Scalable, flexible, efficient.

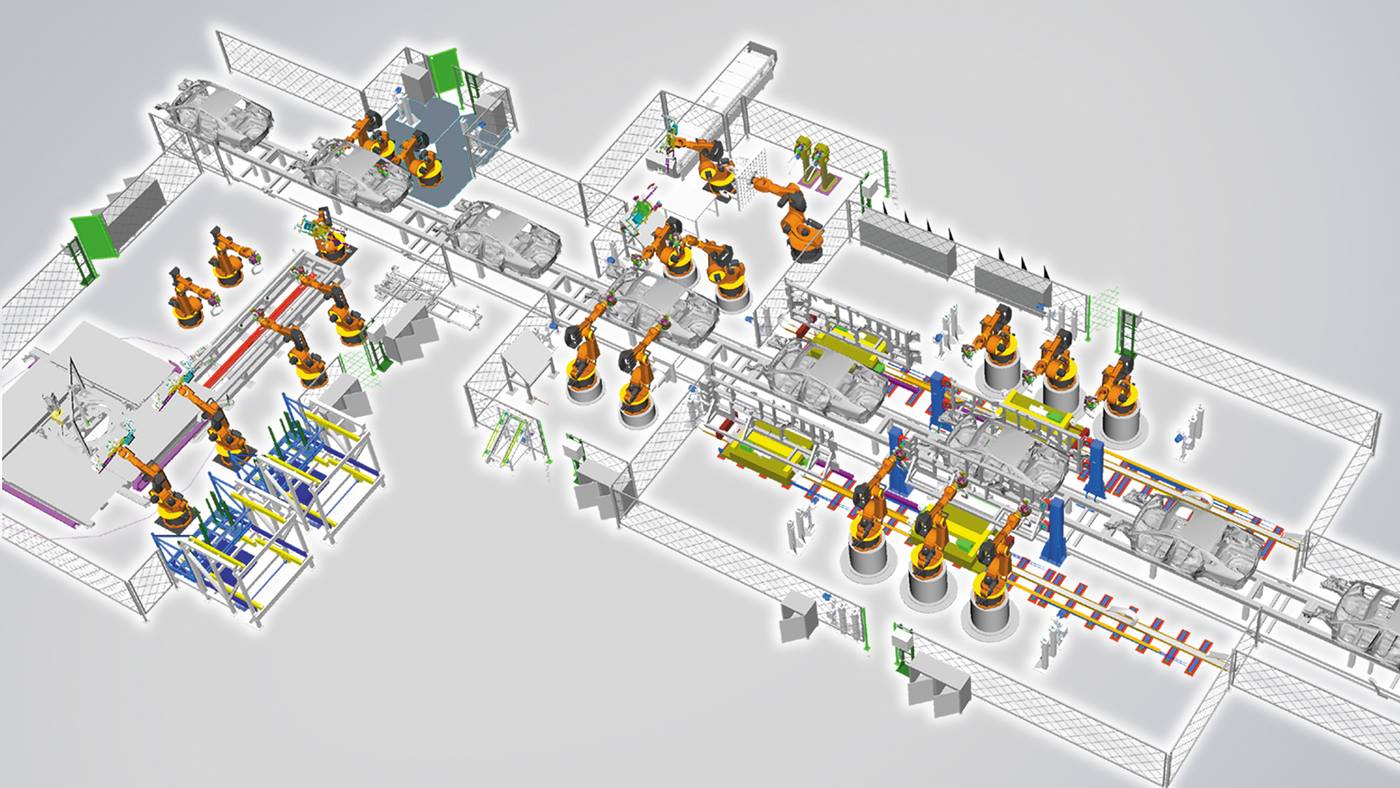

KUKA is widely known as a robot manufacturer – but we have just as much competence in the conception, planning and implementation of production systems. We are experts in system integration – be it for an individual production cell or a complete production system.

Please do not hesitate to contact us, we will find the right production solution for every sector.