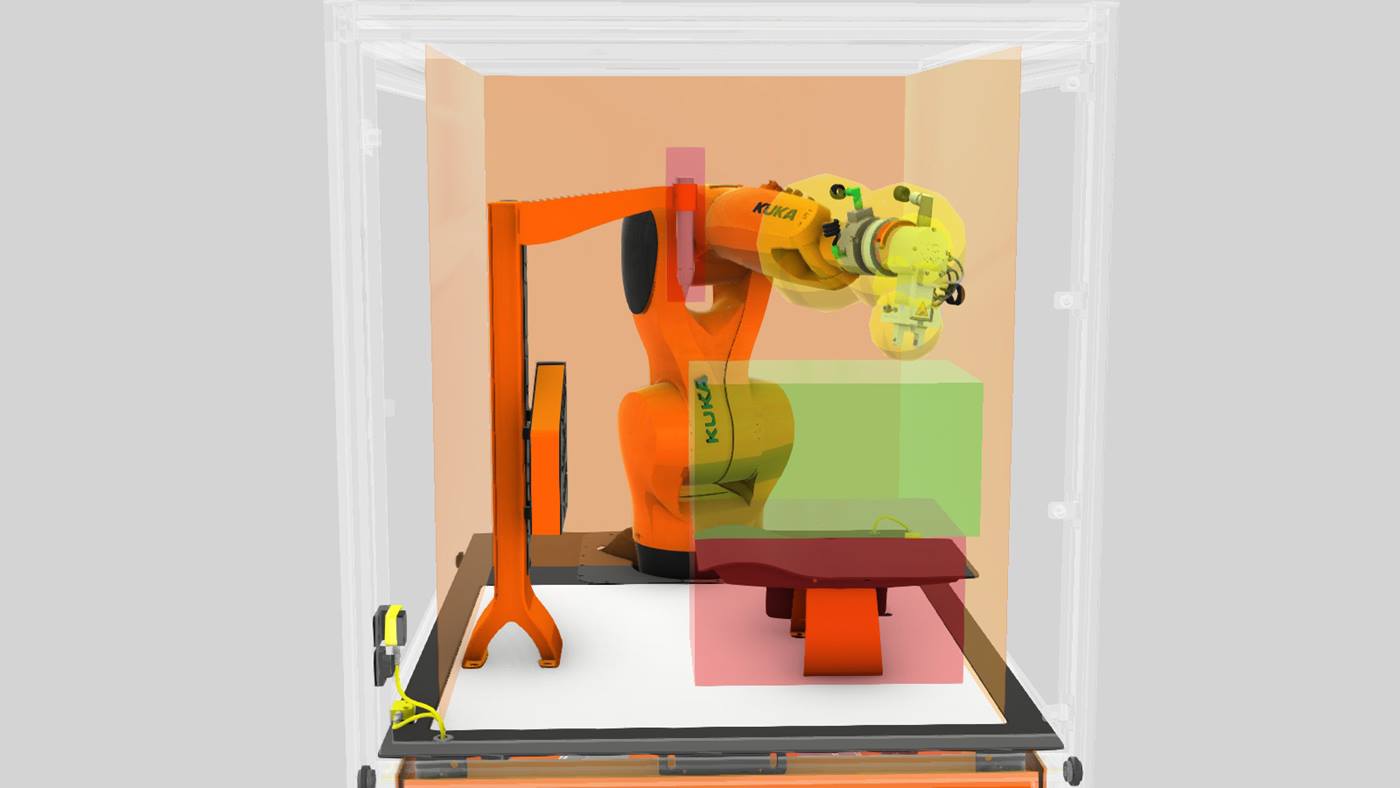

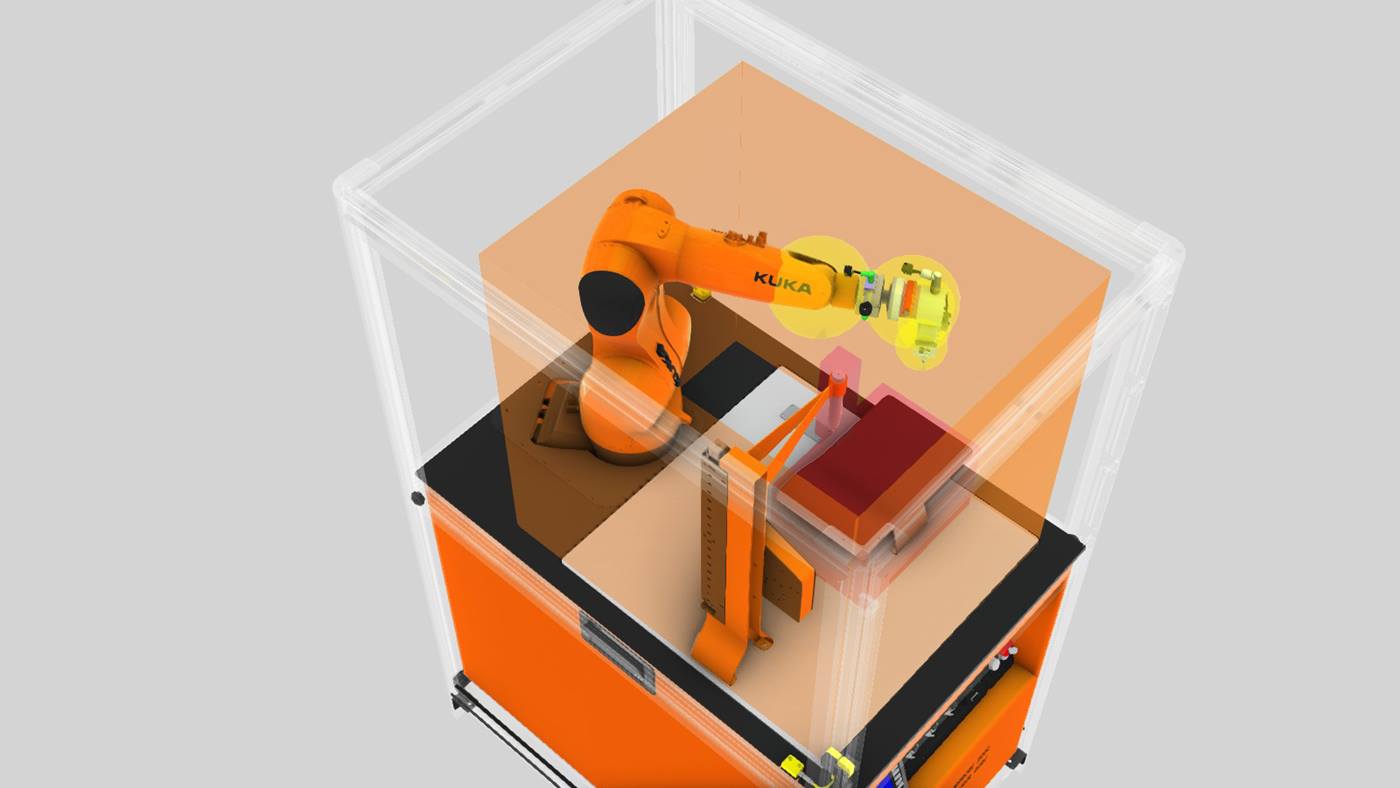

Monitoring spaces with KUKA.SafeOperation

The emphasis is on safety. The software package provides up to 16 monitoring spaces and a fixed cell area for safe reduction of the theoretical workspace – the definition of these monitoring spaces determines the response of the robot.

Each area can be defined individually. Choose between Cartesian and axis-specific definition. A further distinction is made between these types of space:

- Workspace

- Protected space

- Alarm protected space (non-stopping)

- Alarm workspace (non-stopping)

- Cell area (non-switchable)