Robotics for electronics production: Perfectly adapted to market requirements

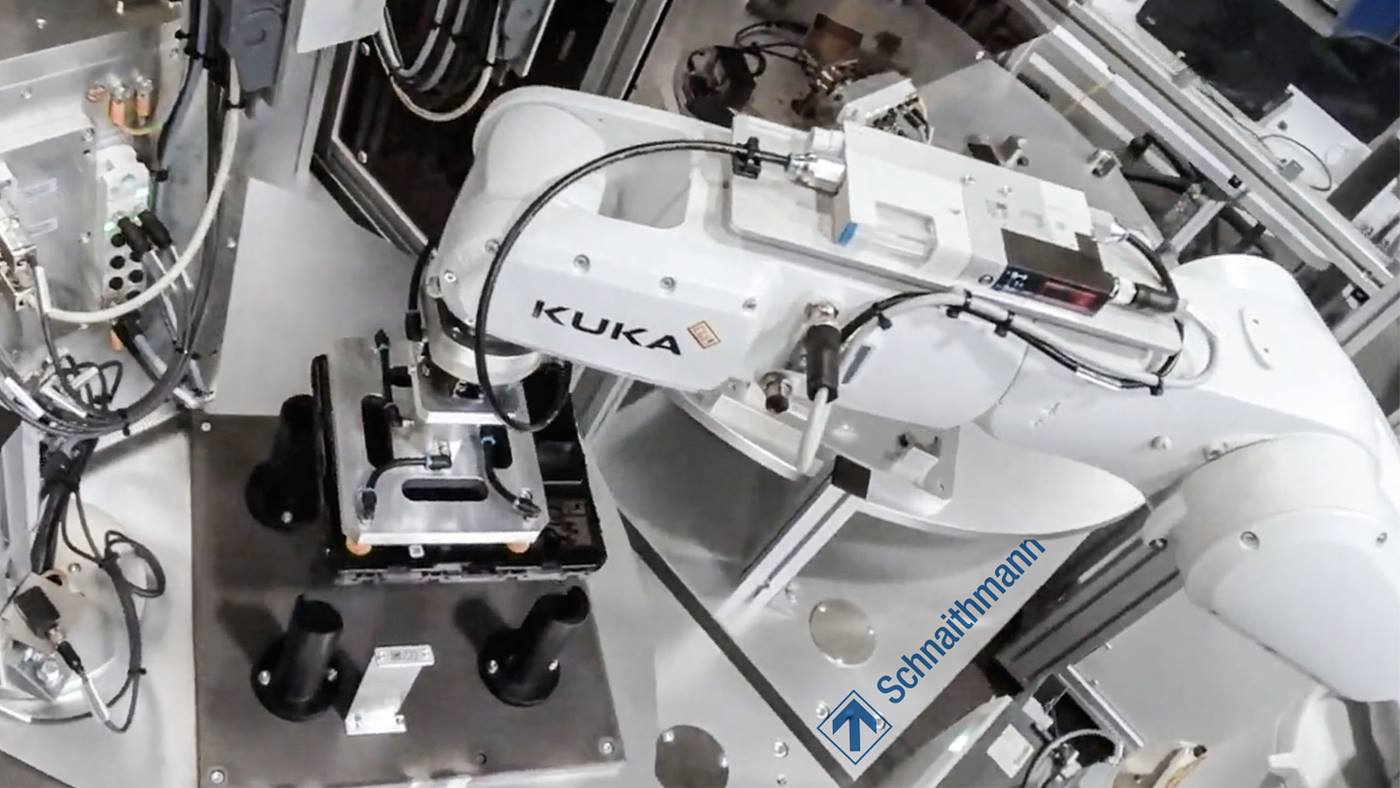

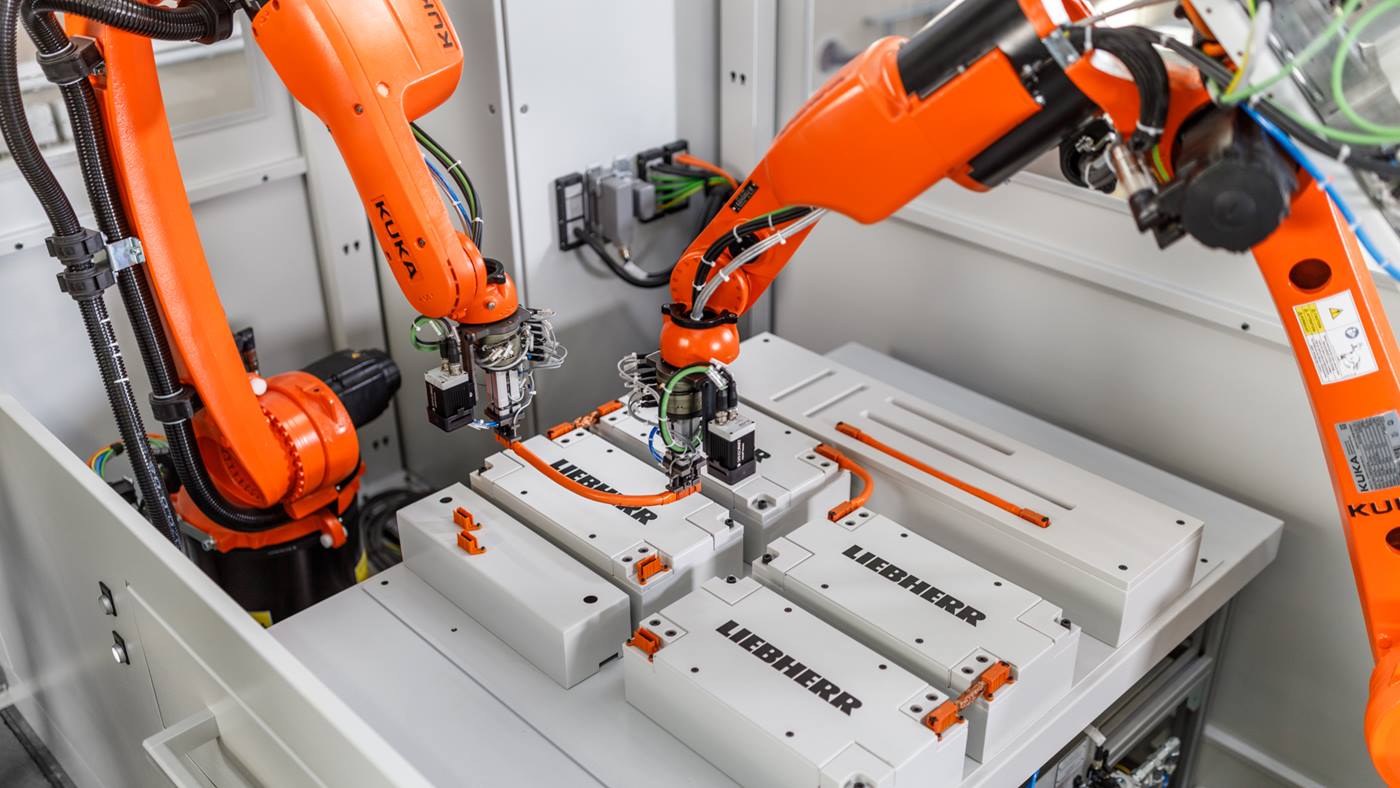

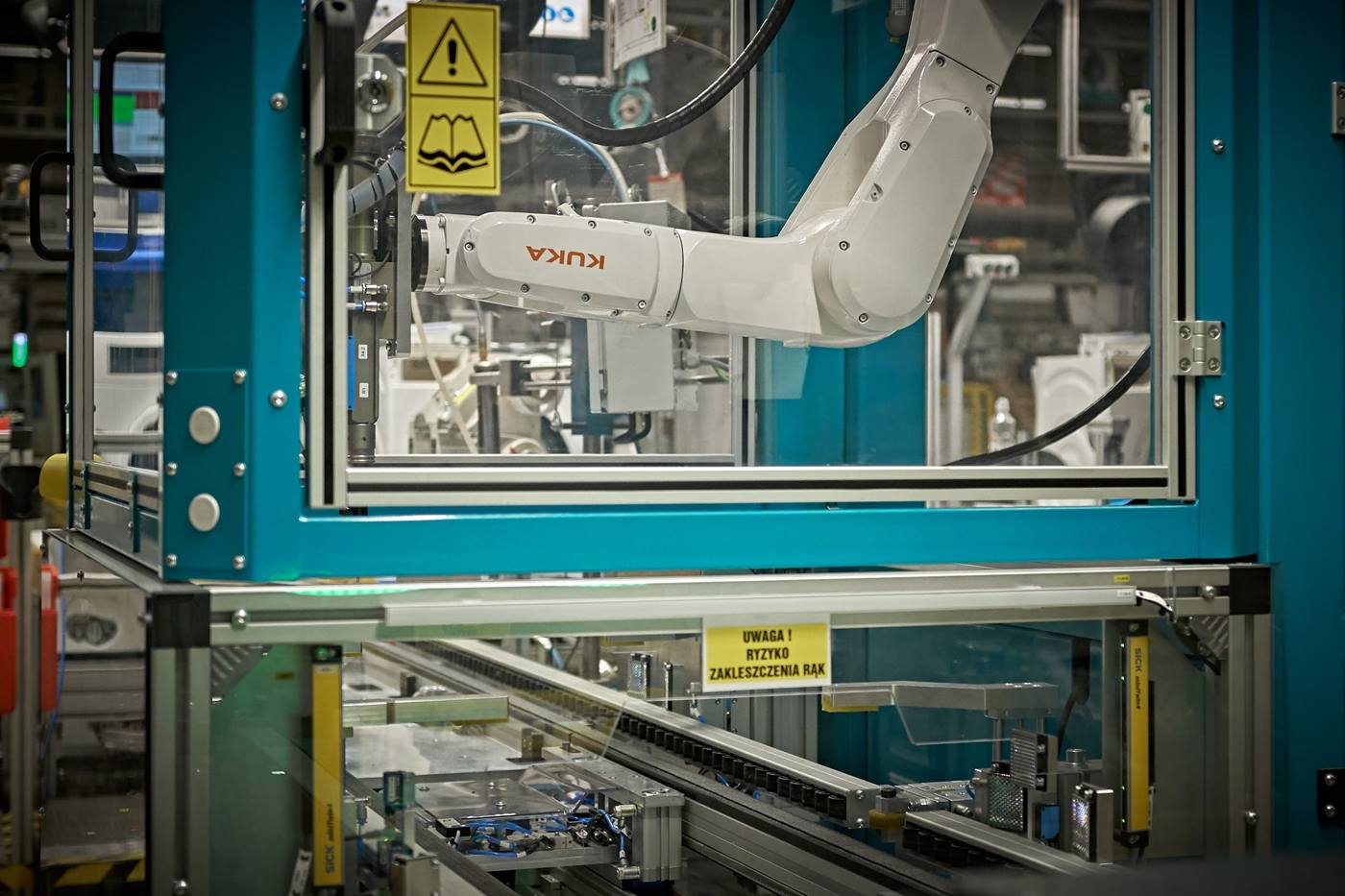

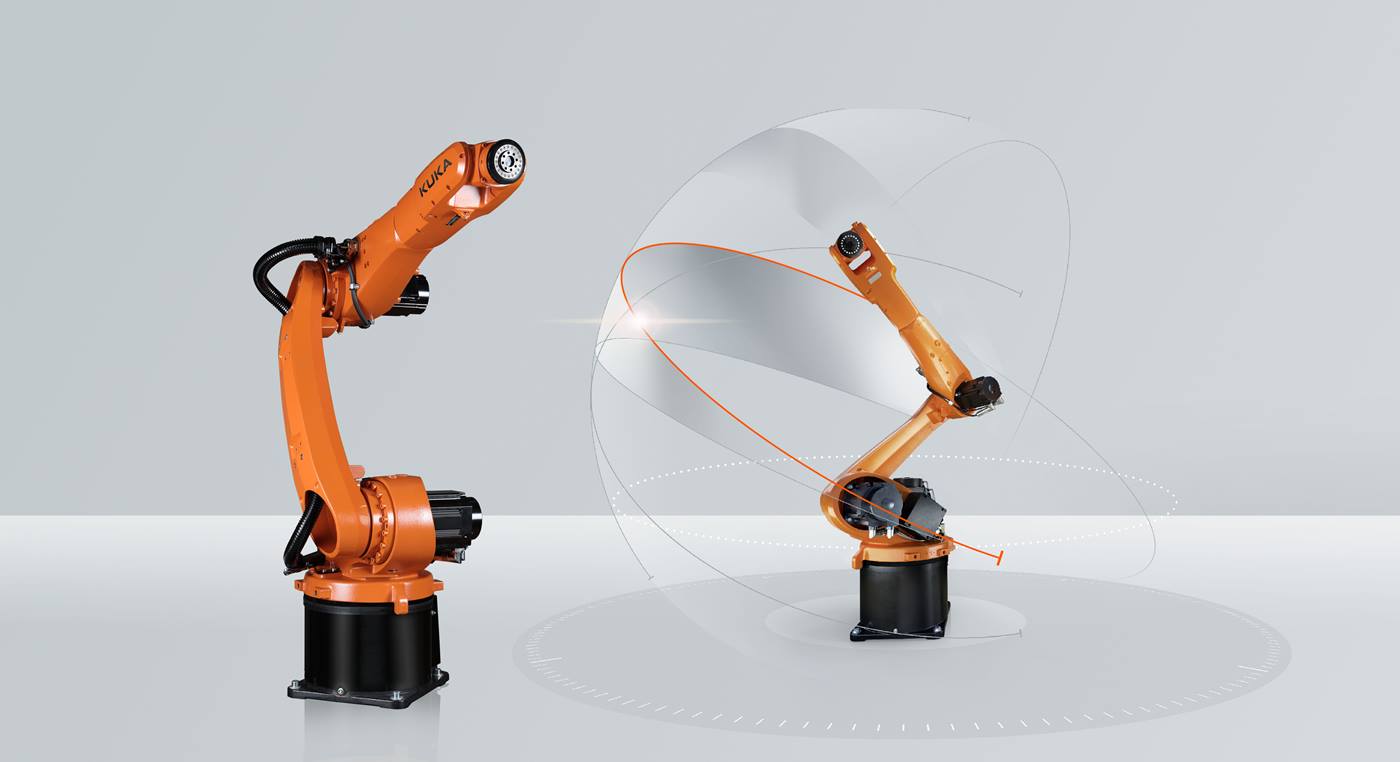

In view of the increasing demand for electronic devices and the growing shortage of skilled workers, the automation of electronics manufacturing processes is indispensable. By using robots, production processes can be adapted both flexibly and easily to meet the rapid changes in the market.

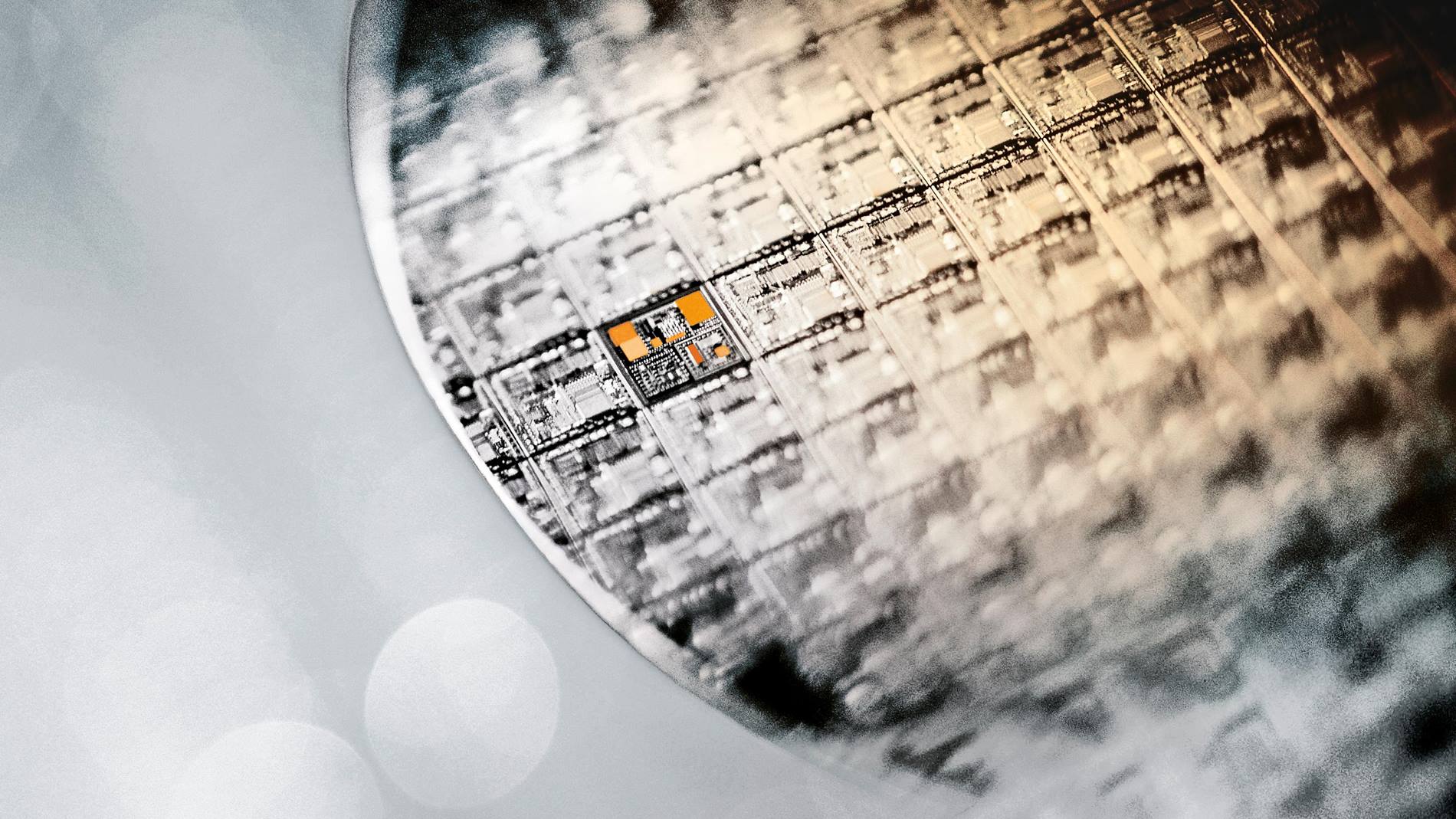

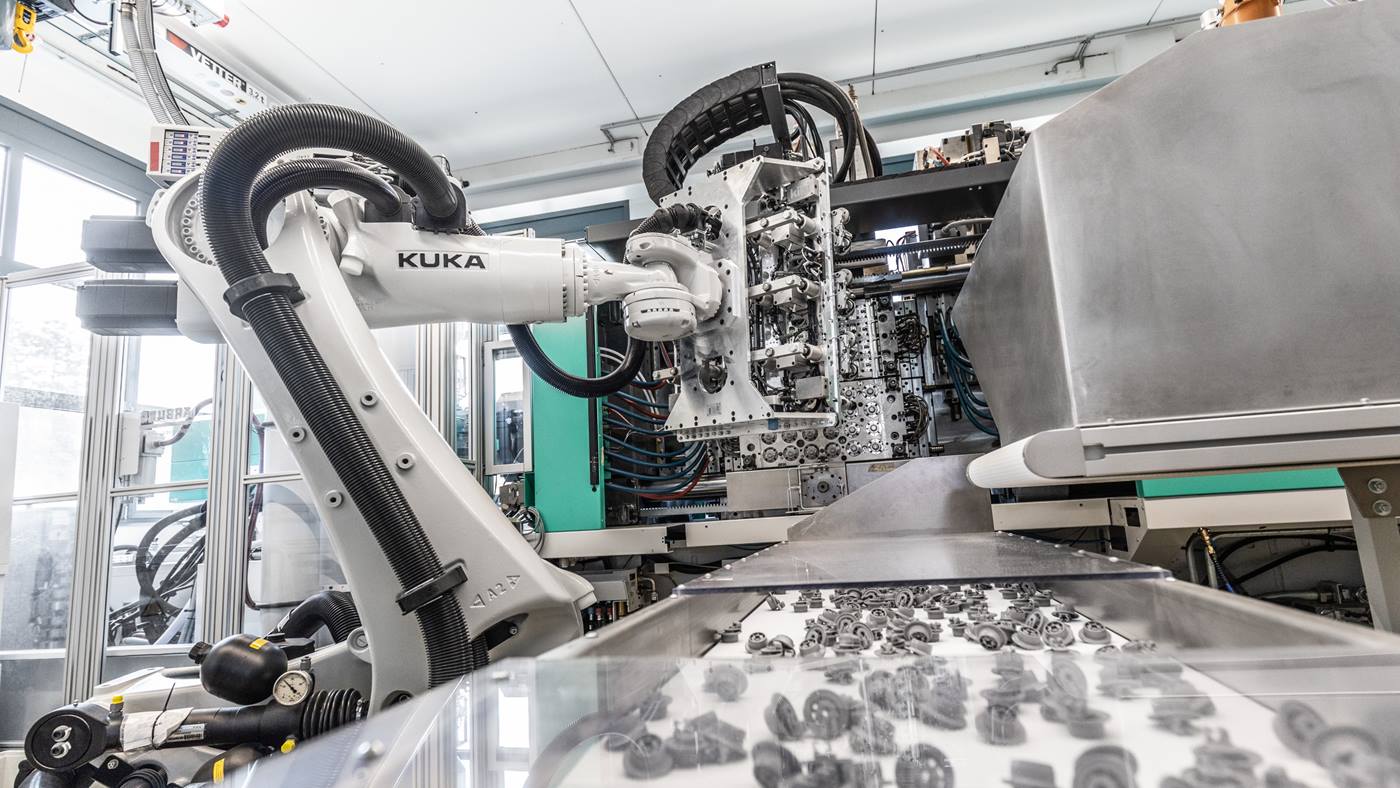

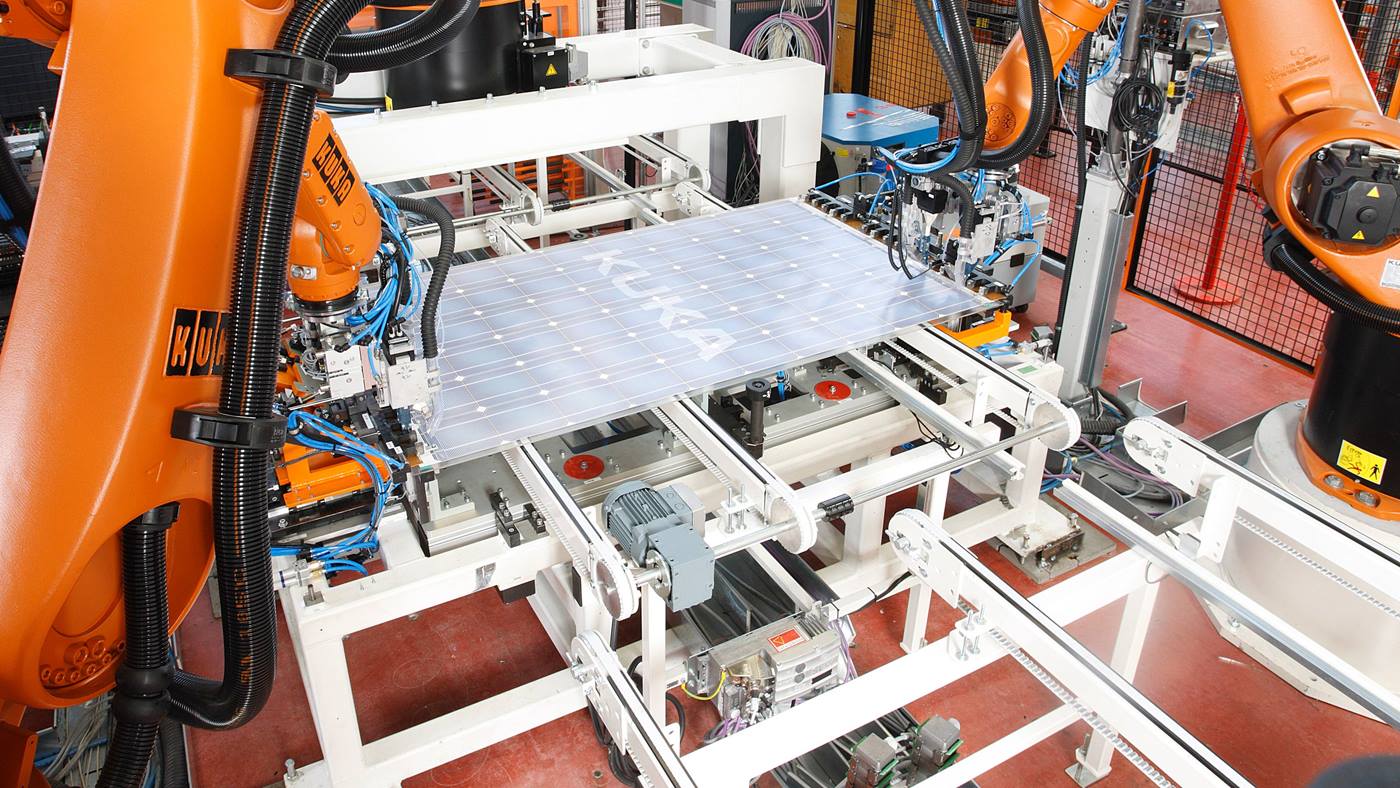

Together with our partners, we develop agile automation solutions that are perfectly tailored to key industries such as semiconductor manufacturing, automotive electronics and the 3C entertainment industry. Our robots are specially designed for clean and dry rooms, are ESD-protected as standard, and offer a high standard for handling sensitive electronics. The compact yet high-performance KR C5 micro small robot controller enables our robots to be optimally integrated, even in small spaces, offering our customers maximum flexibility.