AI real lab: KUKA paves the way for the factory of the future

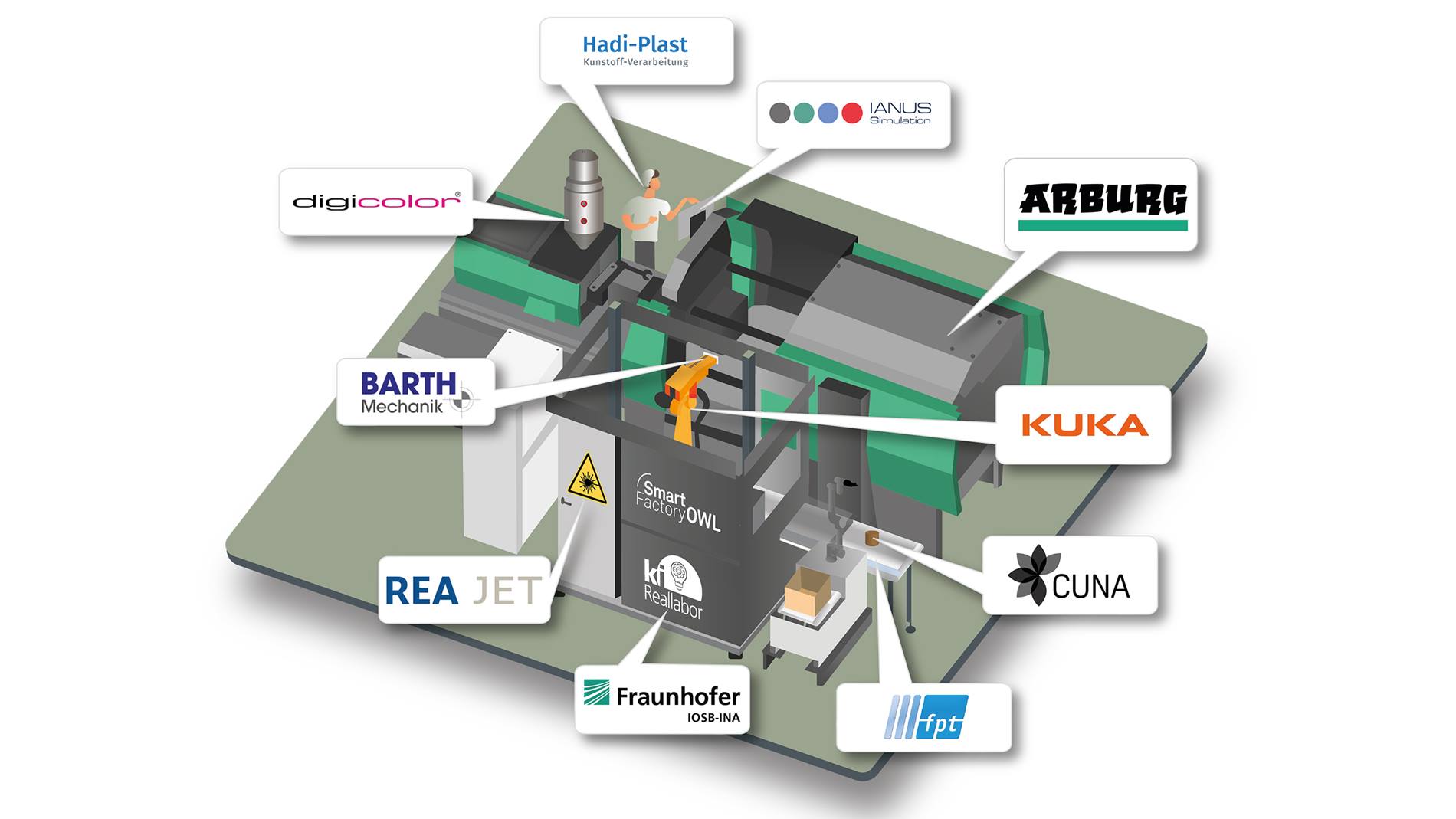

Leveraging the potential of artificial intelligence: This is the goal of a cooperation of ten partners initiated by Fraunhofer IOSB-INA. The basis for this: data from a real laboratory. In June, production of what is probably Germany's smartest cup starts at the SmartFactoryOWL – with a KR CYBERTECH from KUKA. This not only takes plastics production a step further, but also provides a glimpse of the factory of the future.

18 June 2021

Smart cup is created in the real lab

To this end, the AI real lab collects data streams from systems and processes and makes them freely available to AI developers and companies on a platform. In June, the SmartFactoryOWL will become an experimental field: The fully networked and AI-supported production of a reusable cup made of a biological plastic that does not require any petroleum will start. The special feature: Not only is the material used for production made from renewable raw materials sustainable, but so is the recycling cycle specially organized by CUNA Products GmbH.

Nissrin Perez, project manager of real production at Fraunhofer IOSB-INA, is also convinced that the open data basis means great progress for the German plastics industry. Even more: "We want to understand and localize errors and causes in production processes. For this, components and plants need a common, interoperable language. The basis for this is laid by the data streams that we will collect in the future as part of 'Collaborative Condition Monitoring'."

Technological use cases give us valuable experience to drive Industrie 4.0.

About Fraunhofer IOSB-INA Lemgo: Fraunhofer IOSB-INA was founded in October 2009 as the industrial automation site of the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation. The Lemgo site with its current 95 employees focuses on systems engineering for intelligent automation systems in the fields of intelligent sensors, industrial communication, cyber security, big data, machine intelligence and human-machine interaction.