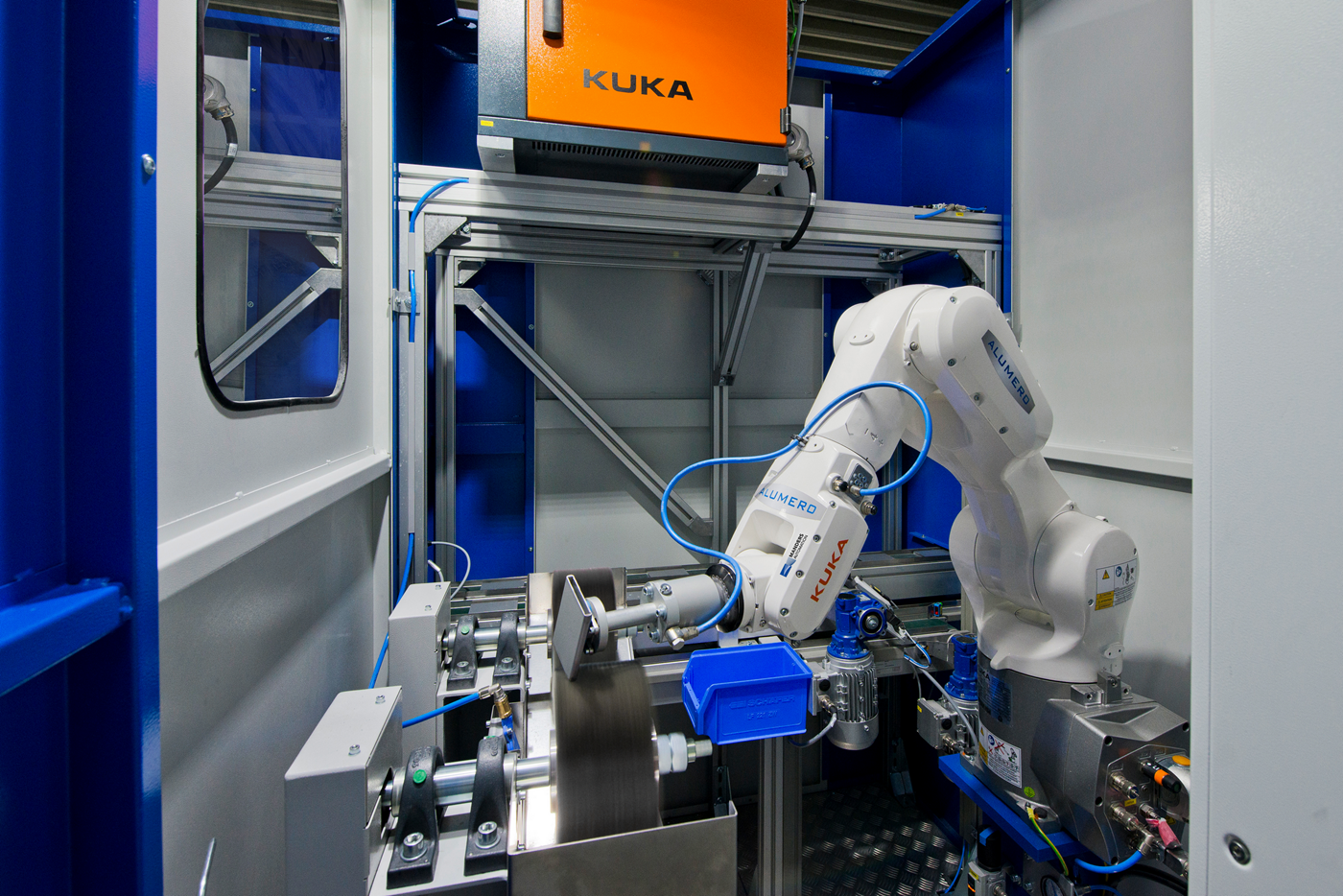

Automation solution with KUKA robot increases productivity and ensures quality

One of FINEX's customers is Secrid, a Dutch company that focuses on pocketware and develops distinctive cardholders and wallets. This company has a decorative product with a unique Dutch-Made, A-Product market positioning and a strongly cohesive supply chain. For Secrid it is extremely important that the aluminium end profiles are completely measured, unique and high-quality deburred. "The demand for pocket ware is increasing and as this is an A-brand, maintaining the quality is extremely important, regardless of the volume," says Jerome van Bussel. In order to guarantee the same high quality at a higher volume, FINEX had to automate its production.