หุ่นยนต์ในอนาคตจะต้องคล่องตัวและเป็นอิสระ

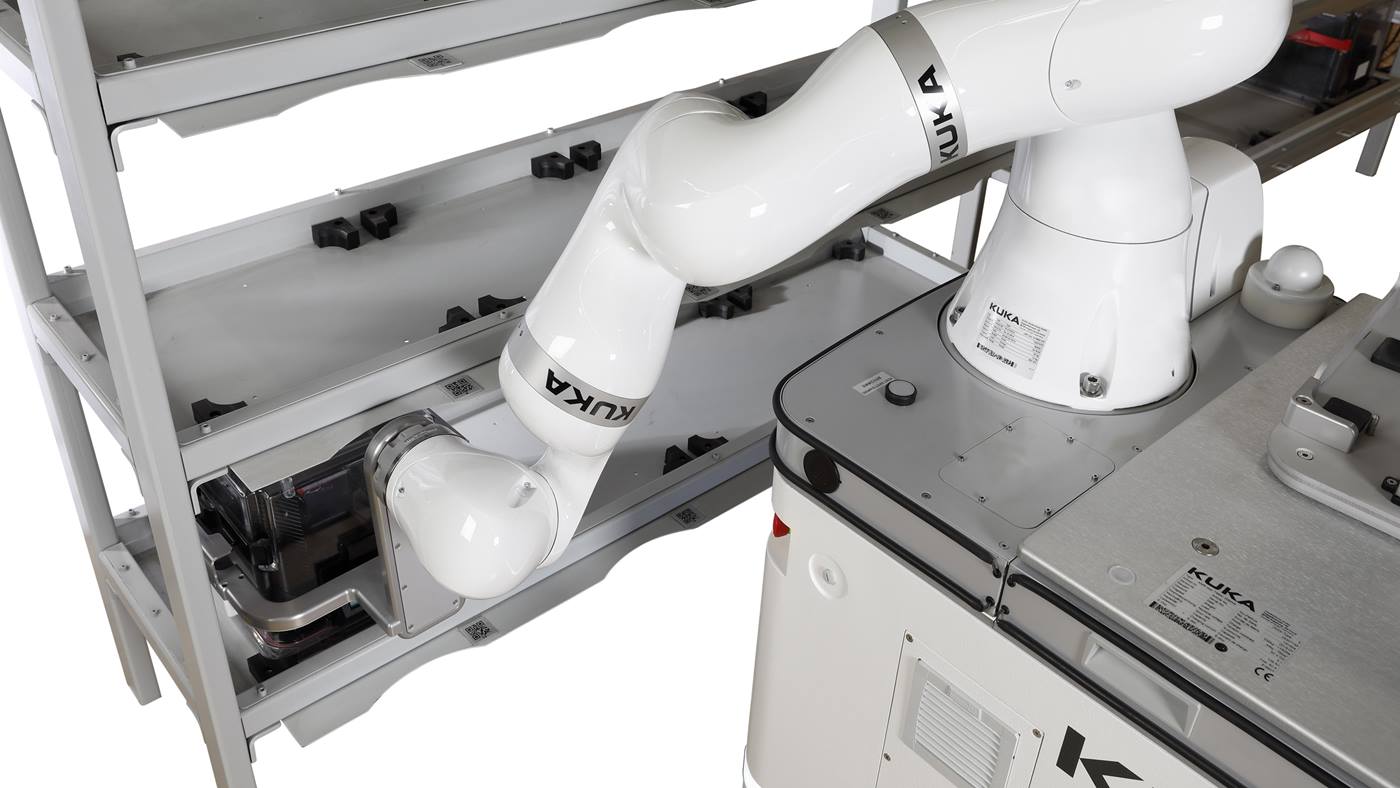

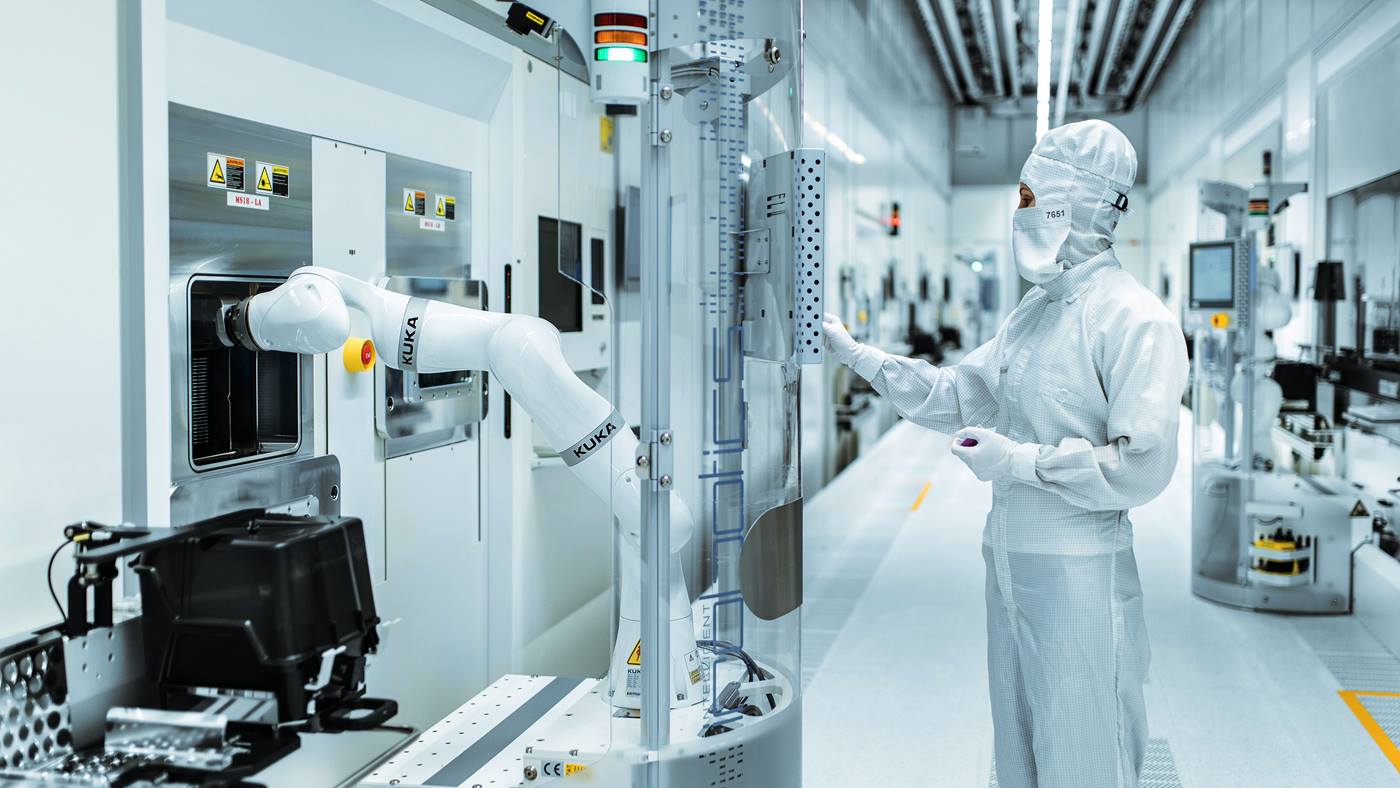

ระบบเซ็นเซอร์ขั้นสูง การตั้งโปรแกรมแบบไม่ต้องเขียนโค้ดและเทคโนโลยีแบตเตอรี่ที่ล้ำสมัย รวมถึงความหนาแน่นของพลังงานที่สูงขึ้นช่วยให้หุ่นยนต์ที่เคลื่อนที่ได้อย่างอิสระสามารถนำทางได้อย่างอิสระ ตรวจจับสิ่งกีดขวางได้อย่างปลอดภัย หลีกเลี่ยงสิ่งกีดขวาง และสร้างเส้นทางอื่นได้ หุ่นยนต์ของ KUKA ทุกตัวติดตั้งแบตเตอรี่ชนิดลิเทียมไอออนที่ล้ำสมัย ซึ่งพร้อมใช้งานตลอดเวลาในโหมดการชาร์จแบบเหนี่ยวนำ ทั้งนี้เพื่อให้มั่นใจถึงการทำงานที่เสถียรอย่างต่อเนื่องของหุ่นยนต์เคลื่อนที่ของเรา ผลลัพธ์ที่ได้คือ การทำงานทุกงานตลอด 24 ชั่วโมงและความพร้อมใช้งาน 99%

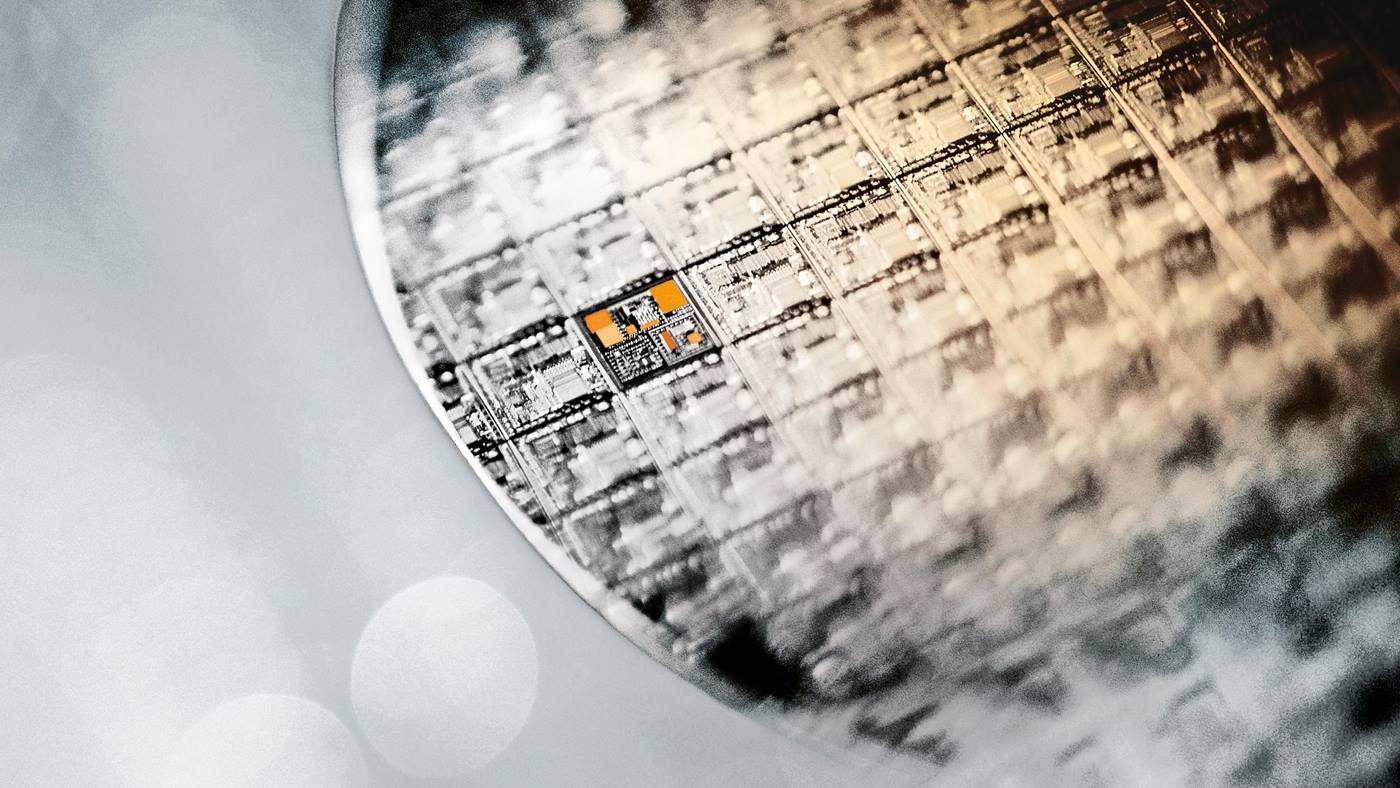

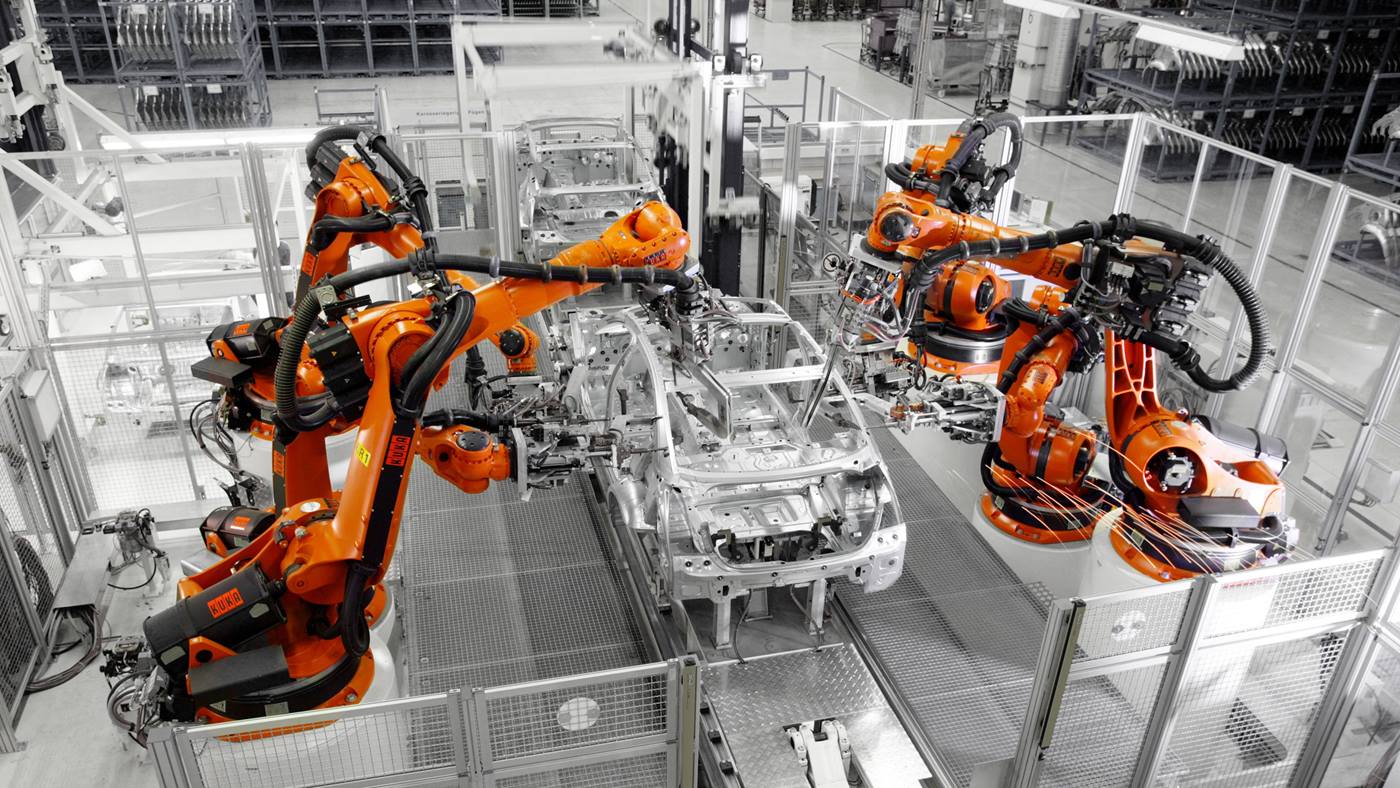

ความสามารถในการเคลื่อนไหวที่ไร้ขีดจำกัดช่วยเปิดโอกาสใหม่ ๆ ในการใช้งานให้กับหุ่นยนต์ มีการใช้งานหุ่นยนต์ในอุตสาหกรรมหลายประเภท รวมถึงคลังสินค้า การผลิต การดูแลสุขภาพ และการค้าปลีก