Features of the KUKA.LaserTech software

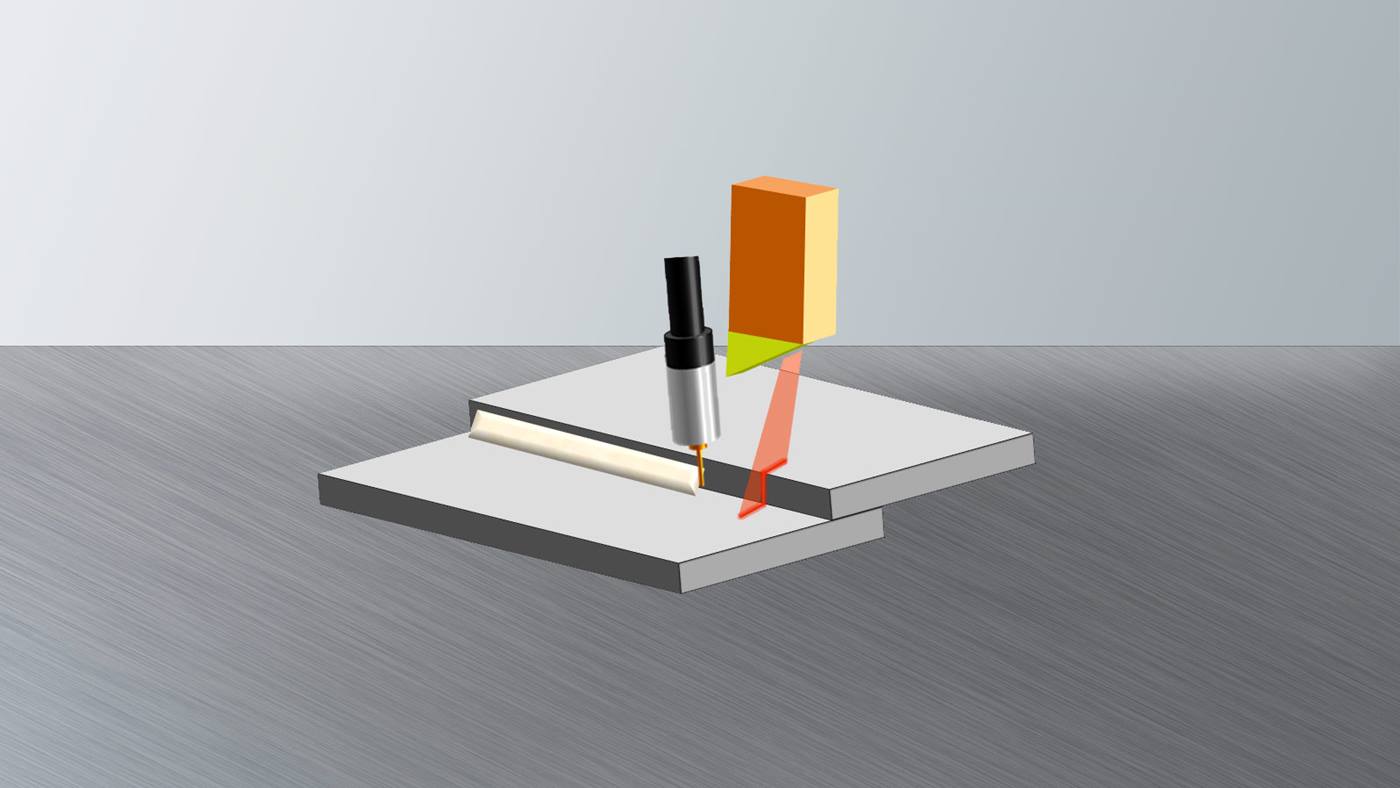

Welding, brazing, soldering or cutting – you name it: KUKA.LaserTech is a versatile software solution for various laser applications that allows you to achieve the highest degree of flexibility.

KUKA.LaserTech has a modular structure. The user-friendly inline forms ensure that laser applications can be integrated and programmed quickly and easily.

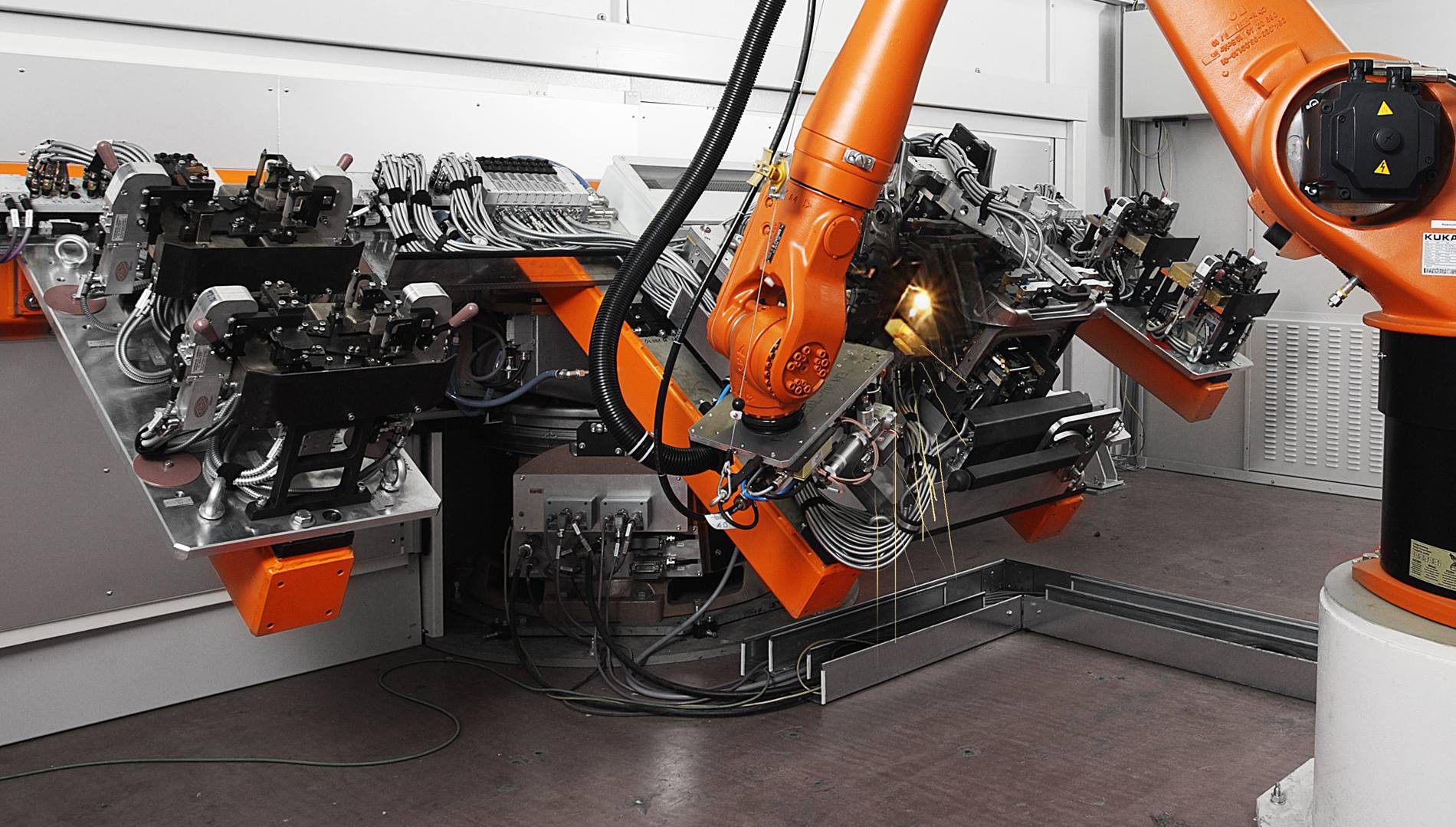

Video: KUKA robots make laser welding flexible

One of the most advanced and flexible laser welding cells in Europe can be found at WinNova (formerly Innova) in Laitila (Finland). WinNova is a research and training company and receives orders from the shipbuilding industry on a regular basis. To enable WinNova to work with the large and bulky components prevalent in this industry, KUKA developed the high-tech laser cell, Innova Lasepro, which paves the way for flexible, camera-monitored laser welding and laser cutting processes.

System requirements for KUKA.LaserTech

Software

System Software KSS 8.2 or KSS 8.3

Hardware

- KUKA robot controller KR C4

- Field bus systems (EtherCat, ProfiNet, Interbus, Profibus, etc.)

- All KUKA robots with KSS System Software, KUKA High Accuracy robots are recommended for a great many applications

- Laser source and processing optics (customer-specific adaptations may be possible in consultation with KUKA)

Advantages of laser applications with KUKA robots

- Economic feasibility of highly flexible system concepts

- Workspace maximization by means of open 6-axis kinematic system, expandable using KUKA positioners and linear units

- Intelligent automation concepts by way of system linking