What is additive manufacturing and how does it work?

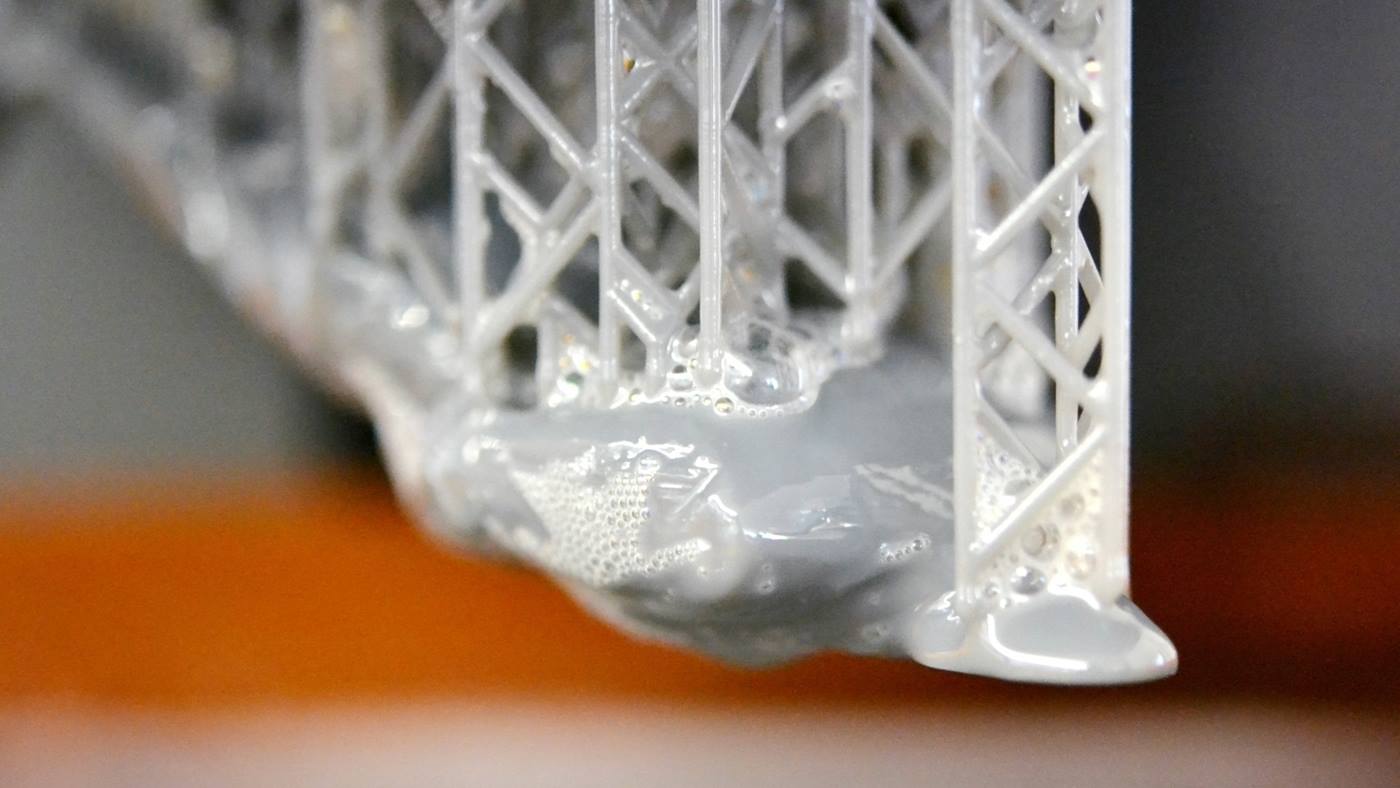

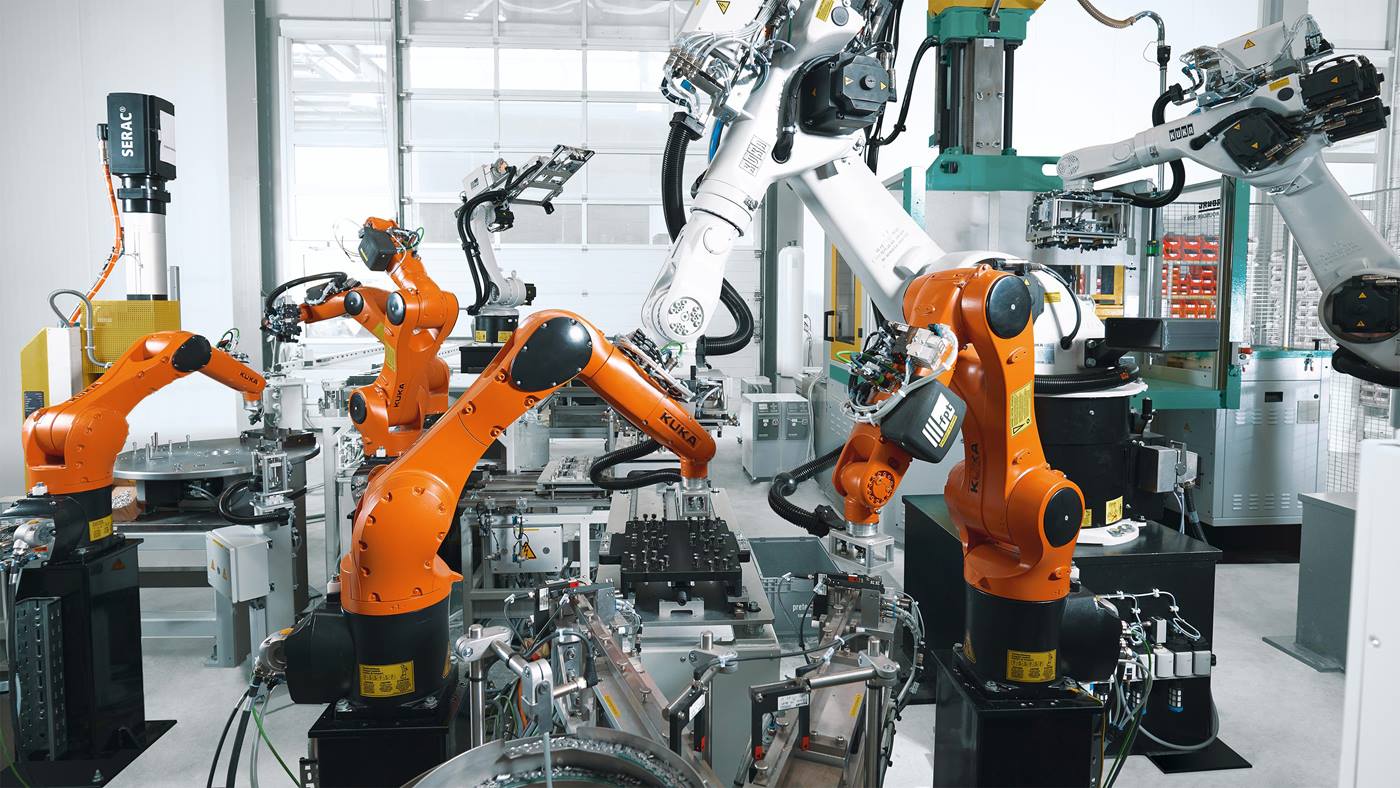

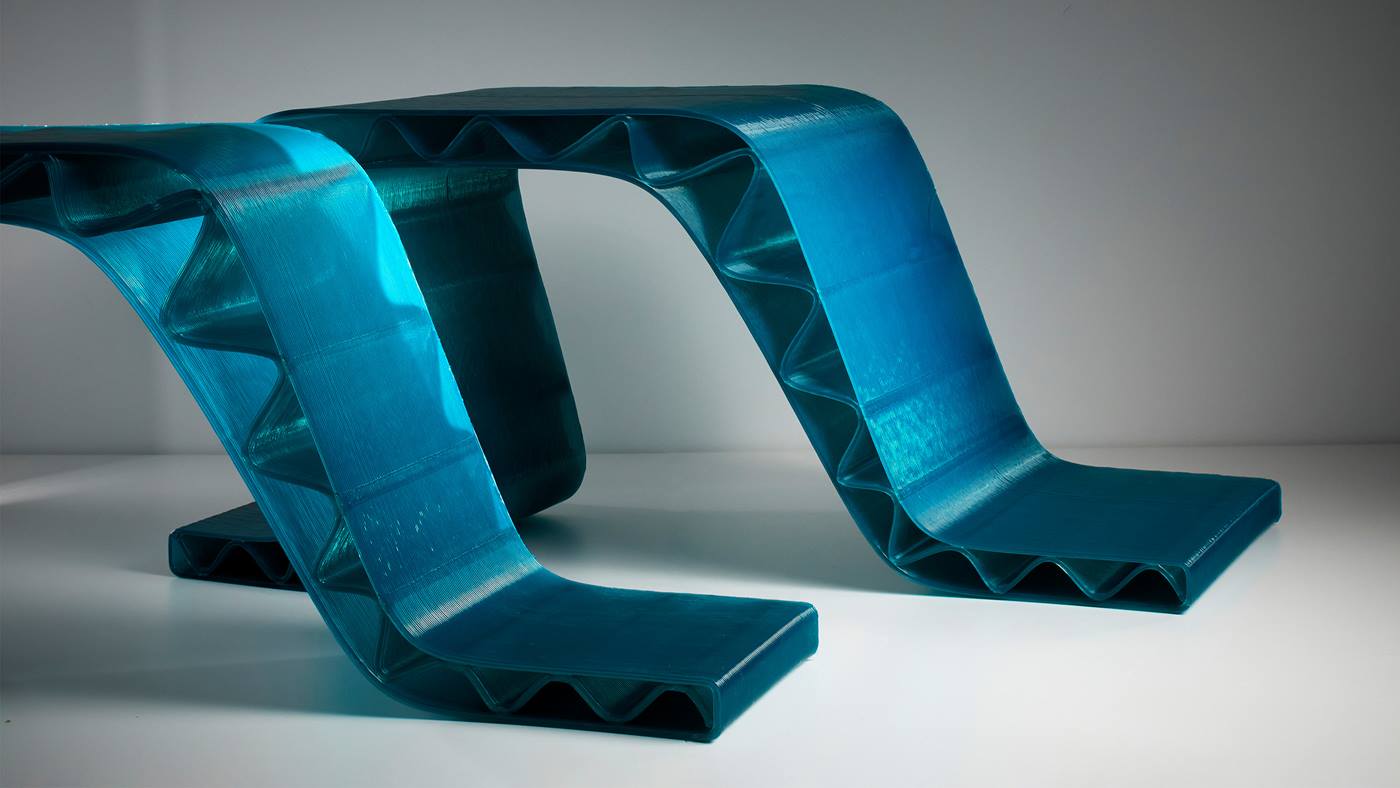

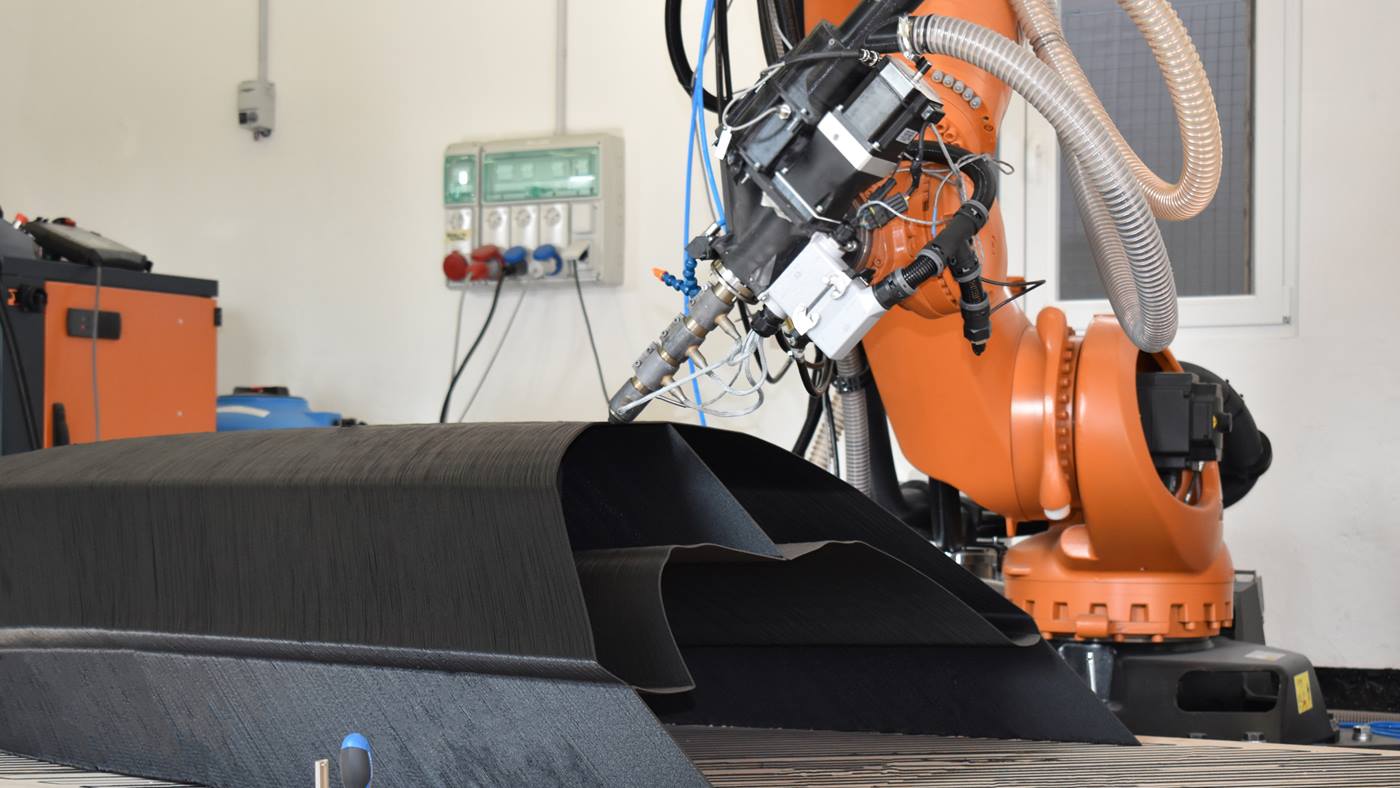

In the case of additive manufacturing, also known as 3D printing, components of all different shapes, sizes and structures are manufactured by the precise application of meltable material in layers in accordance with digital design data layer by layer. 3D printing processes – including Selective Laser Melting (SLM), Fused Deposition Modeling (FDM) and Binder Jetting – can be used, in particular, for the fast, precise and inexpensive production of workpiece prototypes or small series.