Customized mass production

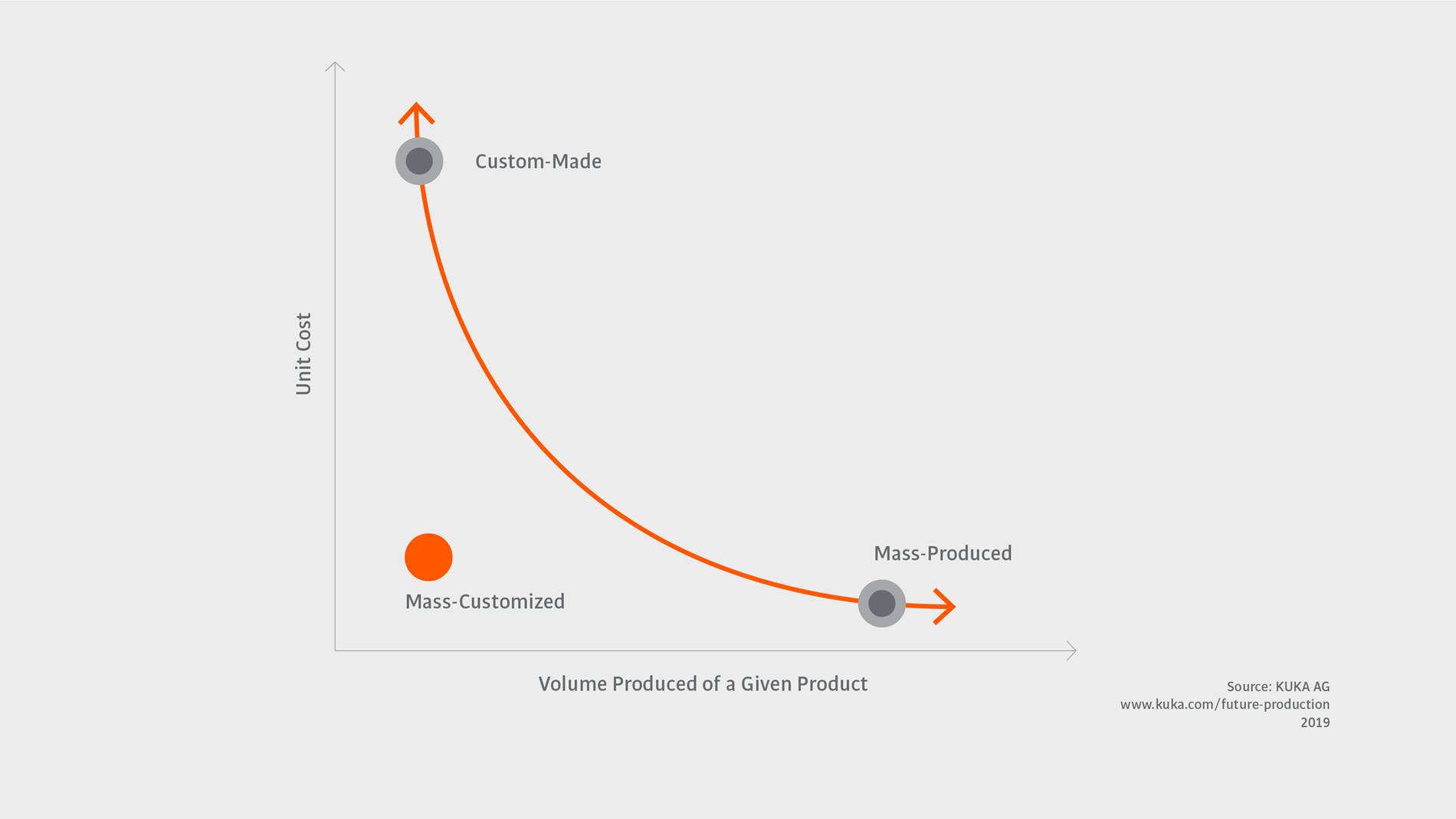

To satisfy individual customer requests while remaining cost-efficient, it is essential that companies develop customer-focused business models and employ intelligent, versatile production technologies.

Maintaining overall plant efficiency is the objective of customer-oriented mass production (mass customization). The critical factors of availability, performance and quality must not drop to a level lower than that of normal series production. In addition, an attractive return on investment and the quickest possible time to market for new products and product variants must be ensured.

The key to this lies in establishing high levels of standardization and automation which also provides scope for variations on customer-relevant product features. What’s more, the concept of modularization, which gives customers the opportunity to configure products on the basis of a modular system, is a cost-efficient way of satisfying individual customer requests in high quantities and with a high level of quality.