opsira GmbH is producing innovative goniophotometers using KUKA robots

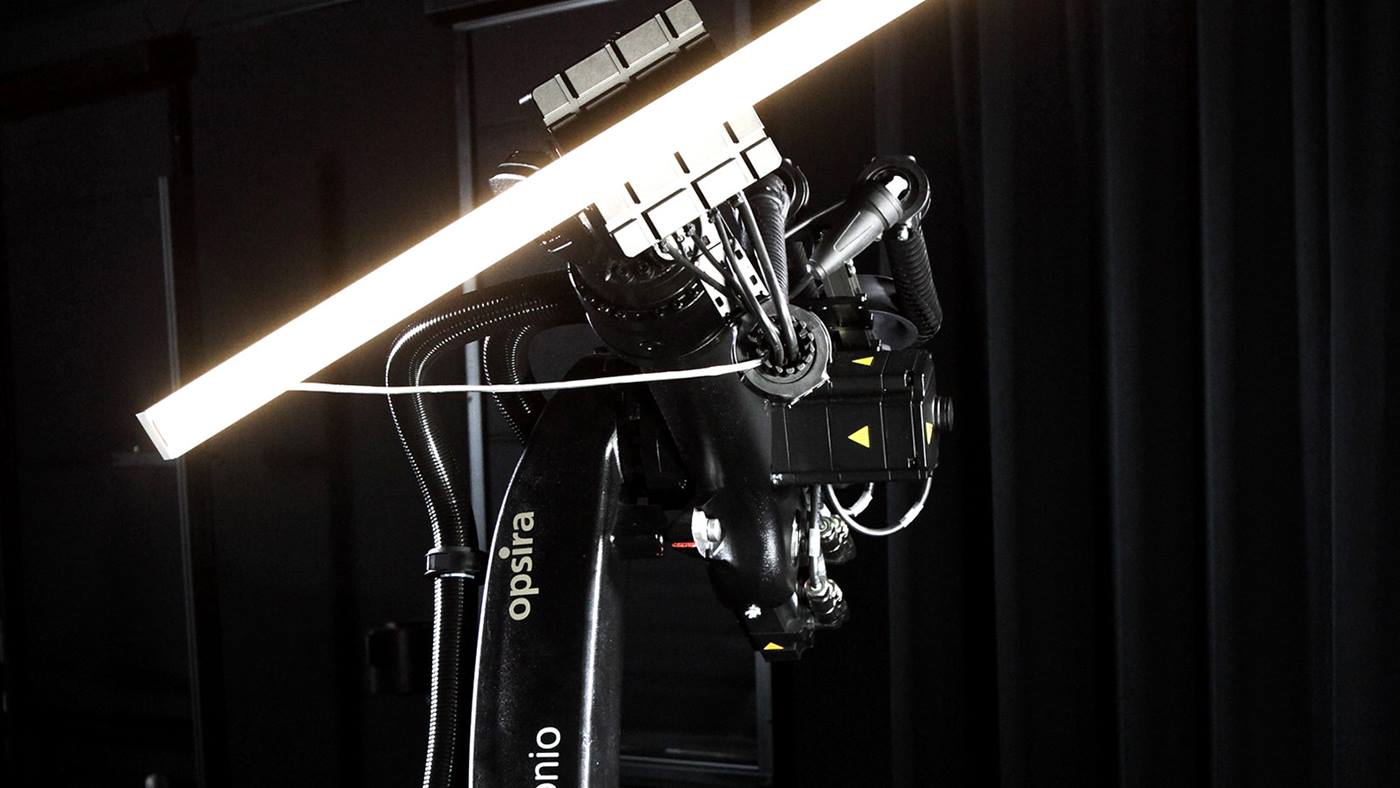

The multi-functional “robogonio” light meter: that is what opsira GmbH – based in Weingarten, Germany – placed on the market about three years ago

Named by fusing the words “robot” and “goniophotometer” together, the robogonio measures the angle-dependent light intensity distribution of a light source or luminaire and combines the advantages of industrial robotics with modern light measuring technology. Since 1999, opsira has been a full-service provider for the optics and lighting industry and currently has 16 employees. With “robogonio”, opsira is strengthening the business unit for measurement systems.

Requirements for goniophotometers have increased

In lighting technology, goniophotometers are the standard measurement method and have now been in use for over 100 years. The conventional design comprises the mechanical goniometer configuration with a horizontal and vertical axis for rotating the test item (e.g. a front headlight of an automobile) as well as a photometer which measures the light intensity. In recent years, the requirements for goniophotometers have increased as photometric systems have become more complex and compact and as optical design tools have become more powerful."robogonio" combines several goniometer types

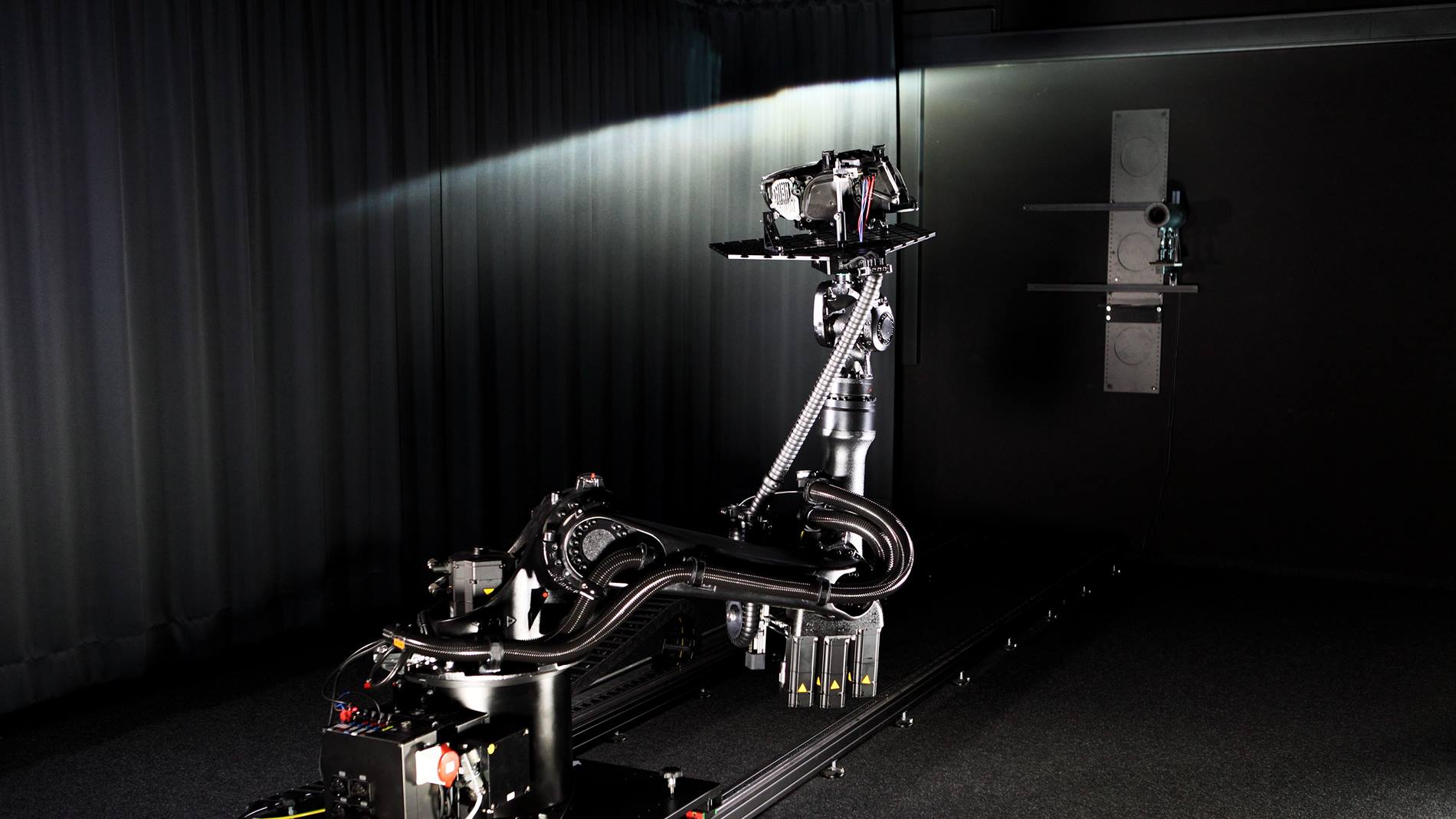

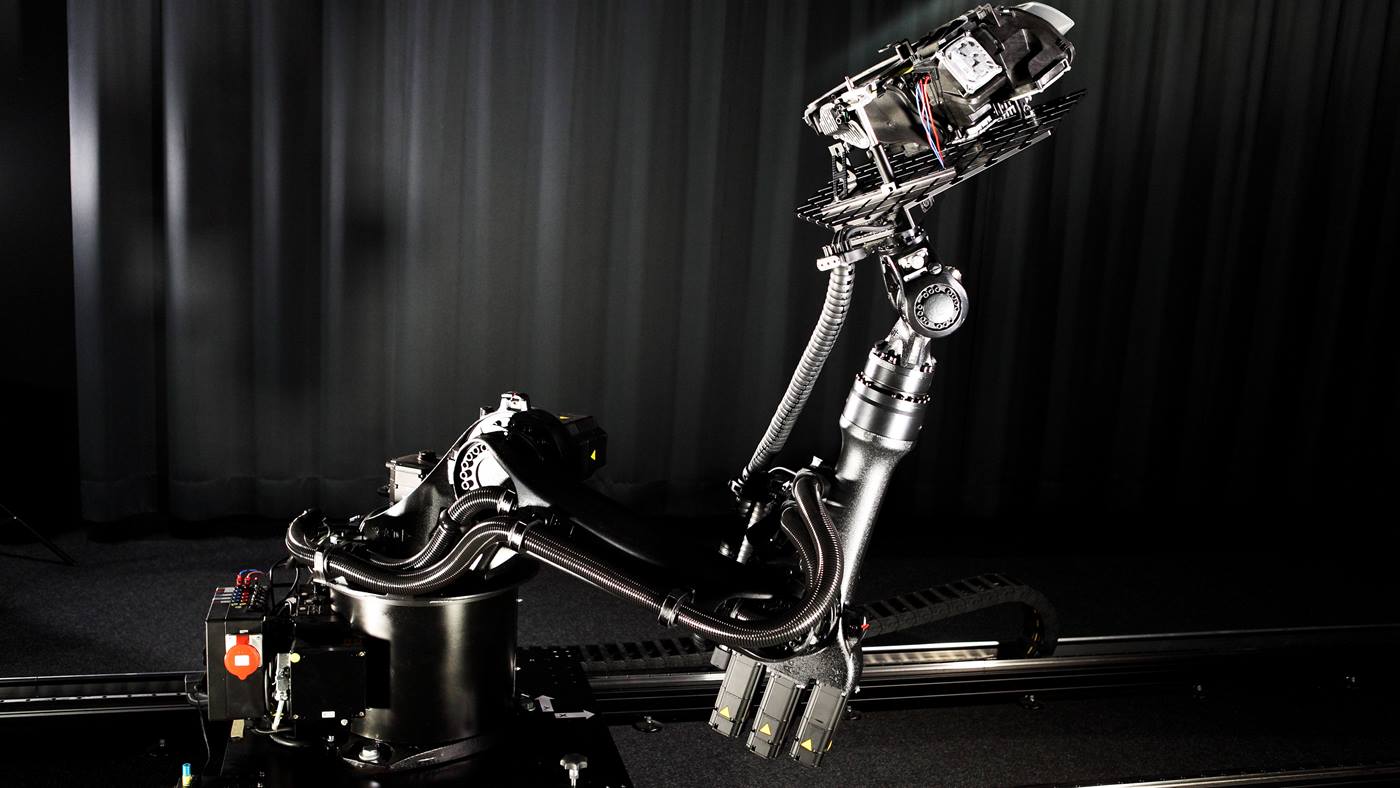

With “robogonio”, opsira is strengthening the business unit for measurement systems. In doing so, opsira relies on different KUKA robots of all sizes. This enables exact measurement of even the smallest LEDs, car headlights, traffic signals such as stoplights or railroad crossing signals, through to the lighting at takeoff and landing runways at airports. While traditional goniophotometers are very limited in their application and require different machines and test methods for near and far fields, the “robogonio” combines the advantages of different conventional goniometer types.The “robogonio” uses the robot’s six axes for the positioning of the test item as well as for angle manipulation that is highly precise and reliable. The high number of mechanical degrees of freedom enables measurements in the traditional A, B or even C planes using a measurement system and thus combines goniometer types 1.1, 1.2 and 1.3 into one device according to DIN EN 13032-1. Depending on the configuration, goniometer types 2.x, 3 are also possible. In concrete terms, the “robogonio” can thus measure light intensity and radiant intensity distributions (EULUMDAT, IES, etc.), color distribution or even luminance distribution (glare).

KUKA robots from small robots up to heavy duty

As a result of the decision for KUKA Roboter GmbH, opsira can offer its customers the entire product portfolio. The scalability ranges from solutions with the KR AGILUS small robot series through to the use of KR 6 and KR 30 robot types and on to the high payload range of the KR QUANTEC series. Solutions with the KR FORTEC or KR 1000 titan product families – which belong to the heavy-duty category – are also possible. This makes the “robogonio”, despite its size, very flexible – ranging from a payload of 6 kilograms with a 700 millimeter reach to a payload of 1,300 kilograms with a 3,000 millimeter reach – so that it can be adjusted to the individual needs of the customer.

With payloads of 6 or 10 kilograms, the “robogonio” is the ideal solution for measuring both small light sources such as LEDs as well as heavy lighting equipment. In the automotive industry, “robogonios” with 90 kilogram or even 120 kilogram capacity are used if complex front headlight systems need to be measured.

Excellent repeatability and speed

Each “robogonio” features exceptional high angle repeatability while simultaneously achieving extremely high measurement speed. Even the test methods for measuring the increasingly popular LED linear luminaires (e.g. for ambient or door lighting in automobile interiors) can be carried out with the “robogonio”. It can thus quickly adapt to current market trends and flexibly shape them as well. The “robogonio” is equally flexible when used in rooms, laboratories or production halls: Its pivot point can be selected anywhere in the room, and it can be installed vertically or horizontally.