The functions of KUKA.CNC Sinumerik

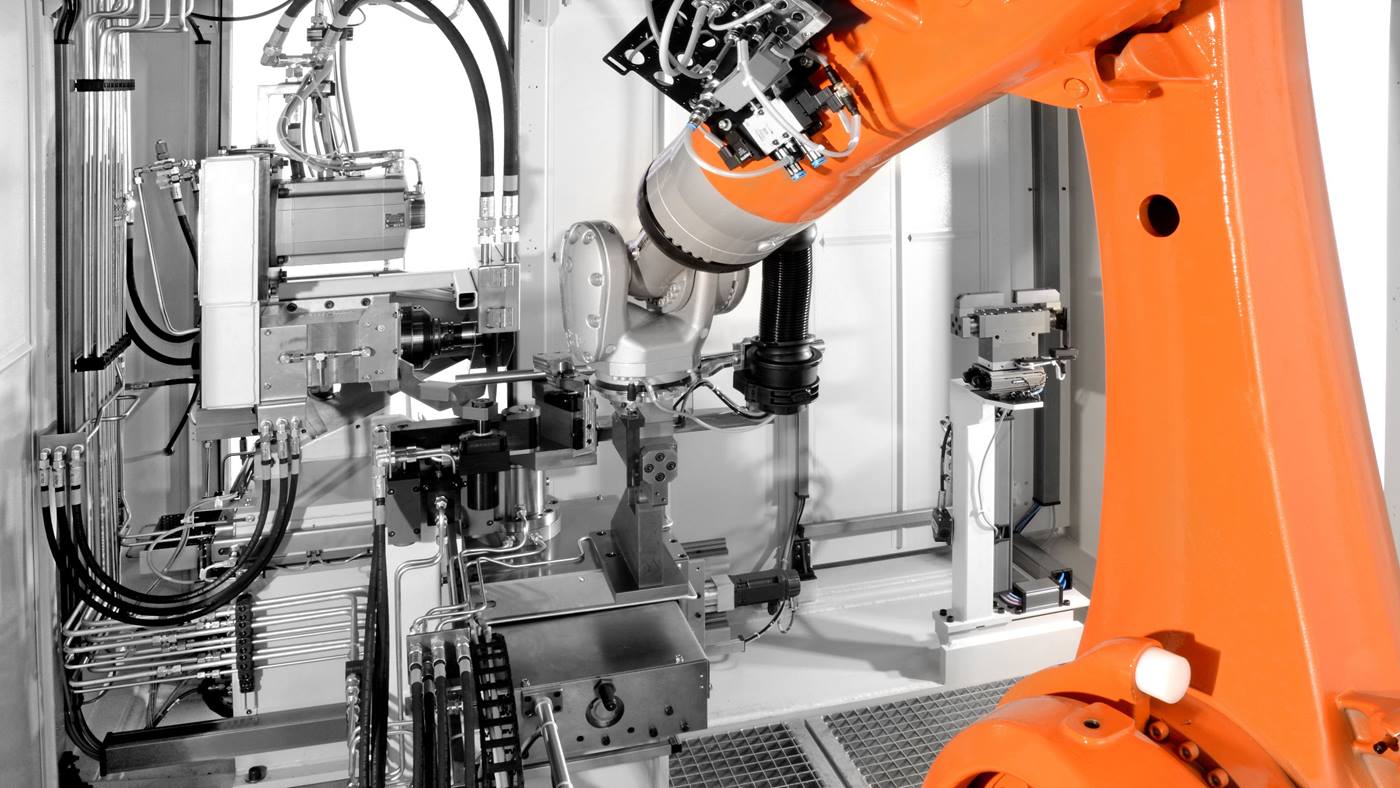

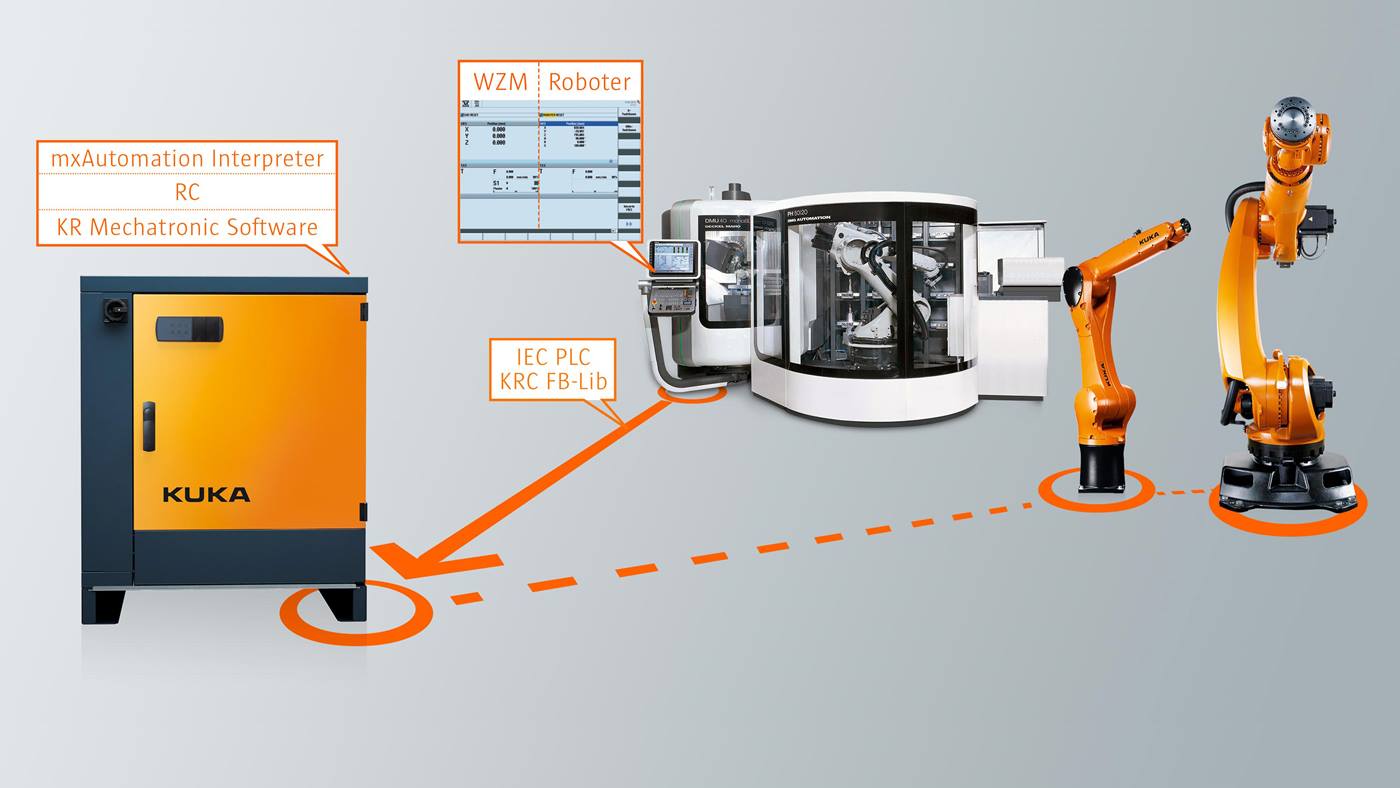

By using KUKA.CNC Sinumerik and a synchronized Profinet interface between a KR C4 controller and a Siemens Sinumerik 840D sl controller, it is possible to operate and control any given KUKA robot via the Sinumerik controller.

The Sinumerik 840D sl takes on the robot path planning tasks and provides the CNC operator who is familiar with Sinumerik with all known means of operating a KUKA robot using the Sinumerik operator control functions – for example, G-code programming and cycle programs.

Smart programming for the utmost path accuracy

The KUKA control system continues to use all control and drive functions which move the industrial robot on its programmed path as accurately as possible. To this end, the robot path interpreter uses a dynamic robot model which allows the robot to be optimally moved in its current pose. KUKA path and safety algorithms enable the safe operation of the robot, even in combination with a Siemens 840D sl controller.

Advantages of KUKA.CNC Sinumerik

- Robot connection to existing CAM systems

- Improved robot path performance

- Operator control of the robot using CNC expertise

- Optimum, standardized solution using SINUMERIK Operate

- Straightforward integration of the system into the machine network using SINUMERIK functions

System requirements for KUKA.CNC Sinumerik

- KR C4 robot controller

- X63 interface

- Siemens SINUMERIK 840D sl external controller

- KUKA System Software 8.3.9

- WorkVisual 3.0

- PROFINET 3.2