Spoon-fed

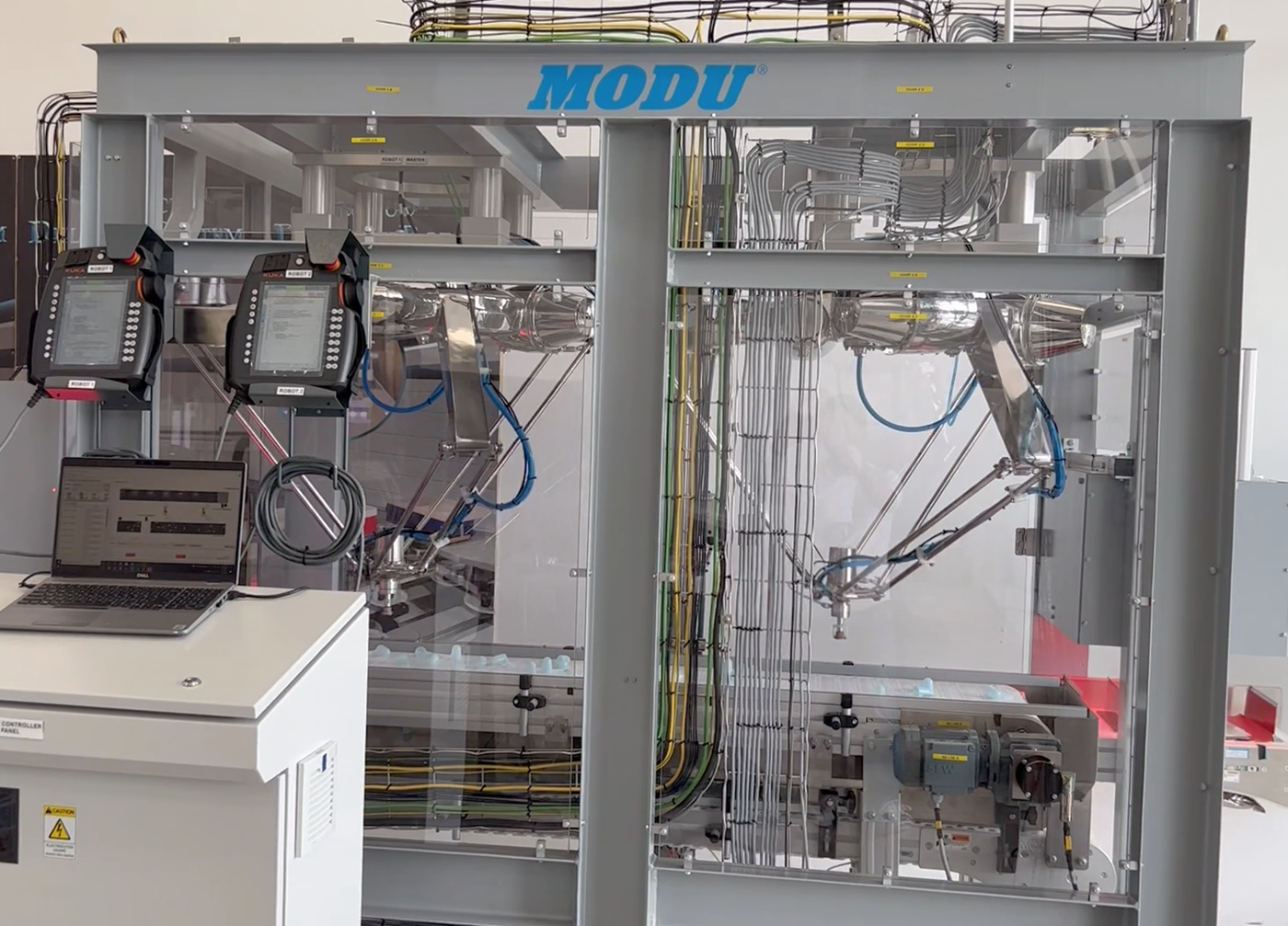

To distribute baby-food measuring spoons quickly, system integrator MODU System in Malaysia opted for a KR DELTA from KUKA. The Hygienic Machine version of this high-speed robot is ideal for its task – and the KR DELTA can do much more.

Pick and place: it’s a scoop!

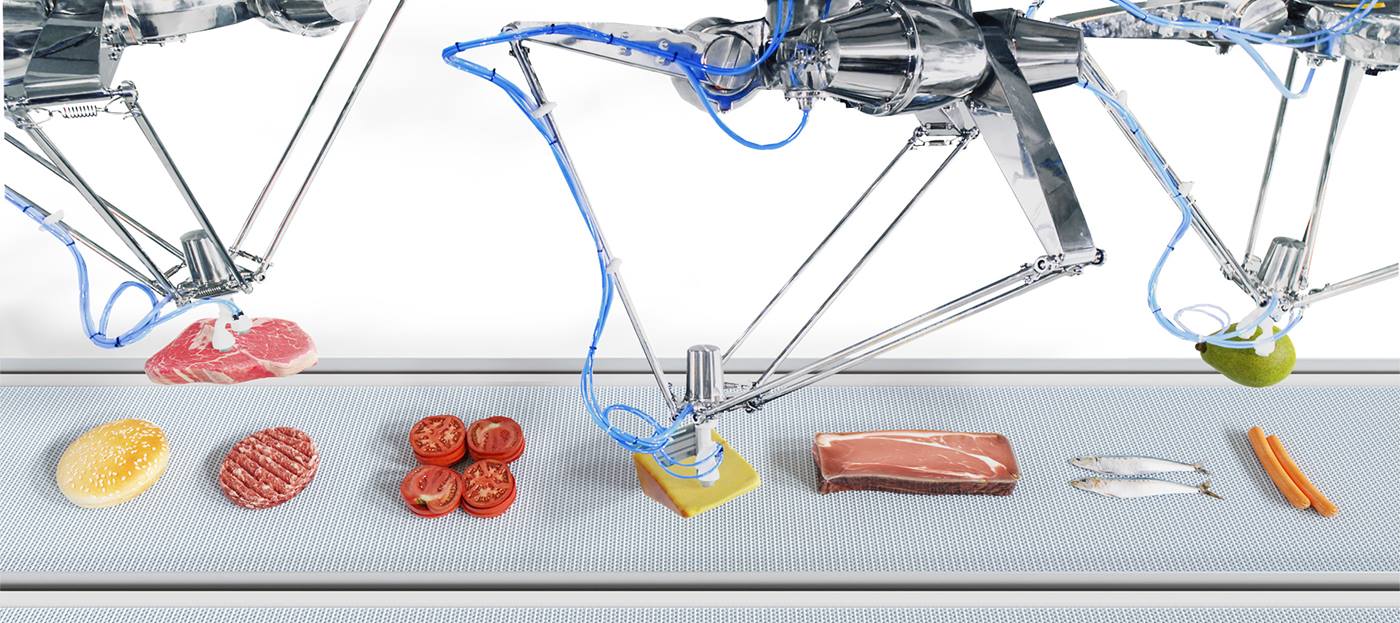

KR DELTA scores in the food industry

Up to 80 spoons per minute

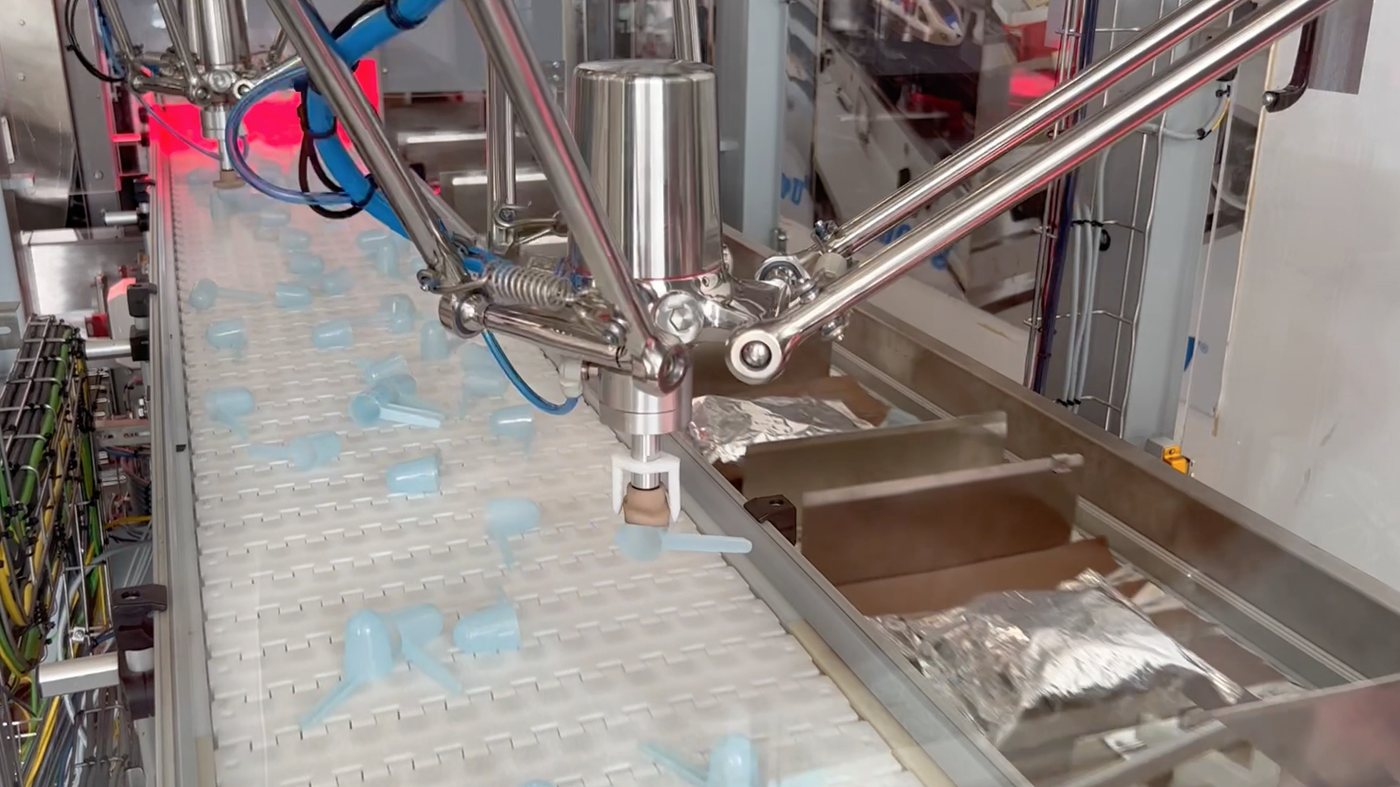

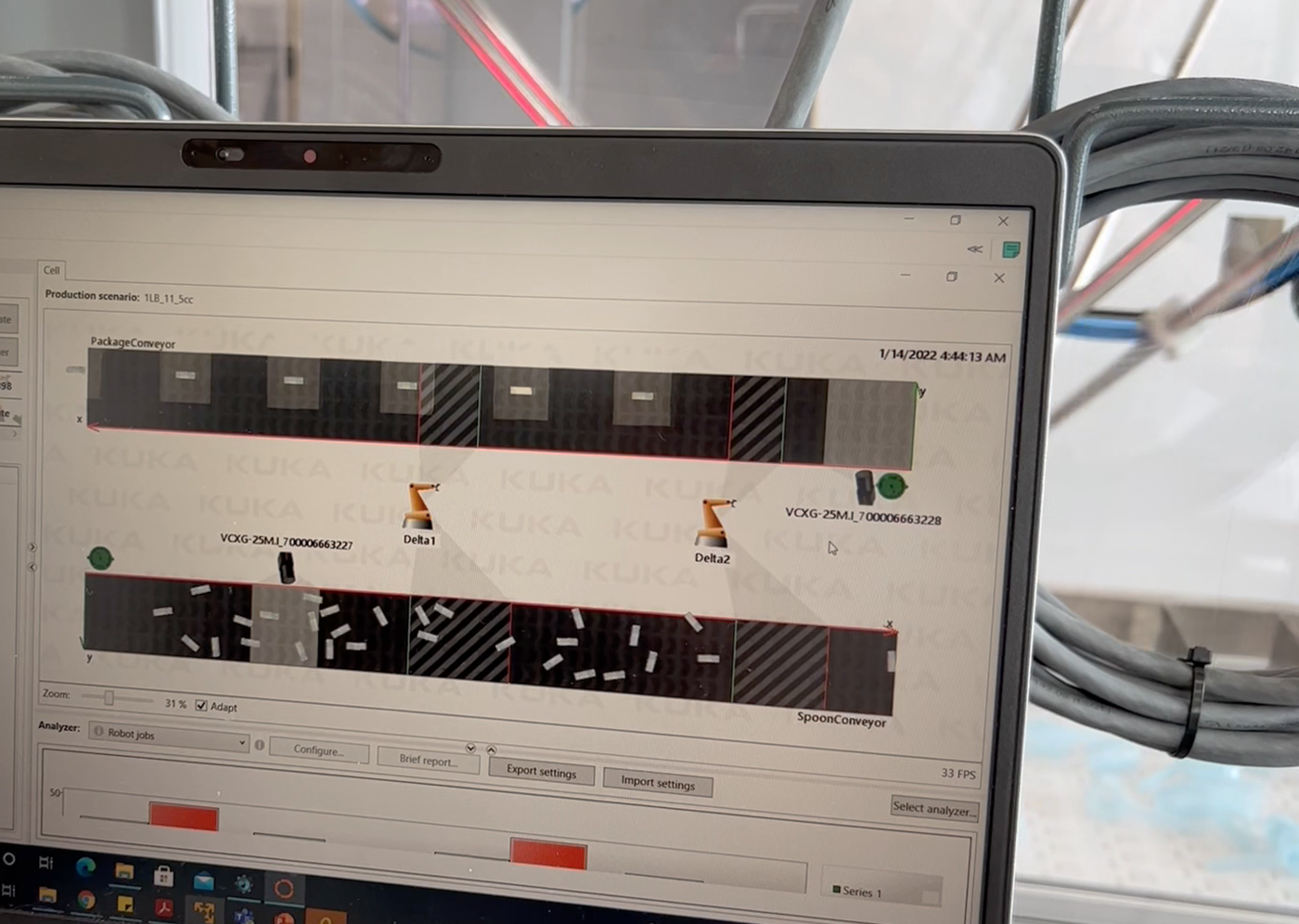

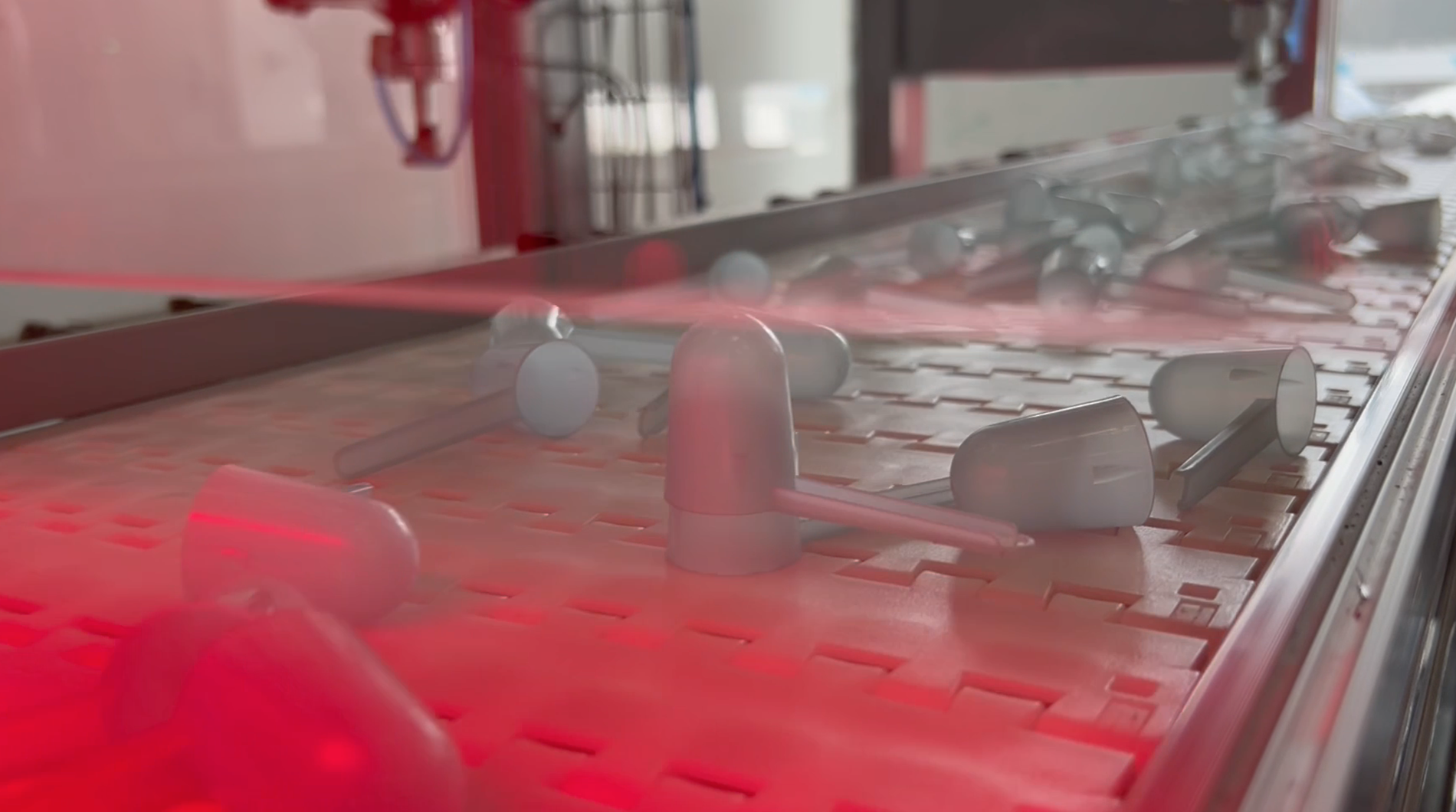

With a cycle time of as little as 0.5 seconds, the KR DELTA is ideal for pick-and-place tasks. “Two robots manage about 80 spoons per minute,” said Jia Ming. At the same time, they work extremely precisely, avoiding potential manual errors. One of the biggest initial challenges for this process was accurate calibration. This is a precondition for the two KR DELTAs to grip the spoons with precision at high speed.

Before automation, the baby food manufacturer carried out this process as a potentially dangerous manual step. The Hygienic Machine version of the KR DELTA makes this a completely hygienic process – and a highly compact solution. Ceiling mounted above the assembly lines, each of the two robots occupies an installation diameter of just 350 mm.

A question of the right position

Programming offline, testing in real time

This robot is picky

Spoon filtering made easy

The system is very easy to operate, looks good, and the stainless steel robot design convinced our food-industry customer. I am very satisfied with the automation.

Blue, green or orange: spoon color does not matter

All the measuring spoons are the same shape, but the customer uses blue, green and even orange ones. These varying colors presented a further initial challenge. “For example, if the customer uses a blue spoon, red light is ideal for the vision system to detect spoon position. A combination of lighting colors shortened the image processing time,” said Singh. RGB lighting easily accommodated this setup.

A final inspection camera monitors the entire process. “The customer has great confidence in the automation solution that KUKA and MODU System have developed,” Singh explained. “We ourselves are very impressed with the stainless steel design of the KR DELTA and believe that the application is ideally suited to the food industry, which places great emphasis on hygiene.”