnetarc welding

From semi-automation with linear axes and concepts involving robots right through to complete, integrated solutions – as a KUKA customer, you will receive a Magnetarc welding package that is perfectly tailored to your production system. We use 3D process simulations to help us achieve this. This enables us to optimize the process at an early stage with regard toproduction sequences, the integration of robots and human-robot collaboration.

At the same time, we pay due regard to energy and resource efficiency, thus increasing the cost-effectiveness of your production processes.

Magnetarc welding: the advantages

Magnetarc welding technology has three main advantages:

- Cost reduction: With very short welding times, no filler materials are required in Magnetarc welding.

- Top weld quality: The technology stands out thanks to low distortion and a high level of reproducibility.

- Process reliability: You have full control of the process at all times thanks to excellent process control and monitoring functions.

We would be delighted to talk to you about implementing Magnetarc welding at your company. Give us a call and we would be happy to advise you.